Tech-Leading Customizable Expert-Engineered Box Type Substation

Introducing our state-of-the-art Box Type Substation, engineered and manufactured by Lihe Electrical Equipment. Our custom-built box type substations are ideal for diverse scenarios—from residential communities and commercial districts to industrial parks and remote infrastructure projects—providing a compact, space-saving, and highly efficient solution for power distribution needs.

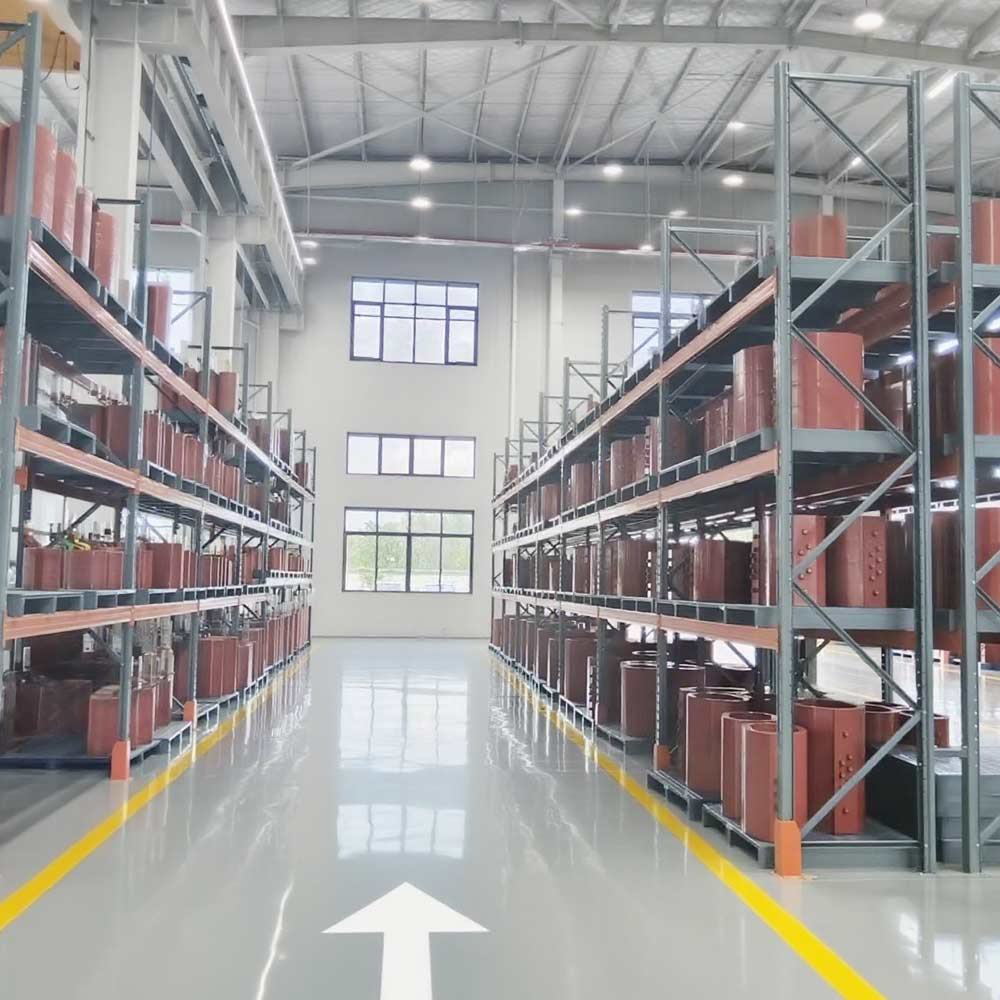

Our production facility crafts these substations in strict adherence to the highest quality standards: every component (from internal transformers to switchgear) undergoes rigorous testing to ensure reliable long-term performance and durability, even in harsh outdoor environments like high-temperature or humid areas. We offer a wide range of configurable options to tailor the substation to your exact requirements—whether it’s adjusting capacity for a small residential area, adding weatherproofing for outdoor use, or integrating intelligent monitoring systems for real-time power management—making it a cost-effective and versatile choice for your project.

Whether you need a standard design for quick deployment or fully customized specifications to match unique project demands, our team provides support throughout the process, paired with a competitive and transparent price list. Trust Lihe Electrical Equipment for all your box type substation needs, and experience the advantage of working with a leading manufacturer dedicated to delivering practical power solutions.

Box Type Substations (BTS), also known as prefabricated substations, are revolutionizing power distribution by integrating high-voltage switchgear, transformers, low-voltage switchgear, and control systems into a single, enclosed unit. Designed for both indoor and outdoor use, they address the growing demand for space-saving, rapid-deployment power solutions across industries—from urban infrastructure to renewable energy projects.

Unlike traditional substations that require on-site construction (often taking months), BTS units are factory-assembled, tested, and pre-wired. This prefabrication cuts installation time by 60-80%, reduces on-site labor costs, and ensures consistent quality compliance with global standards (e.g., IEC 62271, ANSI C57.12, GB/T 17467). Their robust enclosures—made of galvanized steel or composite materials—offer IP54/IP65 protection, shielding internal components from dust, moisture, and extreme temperatures, making them ideal for harsh environments.

Key Applications

BTS units excel in scenarios where speed, space, and reliability matter:

- Urban Areas: Powering residential complexes, commercial malls, and data centers where land is scarce.

- Renewable Energy: Connecting solar farms or wind parks to the grid, as their compact design fits into remote locations.

- Temporary Projects: Supporting construction sites, emergency relief efforts, or large events with portable, quick-to-deploy power.

- Industrial Zones: Supplying stable power to factories or manufacturing plants, with customizable configurations to match load demands.

Core Benefits

- Cost-Efficiency: Eliminates on-site construction delays and reduces long-term maintenance costs due to factory-calibrated components.

- Flexibility: Customizable voltage ratings (10kV-35kV input, 0.4kV output) and load capacities to meet specific project needs.

- Safety: Integrated insulation, grounding, and fault-protection systems minimize electrical hazards, complying with strict safety regulations.

- Eco-Friendliness: Compact footprint reduces land disturbance, and modern models include energy-efficient transformers (e.g., amorphous core) to lower power loss.

In short, Box Type Substations are the backbone of modern power distribution. Their blend of speed, efficiency, and durability makes them a go-to choice for utilities, engineers, and project managers looking to streamline power delivery—without compromising on performance or safety.

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer BoxHigh Efficiency 1 MVA Transformer for Utilities

Distribution Transformer10 MVA Dry Type Transformer for Large-Scale Manufacturing Units

Distribution Transformer2000 KVA Oil Filled Transformer for Substation Voltage Conversion

Distribution TransformerThree Phase 1250 KVA Transformer for Substation Distribution

Distribution Transformer315 KVA Dry Type Transformer IEC Compliant for Power Grids

Distribution TransformerLow Loss 4 MVA Transformer for Energy Efficient Operations

Distribution Transformer

electrical substation equipment, power supply substation, 5000kva substation transformer, oil immersed distribution transformers, transformador de 200kva, pad mounted transformer box, 10Mva power transformer, dry type transformer coil, main power transformer, 34500v pad mount transformer, 2500kva Transformer