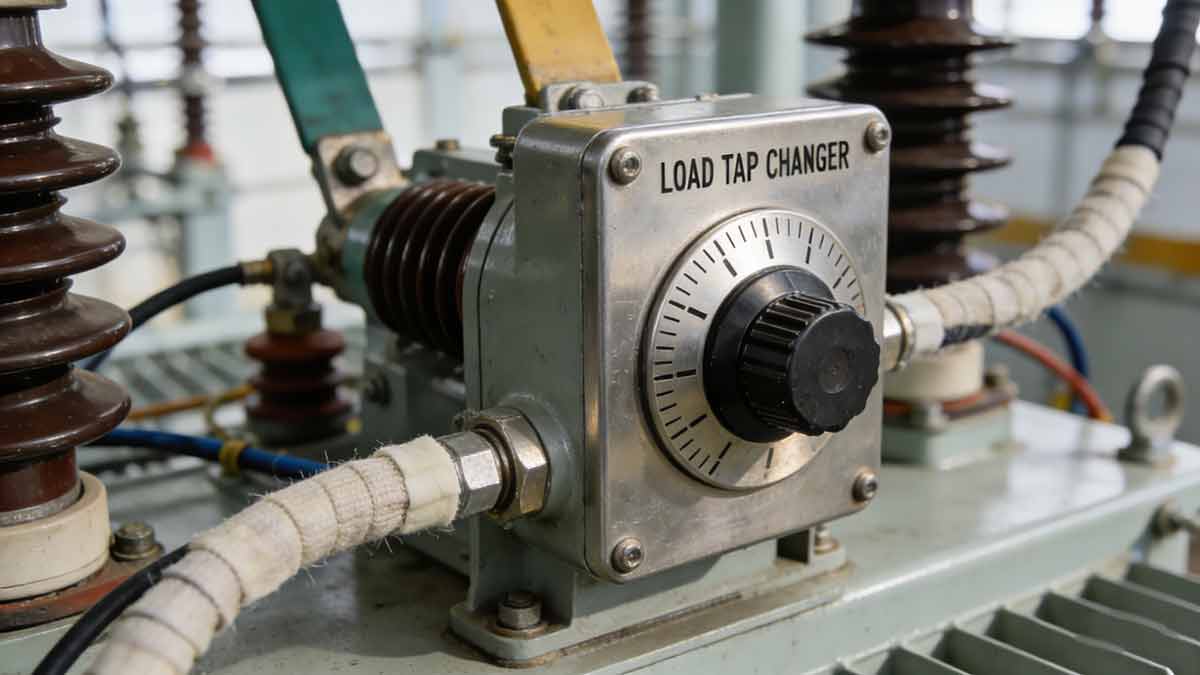

Load Tap Changer: Core Definition and Its Role in Power Systems

At its essence, a load tap changer (LTC) is an integral component installed within power transformers, designed specifically to adjust voltage levels without interrupting the transformer’s operation. To grasp its importance, we must first recall a fundamental principle of electrical systems: most electrical equipment and end-use devices require a consistent, specified voltage range to function optimally and safely. Deviations from this range—whether voltage sags (too low) or surges (too high)—can lead to a cascade of issues: reduced energy efficiency, premature wear and tear on sensitive equipment, operational downtime, and in extreme cases, widespread blackouts.

The load tap changer addresses this critical challenge by modifying the transformer’s turns ratio through “tap connections” on the transformer’s winding. These taps are preconfigured points along the winding that allow for incremental adjustments to the voltage output. Unlike basic voltage regulators, the defining advantage of an LTC is its ability to make these adjustments while the transformer is energized and under full load—eliminating the need for power interruptions. This continuous operability makes it an irreplaceable component in systems where uptime is non-negotiable, such as public power grids, critical industrial processes, and healthcare facilities.

Why Voltage Regulation Is Non-Negotiable for Power Systems

Voltage fluctuations are inevitable in power systems, driven by factors like varying consumer demand (e.g., peak usage during morning and evening hours), changes in power generation (especially with variable renewable sources like wind and solar), and transmission losses over long distances. Without effective regulation, these fluctuations can have severe consequences:

Equipment Damage: Sensitive electronic devices (e.g., industrial control systems, medical equipment, and data center servers) are particularly vulnerable to voltage spikes, which can burn out circuits or corrupt components. Low voltage, on the other hand, can cause motors to overheat and fail due to increased current draw.

