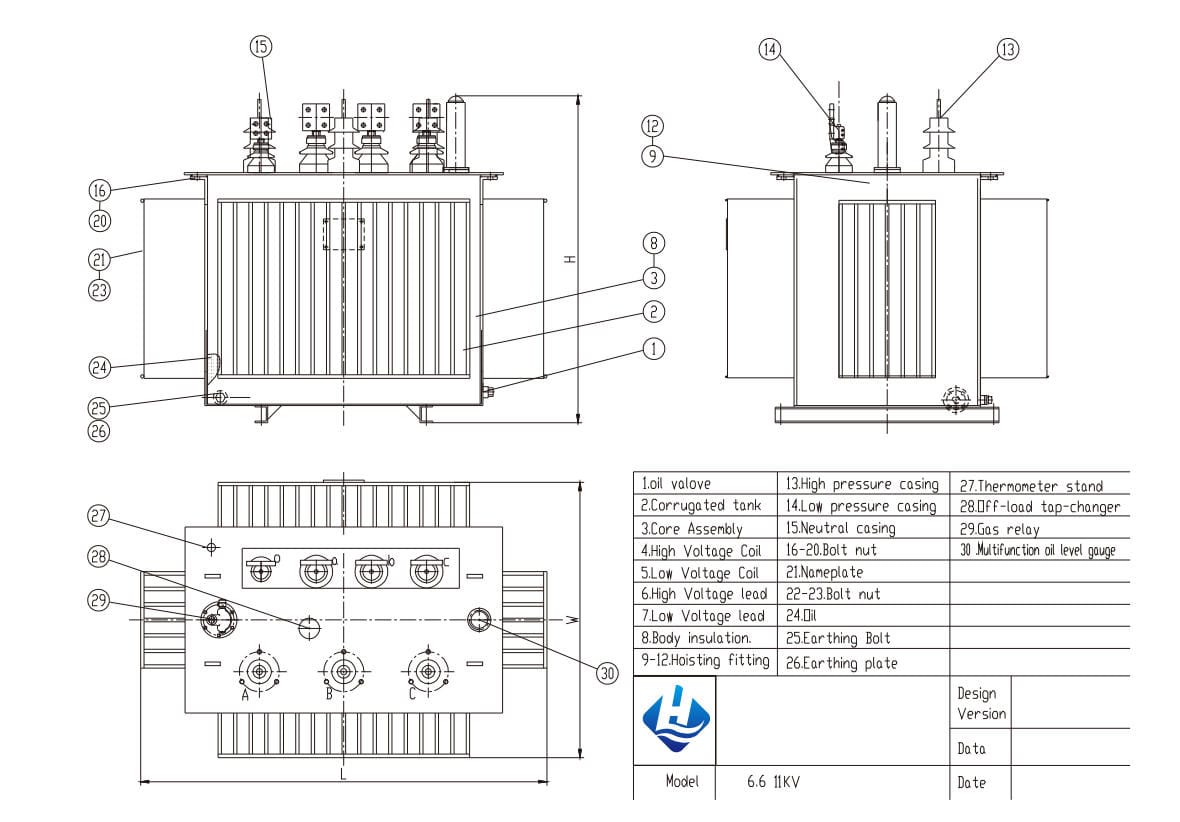

Overview of Structural diagram of Oil Filled Transformer

Ever wondered how the intricate components of an oil filled transformer work together to ensure reliable power transmission? Our comprehensive overview of oil filled transformer structural diagrams is your key to mastering every detail—from core to tank, windings to cooling systems.

Designed for engineers, technicians, and industry professionals, this guide breaks down each critical part: the magnetic core that enables energy transfer, insulated windings that handle voltage conversion, oil-filled tanks that provide cooling and insulation, and auxiliary components like bushings, conservators, and radiators. Learn how these elements interact to optimize efficiency, enhance safety, and extend transformer lifespan in power grids, industrial plants, and commercial facilities.

Whether you’re troubleshooting performance issues, planning maintenance, or selecting the right transformer for your project, understanding its structural diagram is non-negotiable. Our expert analysis clarifies complex designs, highlights common structural variations, and connects diagram details to real-world functionality—so you can make informed decisions with confidence.

