What Are the Common Power Transformer Faults and How to Troubleshoot Them Effectively?

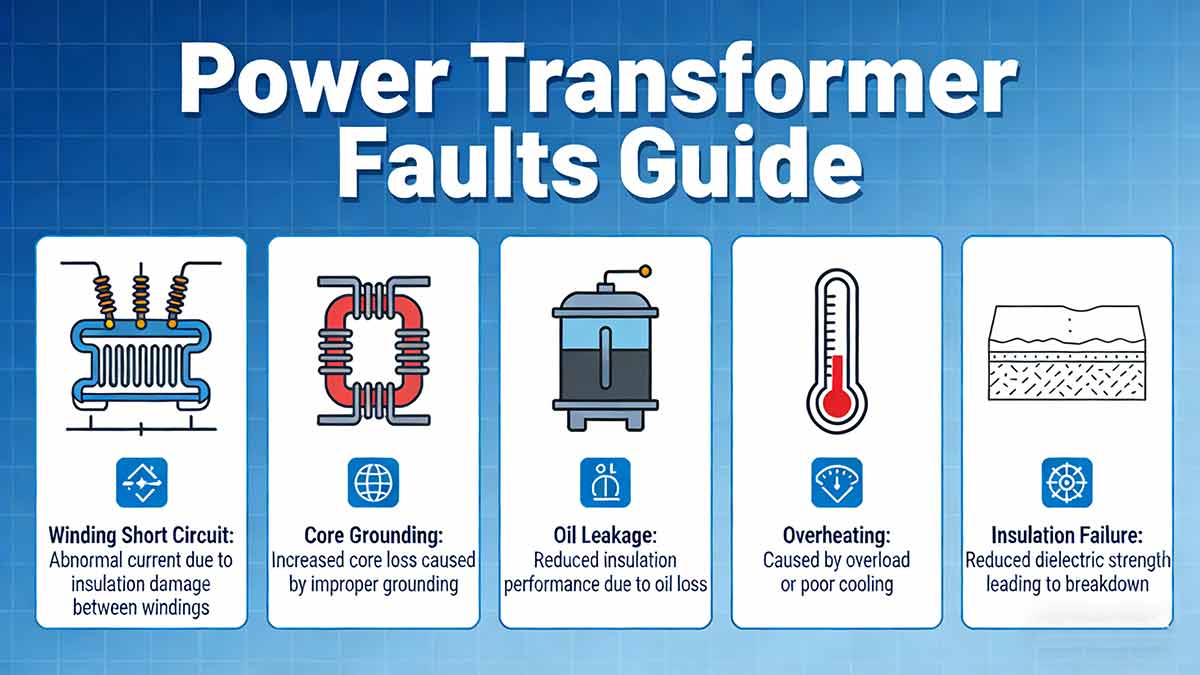

Power transformers serve as the backbone of electrical distribution networks, facilitating the safe and efficient transmission of electricity across varying voltage levels. Any unexpected power transformer faults can trigger cascading failures, leading to prolonged power outages, substantial economic losses, and even safety hazards. For power utility companies, industrial facilities, and transformer maintenance teams, identifying the root causes of transformer malfunctions and implementing targeted solutions is critical to minimizing operational downtime and ensuring grid stability.

Overheating-Related Power Transformer Faults and Resolution Tactics

Core Triggers and Symptom Identification

| Trigger Category | Key Contributing Factors | Distinct Symptoms | Risk Severity |

|---|---|---|---|

| Excessive Load | Sustained operation beyond rated capacity, unbalanced three-phase loads, sudden surge in downstream power demand | Gradual rise in top oil temperature, increased winding temperature deviation, and audible humming that grows louder over time | Medium-High (prolonged exposure leads to insulation breakdown) |

| Cooling System Breakdown | Clogged heat dissipation fins, failed cooling fans/pumps, insufficient coolant (oil or air) supply, blocked coolant pipelines | Rapid temperature spike, winding temperature rising faster than oil temperature, and cooling system indicator lights showing abnormal status | High (fast-onset damage to internal components) |

| Internal Component Defects | Winding short circuits, core laminations, insulation damage, loose electrical connections, tap changer contact failures | Abnormal single-phase temperature rise, localized hot spots detected via infrared scanning, unusual odor of burnt insulation | Critical (may lead to internal arcing and oil decomposition) |

Systematic Troubleshooting and Mitigation Procedures

Immediate Load Reduction and Cooling Restoration

The first step is to decrease the transformer’s load to below the rated capacity by shedding non-critical downstream loads. This action alleviates the excessive thermal stress on the core and winding components. Simultaneously, inspect the cooling system to identify and resolve obvious issues, such as restarting tripped cooling fans, clearing debris from heat exchangers, or refilling depleted coolant reservoirs.

