If you’re involved in power system planning, transformer procurement, or maintenance, you likely have questions: What exactly are power transformer losses? What causes them? How do they affect transformer performance and overall energy efficiency? And most importantly, what practical measures can be taken to minimize these losses? This comprehensive guide will address all these key questions, providing authoritative insights into power transformer losses to help you make informed decisions for your power system.

Power Transformer Losses: Definition and Core Significance in Power Systems

Before delving into the specifics of power transformer losses, it’s essential to clarify their basic definition and why they matter in the broader context of power systems. Power transformer losses refer to the energy that is converted into heat and dissipated during the transformer’s normal operation, rather than being transmitted as useful electrical energy. Unlike the intended voltage conversion function, these losses are unintended but unavoidable to some extent—yet their magnitude can be significantly influenced by design choices, material quality, and operational practices.

The significance of power transformer losses extends far beyond mere energy waste. In large-scale power grids, where hundreds or thousands of transformers operate continuously, cumulative losses translate to massive energy inefficiencies. For utility companies, this means higher fuel consumption (for thermal power plants) or underutilized renewable energy potential, directly leading to increased electricity costs for end-users. From an environmental perspective, elevated energy consumption associated with losses results in higher carbon dioxide (CO₂) and other greenhouse gas emissions, conflicting with global sustainability goals.

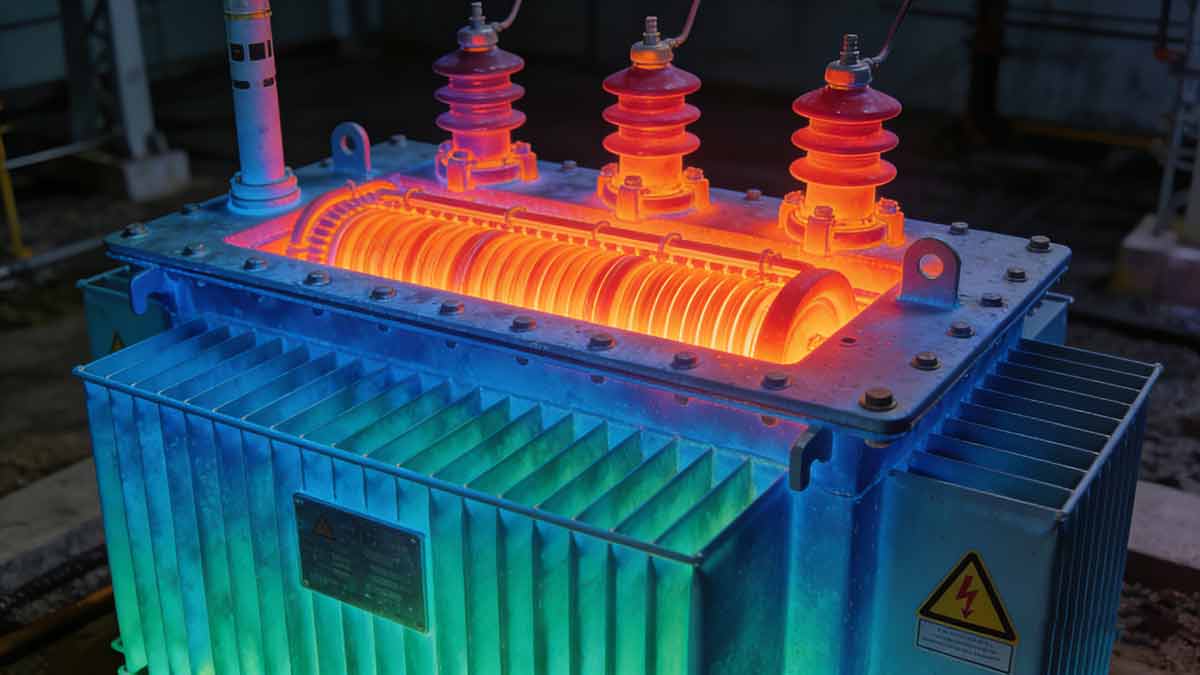

Additionally, the heat generated by these losses raises the internal temperature of the transformer. Transformers rely on insulation materials to prevent short circuits and ensure safe operation, but prolonged exposure to high temperatures degrades insulation performance over time. This not only reduces the transformer’s lifespan—potentially leading to premature failure—but also increases the risk of unplanned outages, which can have severe consequences for industrial production, commercial operations, and residential comfort. For transformer manufacturers and operators, understanding and mitigating power transformer losses is therefore a critical aspect of ensuring system reliability, cost-effectiveness, and environmental compliance.

