Customizable Versatile Power Supply Transformer for Specialized Applications

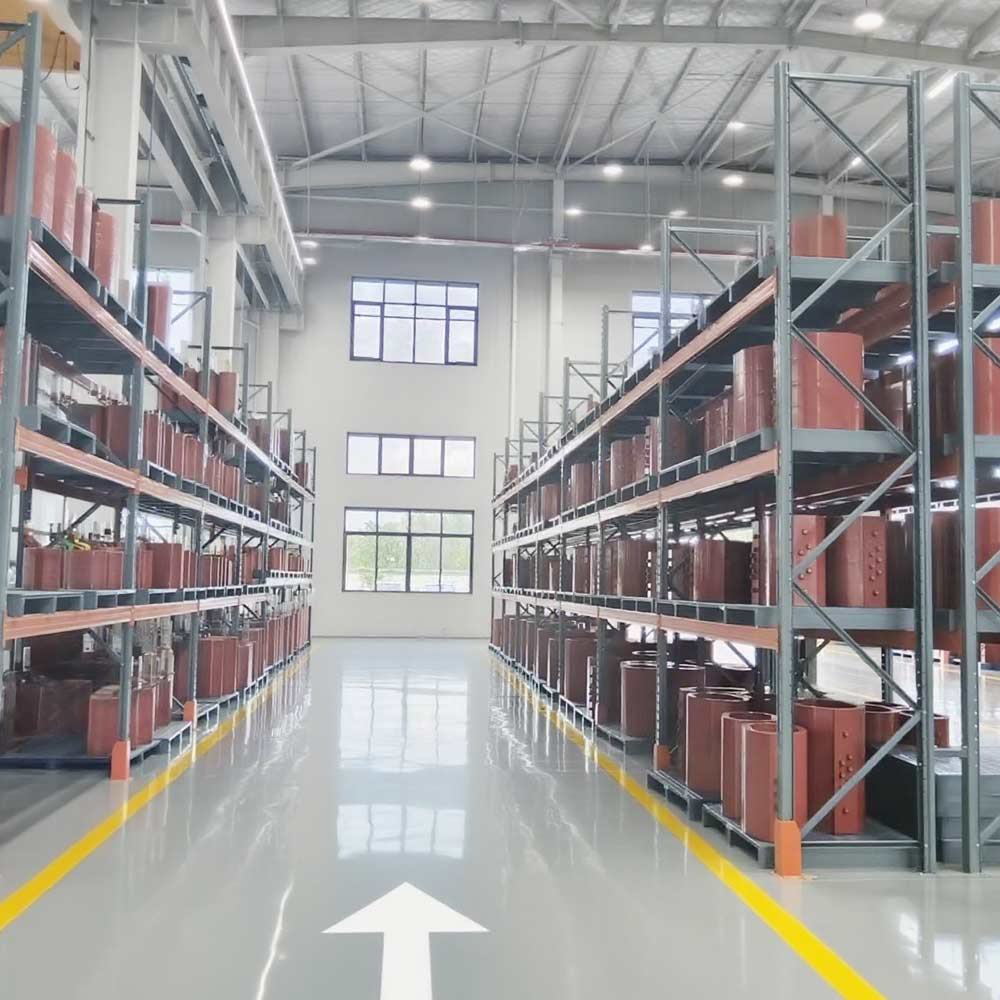

Introducing the latest Power Supply Transformer from Lihe Electrical Equipment. As a leading custom manufacturer with in-house production capabilities, we take pride in offering a top-of-the-line power supply transformer that delivers reliability, efficiency, and cost-effectiveness—three core advantages that directly address your power system needs.

Our power supply transformers are engineered to meet the specific requirements of each customer, with rigorous quality control throughout the production process to ensure the highest level of performance and long-term stability. Backed by our competitive and transparent price list, you can trust that your investment will yield maximum value, without compromising on product quality.

Whether you need a power supply transformer for industrial production lines, commercial complexes, or residential power distribution networks, our team has the technical expertise and production resources to deliver a fully customized solution that fits your unique needs. Trust Lihe Electrical Equipment for all your power supply transformer requirements, and experience the tangible difference our high-quality products bring to your business operations.

Contact us today to learn more about our power supply transformer options and how we can tailor a solution to meet your specific technical and operational requirements.

How Power Supply Transformers Work: The Science of Electromagnetic Induction

At its core, a power supply transformer operates on Faraday’s Law of Electromagnetic Induction—a fundamental principle that governs the transfer of electrical energy between two or more coils (windings) through a shared magnetic core. Here’s a simplified breakdown of its operation:

- Primary Winding: This coil connects directly to the input power source (e.g., the 110V/220V AC grid). When alternating current (AC) flows through it, it generates a changing magnetic field in the transformer’s iron or ferrite core.