Targeted Oil Chromatographic Analysis

If single-phase temperature remains abnormally high or the top oil temperature continues to climb despite load reduction, immediate oil sampling for chromatographic analysis is mandatory. This test detects the presence of characteristic gases (such as methane, ethylene, and acetylene) produced by internal component degradation. Elevated concentrations of these gases are clear indicators of hidden internal faults, such as winding insulation deterioration or core overheating.

Emergency Shutdown Protocol for Confirmed Internal Faults

If the oil chromatography results confirm the existence of internal defects, the transformer must be taken out of service immediately. Continuing to operate the unit under such conditions will exacerbate component damage and significantly increase the risk of oil ignition or transformer explosion. Post-shutdown, a comprehensive inspection of internal windings, core, and tap changers should be conducted to pinpoint the exact fault location for repair.

Cooling Device Malfunctions in Power Transformers: Diagnosis and Fixes

Step-by-Step Fault Diagnosis Process

Determine the Scope of Cooling System Outage

First, identify whether the malfunction affects individual cooling units, an entire group of units, or all three-phase cooling systems. For example, a single failed fan may only cause a slight temperature increase, while a complete shutdown of the forced oil cooling system will trigger a sharp temperature spike across the transformer. This scope assessment helps narrow down potential causes, such as localized electrical failures or a global control circuit issue.

- Inspect Electrical, Mechanical, and Control Circuit Components

- Electrical Checks: Verify the power supply to cooling units, check for blown fuses, tripped circuit breakers, and damaged wiring connections. Use a multimeter to test the voltage and current supplied to fans and pumps to ensure they meet operational requirements.

- Mechanical Checks: Examine fan blades and pump impellers for physical damage, blockages, or bearing wear. Rotate components manually (after power isolation) to check for jamming or excessive friction.

- Control Circuit Checks: Inspect the temperature sensors, control relays, and PLC (Programmable Logic Controller) modules that regulate cooling system operation. Ensure that sensor readings are accurate and that control signals are being transmitted correctly.

Safe Restoration and Operational Adjustments

Gradual Startup of Cooling Units

When restoring power to the cooling system, start the units in a step-by-step manner rather than all at once. This approach prevents sudden changes in coolant flow and pressure, which could damage pipeline joints or cause sensor misalignment. For forced oil cooling systems, start the oil pumps first, followed by the cooling fans after the oil circulation is stabilized.

Load Reduction for Unrepairable Faults

In cases where the cooling device fault cannot be repaired quickly (e.g., due to a lack of replacement parts), the transformer must be operated at a reduced load. The load reduction ratio should be determined based on the remaining cooling capacity and the transformer’s temperature rise curve. This temporary measure allows the transformer to continue operating for a limited period while waiting for permanent repairs.

Abnormal Oil Level: A Critical Power Transformer Fault with Multiple Manifestations

Key Types of Oil Level Anomalies: Causes and Solutions

| Oil Level Anomaly Type | Primary Causes | Troubleshooting and Resolution Steps | Preventive Measures |

|---|---|---|---|

| Low Oil Level | Severe oil leakage from gaskets, valves, or pipeline joints; oil degradation leading to volume reduction; improper oil filling during maintenance | 1. Locate the leak source via visual inspection and pressure testing 2. Add qualified insulating oil to restore the level to the normal range 3. If leakage is severe and cannot be stopped temporarily, shut down the transformer immediately for repair | Regularly inspect sealing components for wear; conduct annual oil quality testing; monitor oil level trends via automated sensors |

| High Oil Level | Overfilling during maintenance; excessive load leading to oil expansion; blocked oil conservator breathing valve; cooling system failure causing oil temperature rise | 1. Check real-time load and cooling system status to rule out thermal expansion causes 2. Inspect the breathing valve and release accumulated air if blocked 3. Drain excess oil gradually to bring the level back to the optimal range 4. If the oil level of the tap changer rises abnormally (or oil overflows), investigate the main tank oil infiltration and shut down for repair if confirmed | Follow oil filling specifications strictly; clean breathing valve filters regularly; monitor tap changer oil level independently |

| Inaccurate Oil Level Indication | Air accumulation in the oil conservator air bag; clogged breathing system preventing pressure equalization; rupture of the oil conservator capsule; damaged level gauge float or sensor | 1. Bleed accumulated air from the air bag or oil conservator 2. Inspect the breathing valve and pipeline for blockages and clear obstructions 3. Check the oil conservator capsule for tears or leaks; replace if damaged 4. Calibrate or replace faulty level gauges and sensors | Conduct quarterly inspections of the oil conservator and breathing system; test level gauge accuracy during routine maintenance |

Hidden Risks of Ignoring Oil Level Anomalies

- Low oil levels expose internal windings and core to air, accelerating insulation aging and increasing the risk of partial discharge.

