What is the difference between dry type transformer and oil?

What is the difference between dry type transformer and oil?

In power transmission and distribution systems, transformers serve as the core equipment for voltage conversion, directly impacting grid stability, operational costs, and safety.

Oil-immersed and dry-type transformers are the two most widely used types, each with distinct structural designs and performance characteristics. This article provides a professional analysis of their advantages, disadvantages, and application scenarios to guide optimal selection.

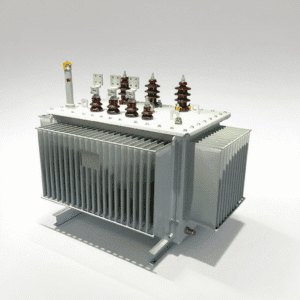

Oil-Immersed Transformers: Traditional Power Solutions with Insulating Oil

Oil-immersed transformers use insulating oil (mineral oil or vegetable-based oil) as both the cooling and insulating medium. As the most mature transformer type in the power industry, they dominate high-voltage and large-capacity applications.

Technical Principles and Structural Features

The core design leverages the physical properties of insulating oil for dual functions:

- Enhanced Insulation: Insulating oil has a breakdown voltage (25-35kV/mm) far exceeding air (3kV/mm), effectively isolating high-voltage windings from grounded enclosures.

- Efficient Heat Dissipation: Through natural convection or forced circulation (with oil pumps), the oil transfers heat from the core and windings to the tank walls or external radiators.

Key components include:

- Main Parts: Core, high/low-voltage windings.

- Auxiliary Systems: Oil tank, conservator, breather, and explosion vent. The conservator compensates for oil volume changes, the breather adsorbs moisture, and the explosion vent releases pressure during emergencies.

Advantages of Oil-Immersed Transformers

- High Capacity and Efficiency

With a thermal conductivity 3-4 times that of air, oil enables large-capacity designs (from hundreds of kVA to tens of MVA). Efficiency reaches 95%-99.5% under full load, ideal for power plants and long-distance transmission. - Superior Insulation Stability and Long Lifespan

The sealed tank environment protects windings from moisture and dust, extending the lifespan to 20-30 years (or over 40 years for premium models), outlasting many dry-type transformers.

- High Capacity and Efficiency

- Strong Overload Capacity

It can handle 120%-150% of rated load for short periods (30-60 minutes) and is suitable for fluctuating industrial loads or seasonal demand peaks. - Lower Lifecycle Cost

Manufacturing costs are 20%-40% lower than dry-type transformers for the same capacity. Even with regular maintenance, the total cost of ownership remains competitive.

Limitations of Oil-Immersed Transformers

- Safety and Environmental Risks

Traditional mineral oil is flammable (flash point 140-160°C), posing fire hazards if leaked. Spills also contaminate soil and water. While biodegradable vegetable oils mitigate risks, they cost 30% more. - Installation Constraints

Large size and weight (e.g., 1.5-2 tons for a 1000kVA unit, 1.5-2 times heavier than dry-type) require dedicated foundations or outdoor spaces, unsuitable for cramped indoor environments like high-rise basements. - Complex Maintenance

Regular oil testing (dielectric loss, moisture, breakdown voltage) and filtration/replacement every 1-2 years increase maintenance labor and costs.

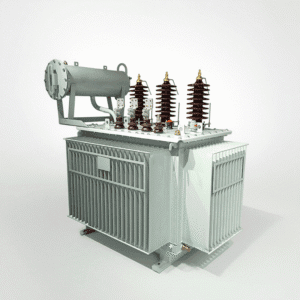

Dry-Type Transformers: Modern Oil-Free Power Solutions

Dry-type transformers use air or inert gas for cooling and solid insulation

materials (e.g., epoxy resin, Nomex paper), making them ideal for indoor and environmentally sensitive applications.

Technical Principles and Structural Features

Heat dissipation relies on natural air convection or forced air cooling. The insulation system consists entirely of solid materials:

- Winding Insulation: Cast resin transformers encase windings in epoxy for moisture and dust resistance; impregnated transformers coat windings with insulating varnish.