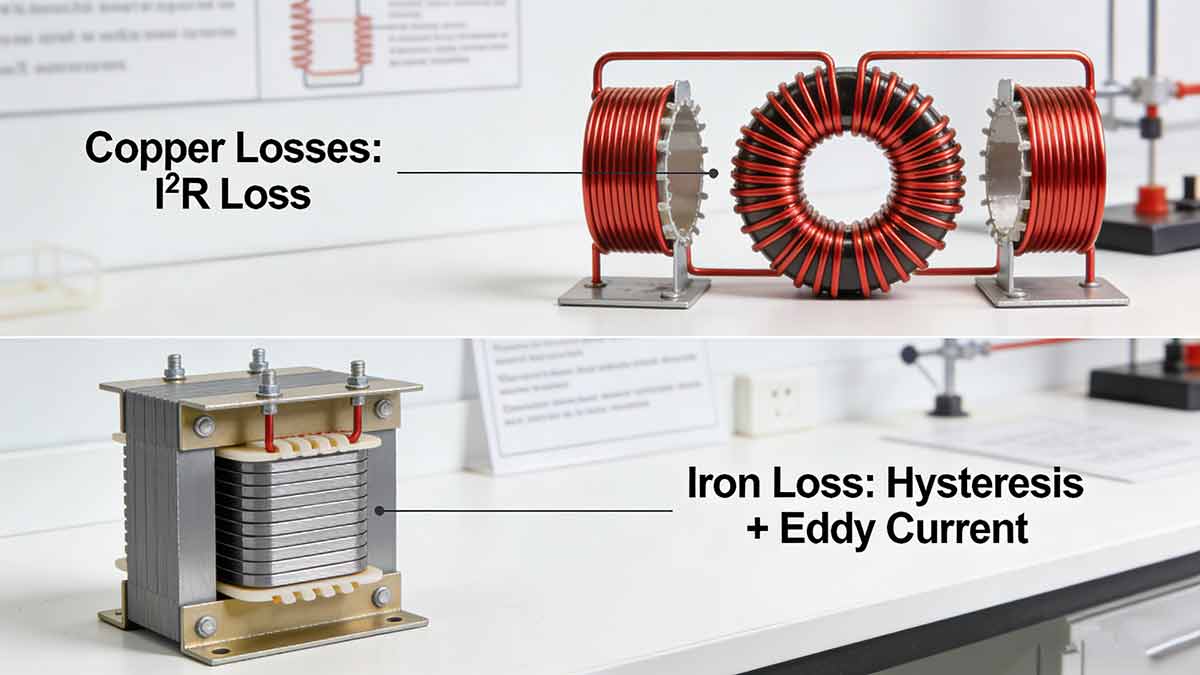

Types of Power Transformer Losses: Copper Losses and Iron Losses Explained

Power transformer losses are primarily categorized into two distinct types: copper losses (also known as ohmic losses) and iron losses (also referred to as core losses). Each type arises from different physical phenomena within the transformer, is influenced by different factors, and requires targeted strategies to mitigate. Below is a detailed breakdown of each loss type, including its causes, influencing factors, and real-world implications.

Copper Losses in Power Transformers: Causes and Influencing Factors

Copper losses occur due to the electrical resistance of the transformer’s windings, which are typically made of copper (though aluminum is sometimes used in lower-cost designs). When an electric current flows through these windings, the resistance of the conductor opposes the current flow, converting a portion of the electrical energy into heat. This is a direct application of Joule’s Law, which states that the power lost as heat (P) is proportional to the square of the current (I) and the resistance (R) of the conductor (P = I²R).

A key characteristic of copper losses is that they are load-dependent—meaning they increase as the transformer’s load (and thus the current flowing through the windings) increases. At no load (when the transformer is energized but no current is drawn from the secondary winding), copper losses are nearly negligible because the current is extremely small. However, at full load, when the maximum rated current flows through the windings, copper losses reach their peak.

Several factors influence the magnitude of copper losses:

1. Conductor Material and Cross-Sectional Area: Copper has a lower electrical resistance than aluminum, so copper windings result in lower copper losses. Additionally, increasing the cross-sectional area of the conductor reduces its resistance (since resistance is inversely proportional to the cross-sectional area of the conductor). This is why high-efficiency transformers often use larger-gauge copper windings.

2. Winding Design: The way the windings are wound can also affect resistance. For example, windings with more turns will have longer conductor lengths, increasing resistance and thus copper losses. Optimized winding designs—such as using concentric windings for low-voltage transformers or disc windings for high-voltage applications—can help minimize conductor length and resistance.

3. Operating Temperature: The resistance of copper increases with temperature. As the transformer operates and generates heat, the resistance of the windings rises, leading to a slight increase in copper losses. This is why proper cooling of the transformer is not only important for insulation life but also for minimizing copper losses during extended operation.

Iron Losses in Power Transformers: Hysteresis and Eddy Current Losses

Unlike copper losses, iron losses are load-independent—they occur whenever the transformer is energized, regardless of whether it is supplying power to a load. Iron losses arise from the magnetization and demagnetization of the transformer’s core, which is typically made of ferromagnetic materials such as silicon steel. These losses are further divided into two subcategories: hysteresis losses and eddy current losses.