- High oil levels cause excessive pressure inside the transformer, leading to oil leakage through seals or even damage to the oil conservator.

- Inaccurate oil level indications can mislead maintenance personnel, resulting in delayed response to actual oil level issues and increased fault risks.

Light Gas Relay Activation: Interpreting a Common Power Transformer Fault Signal

Standard Response Protocol for Light Gas Relay Action

Comprehensive On-Site Visual and Operational Inspection

Conduct a thorough check of the transformer’s external condition and operational parameters, including:

- External appearance: Look for oil leaks, damage to bushings or cooling units, and signs of overheating.

- Audible sounds: Listen for unusual humming, buzzing, or bubbling noises that indicate internal component issues.

- Temperature distribution: Use infrared thermography to check for localized hot spots on the transformer tank and bushings.

- Oil level status: Verify that the oil level is within the normal range to rule out level-related false alarms.

- Real-time load: Confirm that the transformer is not operating beyond its rated capacity, as excessive load can generate gas due to mild overheating.

Gas Analysis: The Key to Identifying Fault Nature

The most critical step in diagnosing light gas relay activation is collecting and analyzing the gas trapped in the relay chamber. This analysis can be divided into two primary tests:

- Flammability Test: Use a flame source (in a safe, well-ventilated area) to check if the gas is flammable. Flammable gas typically indicates internal faults such as winding insulation degradation, core overheating, or tap changer contact arcing.

- Gas Chromatography Analysis: For a more accurate diagnosis, send gas samples to a laboratory for chromatographic testing. This test identifies the types and concentrations of gases present, allowing technicians to pinpoint the exact fault type (e.g., partial discharge, thermal decomposition, or arcing).

Differentiating Between Fault Alarms and False Alarms

Not all light gas relay activations indicate actual transformer faults. False alarms can be caused by factors such as air ingress into the oil during maintenance, temperature fluctuations leading to oil degassing, or secondary circuit malfunctions (e.g., loose wiring, faulty relays). If the gas analysis confirms that the trapped gas is air and no other abnormal symptoms are detected, the maintenance team should inspect the secondary circuit for potential issues and reset the relay. However, if flammable gas or abnormal chromatographic results are found, the transformer must be shut down immediately for in-depth inspection and repair.

Transformer Tripping: A Protective Response to Severe Power Transformer Faults

Systematic Post-Tripping Analysis Process

Identify the Type of Protection Action Triggered

First, retrieve the protection system’s operation records to determine which protective relays were activated. Common protective functions include differential protection, overcurrent protection, gas protection, and over-temperature protection. For example, the simultaneous activation of differential protection and gas protection strongly suggests a severe internal fault, while overcurrent protection activation may indicate an external short circuit in the power grid.

Analyze Fault Recording Data

Modern transformer protection systems are equipped with fault recorders that capture voltage, current, and temperature data before, during, and after the tripping event. Analyzing this data helps determine the fault’s duration, magnitude, and development trend. For instance, a sudden spike in short-circuit current indicates an external fault, while a gradual increase in winding temperature before tripping points to an internal overheating issue.

Conduct a Comprehensive External Inspection

After isolating the transformer from the power grid, perform a detailed visual inspection of the unit to look for visible signs of faults:

- Check for oil spraying or leakage on the transformer tank, conservator, and bushings.

- Inspect bushings for signs of flashover, such as carbonization marks or cracked insulators.

- Verify the status of gas relays to see if they have accumulated excessive gas or triggered heavy gas protection.

- Look for signs of deformation or bulging on the transformer tank, which indicate internal pressure buildup.

Clear Criteria for Restart or Shutdown Inspection

- Conditions for Safe Restart: If the tripping was caused by non-main body factors (e.g., external grid short circuits, transient voltage surges, or protective relay malfunctions) and no visible faults or abnormal data are detected, the transformer can be restarted after proper testing.

- Conditions for Mandatory Shutdown Inspection: A full shutdown and internal inspection are required if any of the following signs are present: visible internal fault symptoms (tank deformation, oil spraying), activation of two or more main protection systems, detection of flammable gas in gas relays, or abnormal chromatographic analysis results of oil samples.