Advantages of Oil Filled Transformer

- Flexible standard adaptation: Supports international standards such as GB, IEC, and UL, with customization available based on customer requirements;

- Multi-national authoritative certifications: Certified by ISO, CE, UL, etc., ensuring reliable quality;

- High efficiency: Exceeds 99% efficiency, complying with the European Tier 2 energy efficiency regulation (2015/2014/548/EC) for excellent energy savings;

- Maintenance-free operation: Features IP65 protection class for dust and moisture resistance, with a design life of over 25 years for hassle-free use;

- Environmental friendliness: Optional FR3 vegetable oil, meeting environmental protection and sustainable development needs;

- Strong overload capacity: Copper coil design allows short-term overload up to 150% of rated capacity (maximum 2 hours), with only oil temperature monitoring required (≤95℃).

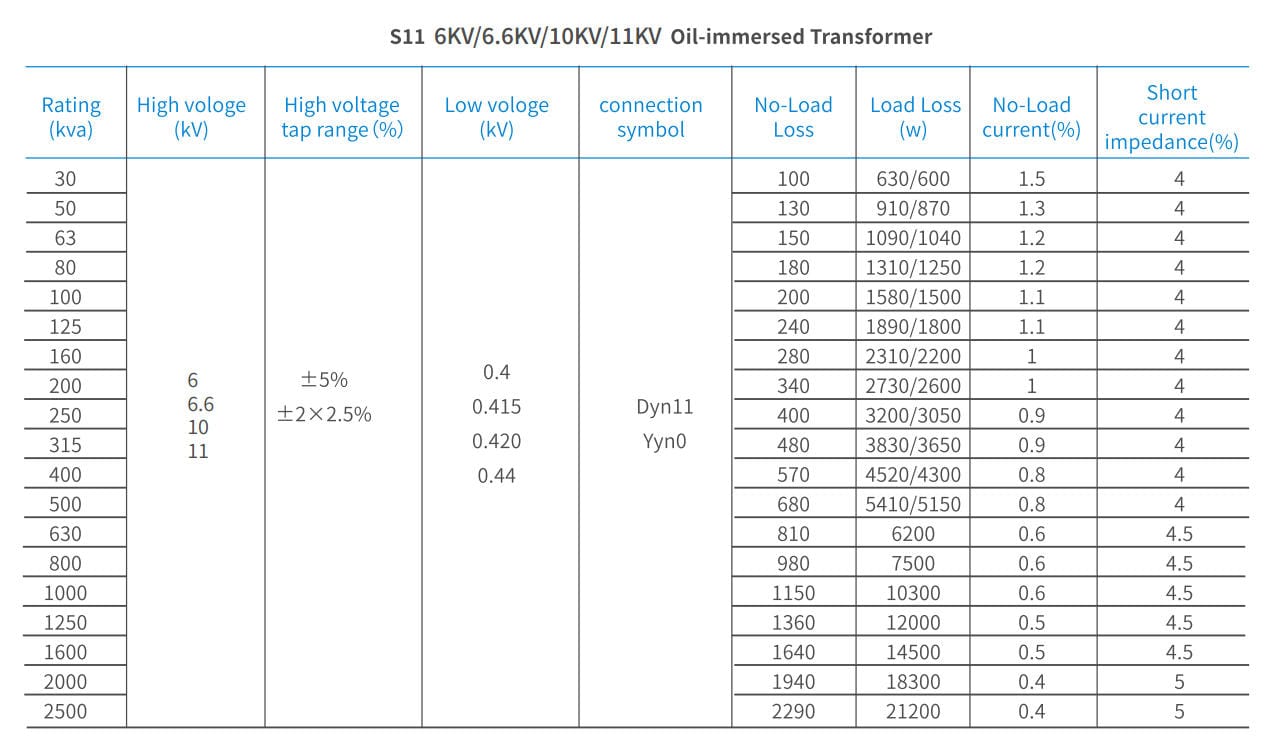

Oil Filled Transformer Technical Parameters

Oil Filled Transformer Case Display

Dive into our oil filled transformer case display to see how we’ve powered success for clients worldwide. From large-scale power grids to specialized industrial setups, our case studies showcase the reliability, efficiency, and adaptability of our oil filled transformers in real-world scenarios.

Oil Filled Transformer Business Cooperation

Our oil filled transformers—engineered for durability, efficiency, and compliance with global standards (ISO, CE, IEC)—cater to diverse sectors: power distribution, renewable energy, industrial plants, and utility grids. Whether you need standard models or custom solutions tailored to specific voltage, capacity, or environmental requirements, our R&D team works closely with partners to deliver products that exceed expectations.

评价

There are no reviews yet.