- Magnetic Core: Designed to efficiently channel magnetic flux, the core ensures minimal energy loss as the magnetic field oscillates with the AC current.

- Secondary Winding: This separate coil wraps around the same core. The changing magnetic field induces an alternating voltage in the secondary winding—its magnitude depends on the turns ratio (number of coils in the secondary vs. primary).

- A step-down transformer (e.g., from 220V grid to 12V for a desktop PC) has fewer secondary turns, reducing voltage.

- A step-up transformer (e.g., in solar inverters, boosting 48V DC-derived AC to grid-compatible 220V) has more secondary turns, increasing voltage.

Crucially, transformers only work with AC power—since DC current produces a static magnetic field that cannot induce voltage in the secondary winding. This is why AC remains the standard for grid power: it enables safe, efficient voltage conversion via transformers.

Key Functions of Power Supply Transformers: Beyond Voltage Conversion

While voltage adjustment is the most well-known role, power supply transformers provide two additional critical benefits that safeguard equipment and users:

1. Electrical Isolation

The physical separation between primary and secondary windings (no direct electrical connection) creates a galvanic isolation barrier. This prevents dangerous ground loops, shields sensitive electronics from grid noise (e.g., voltage spikes from lightning or industrial machinery), and protects users from electric shock. For example, medical devices like MRI machines rely on isolated transformers to eliminate any risk of current leakage to patients.

2. Voltage Stabilization

Grid power is rarely perfectly consistent—fluctuations (e.g., brownouts, surges) are common. High-quality power supply transformers, paired with additional regulation components (e.g., capacitors, voltage regulators), help smooth these variations. This ensures devices receive a steady voltage output, extending their lifespan and preventing data loss (in computers) or performance errors (in industrial sensors).

Common Types of Power Supply Transformers & Their Applications

Power supply transformers are tailored to specific use cases, with two primary categories dominating modern systems:

| Type | Key Characteristics | 典型应用领域 |

|---|---|---|

| Linear Power Supply Transformers | Low energy efficiency (50-70%), low electromagnetic interference (EMI), simple design, stable output | Audio equipment (speakers, amplifiers), medical devices, precision test instruments |

| Switch-Mode Power Supply (SMPS) Transformers | High efficiency (85-95%), compact size, lightweight, works with wide input voltage ranges | Laptops, smartphones, LED lights, gaming consoles, renewable energy systems (solar/wind inverters) |

Other specialized types include isolation transformers (for medical/industrial safety), autotransformers (single-winding design for small voltage adjustments), and toroidal transformers (compact, low noise—ideal for home theater systems).

Choosing the Right Power Supply Transformer: Critical Considerations

Selecting a transformer requires matching it to your device’s needs and environmental conditions:

- Power Rating: Measured in volt-amperes (VA) or watts (W), it must exceed the device’s maximum power draw (e.g., a 100W laptop charger needs a transformer rated for at least 100W).

- Input/Output Voltage: Ensure compatibility with your local grid (110V in North America, 220V in Europe/Asia) and device requirements (e.g., 5V for USB devices).

- Efficiency: Higher efficiency (e.g., 90%+ for SMPS transformers) reduces energy waste and heat generation—critical for enclosed devices like gaming consoles.

- Safety Certifications: Look for compliance with global standards (UL, CE, IEC) to ensure protection against overheating, short circuits, and electric shock.

Final Thoughts: Why Power Supply Transformers Matter

In an era of smart devices, renewable energy, and industrial automation, the power supply transformer remains invisible but essential. It translates the grid’s “one-size-fits-all” electricity into the precise, safe power that powers our daily lives and drives global industry. Whether you’re charging a phone or operating a factory, understanding its role helps you make informed decisions about equipment reliability, energy efficiency, and safety.

For businesses and engineers, investing in high-quality power supply transformers isn’t just a cost—it’s a safeguard against downtime, equipment failure, and safety hazards. For consumers, it’s the reason your favorite devices work seamlessly, day in and day out.

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer BoxHigh Efficiency 1 MVA Transformer for Utilities

Distribution Transformer10 MVA Dry Type Transformer for Large-Scale Manufacturing Units

Distribution Transformer2000 KVA Oil Filled Transformer for Substation Voltage Conversion

Distribution TransformerThree Phase 1250 KVA Transformer for Substation Distribution

Distribution Transformer315 KVA Dry Type Transformer IEC Compliant for Power Grids

Distribution TransformerLow Loss 4 MVA Transformer for Energy Efficient Operations

Distribution Transformer