Energy Waste: When voltage is too high, equipment consumes more energy than necessary, leading to higher utility costs and increased carbon emissions. When too low, systems may operate below their rated efficiency, wasting energy on subpar performance.

System Instability: Unregulated voltage can trigger cascading failures in power grids, as overloaded components trip protective relays, leading to localized or widespread outages. This is especially critical in interconnected power networks that serve millions of consumers.

By maintaining voltage within the optimal range, load tap changers act as “stabilizers” for the power system, mitigating these risks and ensuring that electricity is delivered reliably and efficiently.

How Does a Load Tap Changer Work? Operational Mechanisms Explained

To understand the functionality of a load tap changer, it helps to use a relatable analogy: think of adjusting the brightness of a dimmable light. Just as a dimmer switch modifies the amount of electrical current flowing to the bulb (changing its brightness without turning it off), an LTC adjusts the transformer’s turns ratio (the ratio of primary to secondary winding turns) to modify voltage output—all while the transformer remains energized and supplying power.

The Basics of Transformer Taps and Turns Ratio

Power transformers work by transferring electrical energy between two or more windings through electromagnetic induction. The voltage output of a transformer is directly proportional to its turns ratio: Voltage (Secondary) = Voltage (Primary) × (Number of Secondary Turns / Number of Primary Turns). Taps are additional connection points along the transformer’s winding that allow for small adjustments to the number of turns in use. For example, a tap might reduce the number of secondary turns by 2%, which would lower the secondary voltage by approximately 2% (assuming the primary voltage remains constant).

A load tap changer’s core function is to switch between these taps seamlessly. Unlike manual tap adjustments (which require the transformer to be de-energized), LTCs use mechanical and electrical mechanisms to switch taps without interrupting the current flow. This is achieved through a combination of switching contacts, arcing suppressors (to prevent electrical sparks during switching), and control systems that monitor voltage levels and trigger adjustments as needed.

Key Operational Features of Load Tap Changers

The most critical feature of an LTC is its ability to perform “on-load” adjustments. This is made possible by two primary design elements:

Transition Mechanism: LTCs use a transition switch (or diverter switch) that temporarily connects two taps during the switching process. This ensures that current continues to flow through the transformer while the tap is changed, eliminating power gaps. Arcing suppressors (such as resistors or reactors) are integrated into this mechanism to absorb the electrical energy generated during switching, preventing damage to the contacts and ensuring safe operation.

Control System: Modern LTCs are equipped with automated control systems that continuously monitor the transformer’s output voltage. These systems can be set to maintain a specific voltage level or adjust based on preprogrammed parameters (e.g., changes in load demand). Some advanced LTCs also integrate with smart grid technologies, allowing for remote monitoring and control.

The combination of these features ensures that load tap changers can make precise, frequent voltage adjustments without disrupting power supply—critical for systems that require 24/7 operability.

Types of Load Tap Changers: OLTC vs. NLTC

While all load tap changers serve the same core purpose (voltage regulation), they are categorized into two main types based on whether they operate while the transformer is energized: On-Load Tap Changers (OLTC) and No-Load Tap Changers (NLTC). Understanding the differences between these types is essential for selecting the right solution for a specific application, as each is designed for distinct operational requirements.

On-Load Tap Changer (OLTC): Continuous Regulation for Critical Systems

On-Load Tap Changers (OLTCs) are the most common type of LTC, designed to adjust voltage while the transformer is fully energized and under load. As the name suggests, they operate without requiring the transformer to be shut down, making them ideal for applications where uninterrupted power is critical. OLTCs are equipped with the advanced transition mechanisms (resistors/reactors and diverter switches) discussed earlier, allowing for smooth, spark-free switching between taps.

Key applications of OLTCs include:

Public power distribution grids (where outages affect thousands of consumers)

Critical industrial processes (e.g., semiconductor manufacturing, chemical plants, and automotive production lines)

Healthcare facilities (hospitals, clinics) and data centers (where downtime can have life-threatening or financial consequences)

Renewable energy installations (e.g., wind farms, solar parks) where power generation is variable and requires real-time voltage adjustment

OLTCs are available in a range of configurations, including oil-immersed (the most common, as oil provides insulation and cooling) and dry-type (used in indoor applications where oil is not feasible). They are also rated for different voltage levels and load capacities, making them suitable for both low-voltage industrial systems and high-voltage transmission networks.