- Core Design: Similar to oil-immersed types but uses lower-loss

silicon steel (e.g., 30Q130) to reduce heat generation.

Common types include epoxy cast resin (most prevalent, ~80% market share), open-frame, and encapsulated designs, with cast resin dominating in harsh environments.

Advantages of Dry-Type Transformers

- Superior Safety and Environmental Compatibility

No flammable oil eliminates fire risks, making them suitable for high-rise buildings, hospitals, data centers, and subway stations. They also meet strict environmental regulations with zero oil leakage. - Compact Size and Flexible Installation

30%-40% smaller and lighter than oil-immersed units of the same capacity, enabling installation in indoor switchgear, on floors, or brackets, saving valuable space in urban areas. - Low Maintenance Requirements

Eliminate oil testing and replacement. Routine maintenance involves annual dust cleaning and connection checks, reducing labor costs, especially in high-wage regions. - Excellent Environmental Adaptability

Epoxy-encased windings withstand humidity up to 90% (non-condensing) and dusty environments, making them ideal for basements, coastal areas, and industries like textiles or food processing.

Limitations of Dry-Type Transformers

- Limited Cooling Efficiency and Capacity

Air’s low thermal conductivity (0.026W/(m·K)) restricts capacity to ≤2500kVA (natural cooling) or ≤5000kVA (forced air), insufficient for large industrial plants or high-voltage substations. - Environmental Sensitivity

Solid insulation ages faster under high temperatures (>100°C) or humidity (condensation). Dust accumulation on windings can cause partial discharges, shortening lifespan. - Weaker Overload Capacity

Can only handle 110%-120% of rated load for ≤30 minutes, unsuitable for applications with frequent load fluctuations. - Higher Initial Cost

Premium materials and manufacturing processes increase costs by 30%-50% compared to oil-immersed transformers, particularly for small-capacity units (<500kVA).

Comparative Analysis and Selection Strategies

The choice between oil-immersed and dry-type transformers depends on specific application requirements rather than generic “advantages.”

Key Performance Comparison Table

Parameter | Oil-Immersed Transformers | Dry-Type Transformers |

Cooling Medium | Insulating oil (mineral/vegetable) | Air/inert gas |

Rated Capacity | Hundreds of kVA to tens of MVA | Tens of kVA to 5000 kVA |

Typical Installation | Outdoor substations, industrial areas | Indoor switchgear, high-rise buildings |

Safety Risk | Medium (fire and pollution risks) | Low (no flammable components) |

Lifecycle Cost | Lower (lower purchase, moderate maintenance) | Higher (higher purchase, lower maintenance) |

Short-Term Overload | 120%-150% (30-60 minutes) | 110%-120% (15-30 minutes) |

Environmental Adaptability | Dry, open spaces | Humid, enclosed, dusty environments |

Application-Specific Selection Guide

Opt for Oil-Immersed Transformers When:

- Outdoor high-voltage transmission: Substations above 110kV, long-distance power lines.

- Large industrial complexes: Steel, chemical, or mining facilities with high and fluctuating loads.

- Remote areas with cost constraints: Rural grid upgrades, temporary mining sites.

Opt for Dry-Type Transformers When:

- Indoor sensitive environments: High-rise buildings, hospitals, data centers, subway stations.

- Hazardous industrial zones: Petrochemical, textile, or flour processing plants requiring explosion-proof equipment.

- Space-constrained installations: Underground substations, marine vessels, or urban indoor locations.

Conclusion

Oil-immersed transformers remain dominant in outdoor high-voltage systems due to their high capacity, efficiency, and cost-effectiveness. Dry-type transformers excel in safety-critical indoor environments. Emerging technologies are blurring the lines—vegetable oil reduces environmental risks for oil-immersed units, while forced-air-cooled dry-type transformers now exceed 10MVA capacity.

Future selection will prioritize “scenario compatibility,” considering voltage class, capacity, installation environment, safety standards, and lifecycle costs. The ultimate goal is to ensure safe, efficient, and economical operation of power systems.