Abnormal Noises: Audible Clues to Underlying Power Transformer Faults

Classification of Abnormal Noises, Fault Correlations, and Response Actions

| Abnormal Noise Type | Description of Sound | Corresponding Potential Faults | Immediate Response Actions |

|---|---|---|---|

| Noisy Vibration | Loud, irregular humming that replaces the steady normal hum; vibration can be felt on the transformer tank | Loose core laminations, damaged core insulation, loose clamping bolts of core or windings | Shut down the transformer immediately for inspection; tighten loose components and repair damaged core insulation before restarting |

| Gurgling Bubble Sound | Continuous or intermittent gurgling sounds coming from inside the transformer tank | Severe faults in windings or tap changers, such as insulation breakdown, arcing, or localized overheating that causes oil decomposition and gas generation | Stop transformer operation right away; conduct oil chromatography and internal inspection to locate and repair the fault |

| Explosion-Like Sound | Suddenly, loud bangs or popping sounds | Severe insulation breakdown between windings or between windings and ground; internal short circuits that generate high-temperature arcs | Trigger emergency shutdown procedures immediately; isolate the transformer from the grid and prevent personnel from approaching the unit due to explosion risks |

| Squeaky Discharge Sound | High-pitched, continuous squeaking or crackling sounds | Corona discharge or surface discharge on bushings, insulator surfaces, or internal components, caused by contamination, moisture ingress, or insulation degradation | Clean contaminated bushings and insulators first; if the sound persists after cleaning, shut down the transformer for a full inspection of internal insulation |

| Regular Impact/Friction Sound | Periodic thumping or scraping sounds at fixed intervals | Loose mechanical components (e.g., fan blades, pump impellers), loose clamping parts, or electrostatic discharge between components | Isolate the power supply and inspect mechanical components for looseness or damage; tighten or replace faulty parts; test for electrostatic discharge if mechanical issues are ruled out |

Key Notes on Noise-Based Fault Diagnosis

- Conduct noise inspections in a quiet environment to distinguish between transformer noises and background sounds from surrounding equipment.

- Use a stethoscope to listen to different parts of the transformer tank (e.g., core area, winding area, tap changer area) to pinpoint the noise source.

- Combine noise analysis with other diagnostic methods (temperature measurement, oil analysis) to confirm fault types, as some noises may have multiple potential causes.

Oil Spraying and Explosion: Extreme Consequences of Unresolved Power Transformer Faults

Root Causes and Development Process of Oil Spraying and Explosion

- Initial Fault Onset: Internal faults such as winding insulation damage, internal arc discharge, or tap changer failures occur, but their symptoms are mild or ignored.

- Oil Decomposition and Gas Generation: The fault generates high temperatures that cause the insulating oil to decompose rapidly, producing a large volume of flammable gases (hydrogen, methane, ethylene, etc.).

- Internal Pressure Surge: As gases accumulate rapidly inside the sealed transformer tank, the internal pressure rises sharply beyond the tank’s pressure-bearing capacity.

- Oil Spraying and Explosion: The high pressure forces the insulating oil to spray out from the weakest points of the tank (e.g., weld seams, flange connections, or pressure relief valves). If the oil comes into contact with an ignition source (e.g., high-temperature components, electric arcs), it will ignite, leading to a full-scale transformer explosion.

Critical Importance of Rapid Fault Isolation

- Install and maintain reliable protection systems (gas protection, differential protection, over-temperature protection) to ensure timely detection and tripping of faulty transformers.

- Conduct regular oil chromatography testing and infrared temperature scanning to identify hidden internal faults at an early stage.

- Establish a rapid response mechanism for fault alarms, ensuring that maintenance personnel can reach the site and take isolation measures within the shortest possible time.

Emergency Shutdown Conditions for Power Transformers: Non-Negotiable Safety Protocols

Significant Increase or Abnormality in Internal Noises

If the transformer’s internal noise changes from the normal steady hum to loud, irregular sounds such as explosions, bangs, or gurgling, it indicates severe internal faults (e.g., insulation breakdown, winding short circuits). Continuing to operate the unit will lead to rapid fault escalation.

Severe Damage or Discharge of Bushings and Insulators

Bushings and insulators are critical components that ensure electrical insulation between the transformer and the external grid. If any of these components show signs of severe damage (cracks, breakage, or carbonization marks) or sustained discharge (corona, flashover), immediate shutdown is required to prevent short circuits and power grid failures.

Smoke Emission, Fire, or Oil Spraying

The emergence of smoke from the transformer tank, visible fire on any part of the unit, or oil spraying from the tank or conservator are clear signs of critical faults. These symptoms indicate that the transformer is at high risk of explosion, and personnel must evacuate the area immediately after initiating the emergency shutdown procedure.

Protection Device Refusal to Operate or Malfunction

The protection system is the transformer’s last line of defense against faults. If the protection relays fail to activate when obvious fault symptoms are present (refusal to operate) or activate repeatedly without any detectable faults (malfunction), the transformer must be shut down. Operating a transformer without reliable protection is extremely dangerous.

Nearby Fire or Explosion Threatening Transformer Safety

If a fire or explosion occurs in adjacent equipment or facilities and poses a direct threat to the transformer (e.g., the fire is spreading toward the unit, or toxic/flammable gases are accumulating around it), the transformer should be shut down immediately to prevent secondary accidents.