No-Load Tap Changer (NLTC): Cost-Effective for Non-Critical Applications

No-Load Tap Changers (NLTCs) are designed to adjust voltage only when the transformer is de-energized and not under load. Unlike OLTCs, they do not require complex transition mechanisms, as the absence of current during switching eliminates the risk of arcing. This makes NLTCs simpler in design, more cost-effective, and easier to maintain than OLTCs. However, their major limitation is the need for a power interruption to make adjustments.

Key applications of NLTCs include:

Residential and commercial buildings (where occasional power outages for maintenance are acceptable)

Small industrial facilities with non-critical processes (e.g., warehouses, small manufacturing units)

Applications with infrequent voltage fluctuations (e.g., rural power lines with stable load demand)

NLTCs are often used as a cost-saving alternative to OLTCs in scenarios where continuous voltage regulation is not required. They are typically manually adjusted, though some models can be automated with simple control systems for remote operation (still requiring de-energization before switching).

Key Benefits of Load Tap Changer in Power Systems

The integration of a load tap changer into a power system delivers a wide range of benefits, all centered around improving reliability, efficiency, and equipment longevity. These benefits are particularly impactful in modern power systems, which face growing demands from increasing consumer use, the integration of renewable energy, and the need for grid resilience. Below are the three most significant advantages:

1. Enhanced System Reliability and Uptime

By maintaining voltage within the optimal range, load tap changers prevent voltage-related failures that can lead to system outages. For example, in power distribution grids, OLTCs adjust for transmission losses over long distances (which cause voltage drops) and peak load demand (which can trigger voltage sags). This ensures that consumers receive a consistent power supply, reducing the frequency and duration of blackouts. In critical applications like hospitals and data centers, this reliability is life-saving and financially critical—downtime in these sectors can cost millions of dollars per hour.

2. Improved Energy Efficiency and Reduced Waste

Voltage fluctuations force electrical equipment to operate outside of its rated efficiency range. For instance, a motor operating at 10% below its rated voltage will draw more current to compensate, increasing energy consumption and generating excess heat. Load tap changers eliminate this inefficiency by keeping voltage stable, ensuring that equipment operates at its optimal performance level. This not only reduces energy waste but also lowers utility costs for consumers and businesses. In large-scale power grids, even a small improvement in efficiency can translate to significant energy savings and reduced carbon emissions.

3. Protection of Sensitive Electrical Equipment

Modern electrical equipment—from industrial control systems to consumer electronics—is increasingly sensitive to voltage variations. Voltage spikes can damage microchips, capacitors, and other components, while sustained low voltage can cause motors to overheat and fail. Load tap changers act as a “shield” for this equipment, preventing damage and extending its lifespan. This reduces maintenance costs and replacement expenses for businesses and consumers, making power systems more cost-effective in the long run.

Applications of Load Tap Changer: Where Are They Used?

Load tap changers are versatile components used across a wide range of power system applications, from large-scale public grids to small industrial setups. Their ability to regulate voltage continuously (in the case of OLTCs) or cost-effectively (in the case of NLTCs) makes them indispensable in any scenario where voltage stability is critical. Below are the most common application areas:

Power Distribution Networks

Public power distribution networks are the largest users of load tap changers. These networks transmit electricity from power plants to homes, businesses, and industries over long distances, and voltage drops are inevitable due to resistance in transmission lines. OLTCs are installed in distribution transformers to adjust for these drops, ensuring that voltage remains consistent at the point of consumption. For example, a transformer located at the edge of a city might use an OLTC to compensate for voltage losses in the lines connecting it to the power plant, ensuring that residents receive the 120V (or 230V, depending on the region) required for household appliances.

Industrial Facilities

Industrial facilities rely on heavy machinery, control systems, and automated equipment—all of which require stable voltage to operate safely and efficiently. Load tap changers (primarily OLTCs) are used in industrial transformers to regulate voltage for processes like manufacturing, mining, and chemical production. For example, in a semiconductor factory, even minor voltage fluctuations can damage delicate microchips during production. An OLTC ensures that voltage remains constant, preventing costly defects and downtime.

Renewable Energy Integrations

The growth of renewable energy sources (wind, solar, hydro) has introduced new challenges to power systems, as these sources generate variable power output (e.g., wind speed fluctuates, solar panels depend on sunlight). Load tap changers play a critical role in integrating these sources into the grid by adjusting voltage to accommodate the variable power input. For example, a wind farm might use OLTCs in its transformers to regulate voltage as wind speeds change, ensuring that the power fed into the grid is stable and compatible with existing infrastructure. This helps to maximize the use of renewable energy while maintaining grid reliability.

Critical Infrastructure

Critical infrastructure like hospitals, airports, and military facilities require 24/7 uninterrupted power. Load tap changers (OLTCs) are essential in these settings to ensure that voltage remains stable, even during peak demand or power grid fluctuations. For example, hospitals use OLTCs to power life support equipment, operating rooms, and medical imaging systems—all of which cannot tolerate power interruptions or voltage variations.

Maintenance Requirements for Load Tap Changer: Ensuring Longevity and Performance

While load tap changers are highly reliable components, they are mechanical devices with moving parts (e.g., switches, contacts) that require regular maintenance to ensure optimal performance. Neglecting maintenance can lead to premature failure, which can cause system outages, equipment damage, and costly repairs. Below are the key maintenance practices for load tap changers:

Routine Inspections and Testing

Regular inspections are critical to identifying potential issues early. For OLTCs (the most complex type), inspections should include:

Visual Inspections: Checking for signs of wear, corrosion, or damage to contacts, switches, and insulation. For oil-immersed OLTCs, inspecting the oil for contamination (e.g., water, dirt) and testing its dielectric strength (to ensure it provides adequate insulation).

Electrical Testing: Measuring contact resistance (to ensure good electrical connections), testing the transition mechanism (to verify smooth switching), and monitoring voltage regulation performance (to ensure the LTC is adjusting correctly).

Mechanical Testing: Checking the operation of the diverter switch, ensuring that moving parts are properly lubricated, and verifying that the control system is functioning as intended.

NLTCs require less frequent inspections, but visual checks of taps and connections should still be performed periodically (e.g., annually) to ensure no corrosion or loose connections.

Replacement of Worn Components

Over time, components like contacts, resistors, and insulation can wear out due to repeated use. These components should be replaced at the first sign of wear to prevent failure. For example, worn contacts can cause increased resistance, leading to overheating and potential arcing. Regular testing (e.g., contact resistance measurements) can identify these issues before they escalate.

Lubrication and Cleaning

Mechanical parts of load tap changers (e.g., switches, gears) require regular lubrication to reduce friction and prevent wear. Additionally, cleaning contacts and other components can prevent the buildup of dirt, dust, or oil residue, which can interfere with electrical connections and switching performance.

Training for Operators and Maintenance Personnel

Proper operation and maintenance of load tap changers require specialized knowledge of electrical systems and LTC design. Operators and maintenance personnel should receive comprehensive training to understand how to monitor the LTC, perform routine inspections, and troubleshoot issues. This training ensures that maintenance is performed correctly and safely, reducing the risk of human error.

Proactive Maintenance Schedules

The frequency of maintenance depends on the type of LTC (OLTC vs. NLTC) and its application. For OLTCs in critical applications (e.g., power grids, hospitals), maintenance should be performed every 6–12 months. For NLTCs or OLTCs in less demanding applications, annual or bi-annual maintenance may be sufficient. Creating a proactive maintenance schedule (rather than waiting for failures) extends the lifespan of the LTC and ensures consistent performance.

Conclusion: Why Load Tap Changer Is Indispensable for Modern Power Systems

Answering the question “What is a load tap changer?” reveals its status as a cornerstone of modern power systems. From regulating voltage to ensure equipment safety and efficiency, to enabling the integration of renewable energy and maintaining an uninterrupted power supply, load tap changers play a critical role in supporting the reliability and resilience of electrical infrastructure. Whether it’s an OLTC ensuring 24/7 uptime in a hospital or an NLTC providing cost-effective regulation in a small business, these components are tailored to meet the diverse needs of power systems worldwide.

To maximize the benefits of load tap changers, it’s essential to select the right type (OLTC vs. NLTC) for the application, follow proactive maintenance practices, and ensure that operators and maintenance personnel have the necessary training. By doing so, power system professionals can ensure that their systems operate efficiently, reliably, and safely—meeting the growing demands of modern society for consistent, sustainable electricity.

In summary, the load tap changer is more than just a component—it’s a vital tool for maintaining the balance and stability of power systems. As the world transitions to cleaner energy sources and more complex electrical infrastructure, the importance of load tap changers will only continue to grow.