Hysteresis Losses

Hysteresis losses occur due to the magnetic hysteresis of the core material. When the alternating current (AC) supply energizes the transformer, the magnetic field in the core alternates direction (magnetization and demagnetization) at the frequency of the supply (e.g., 50 Hz or 60 Hz). Each time the magnetic field reverses, the core material requires energy to reorient its magnetic domains, and some of this energy is dissipated as heat. The magnitude of hysteresis losses depends on the properties of the core material—specifically, its hysteresis loop area. Materials with smaller hysteresis loops (such as high-grade silicon steel or amorphous alloys) have lower hysteresis losses.

Eddy Current Losses

Eddy current losses are caused by eddy currents induced in the core material. The alternating magnetic field in the core induces small electric currents (eddy currents) that circulate within the core, opposing the magnetic field changes (per Lenz’s Law). These circulating currents flow through the core’s resistance, generating heat. The magnitude of eddy current losses is proportional to the square of the core thickness, the square of the supply frequency, and the magnetic flux density.

To minimize eddy current losses, transformer cores are constructed using thin, insulated laminations (typically 0.25–0.35 mm thick) instead of a solid block of ferromagnetic material. The insulation between laminations breaks up the path of eddy currents, limiting their circulation and thus reducing the associated losses. High-efficiency transformers may use even thinner laminations or coatings to further reduce eddy current losses.

How to Measure Power Transformer Losses: Authoritative Test Methods

Accurately measuring power transformer losses is critical for assessing transformer efficiency, verifying compliance with industry standards (such as IEEE C57.12.00 or IEC 60076), and identifying potential issues during operation. The two primary tests used to measure power transformer losses are the no-load test (also known as the open-circuit test) and the load test (also known as the short-circuit test). Below is a detailed explanation of each test, including its purpose, procedure, and how it contributes to calculating total losses.

No-Load Test for Power Transformer Losses: Measuring Iron Losses

The no-load test is designed to measure iron losses (hysteresis and eddy current losses) and the magnetizing current of the transformer. As the name suggests, the test is performed when the transformer’s secondary winding is open-circuited (no load connected), and the primary winding is supplied with the rated voltage at the rated frequency.

Test Procedure:

1. Disconnect the transformer from the main power system to ensure safety and accurate measurements.

2. Open-circuit the secondary winding (remove all load connections).

3. Connect the primary winding to a variable AC power supply capable of delivering the transformer’s rated voltage and frequency.

4. Gradually increase the supply voltage to the rated value, ensuring the frequency remains constant.

5. Measure the input power (using a wattmeter), input voltage, and input current (magnetizing current) to the primary winding.

During the no-load test, the primary current is very small (typically 2–5% of the rated primary current) because there is no load current in the secondary. As a result, copper losses in the primary winding are negligible (since copper losses are proportional to the square of the current). The measured input power during the no-load test is therefore almost entirely composed of iron losses. This makes the no-load test the standard method for determining iron losses in power transformers.

Key Considerations: The no-load test must be performed at the rated voltage and frequency because iron losses are dependent on both factors. If the supply voltage is higher than the rated value, iron losses will increase (since they are proportional to the square of the voltage), leading to inaccurate measurements. Similarly, a change in frequency will affect the magnetization characteristics of the core, altering the magnitude of iron losses.

Load Test for Power Transformer Losses: Measuring Copper Losses

The load test (short-circuit test) is used to measure copper losses and the impedance voltage of the transformer. Unlike the no-load test, the load test is performed with the secondary winding short-circuited, and the primary winding is supplied with a reduced voltage (typically 5–10% of the rated voltage) to achieve the rated current in the windings.

Test Procedure:

1. Ensure the transformer is disconnected from the main power system.

2. Short-circuit the secondary winding using a low-resistance conductor (to simulate a full-load current).

3. Connect the primary winding to a variable AC power supply.

4. Gradually increase the supply voltage until the primary current reaches the rated value (or the secondary current reaches its rated value, as measured by an ammeter).

5. Measure the input power (using a wattmeter), input voltage, and input current.

During the load test, the supply voltage is much lower than the rated voltage, so the magnetic flux density in the core is very small. This results in negligible iron losses (since iron losses depend on the square of the voltage). The measured input power during the load test is therefore almost entirely composed of copper losses (in both the primary and secondary windings) at rated load.

To calculate copper losses at different load levels (e.g., half load, 75% load), the following formula is used: Copper Loss at x Load = Copper Loss at Full Load × (x)². This is because copper losses are proportional to the square of the current, and the current at x load is x times the rated current. For example, copper losses at half load (x = 0.5) will be 25% of the full-load copper losses.

Key Considerations: The load test must be performed at the rated current to ensure accurate measurement of full-load copper losses. Additionally, the short-circuit connection must be low-resistance to avoid introducing additional losses into the measurement.

Calculating Total Power Transformer Losses

Total power transformer losses are the sum of iron losses (measured via the no-load test) and copper losses (measured via the load test) at a given load level. Mathematically, this is expressed as:

Total Losses = Iron Losses + Copper Losses at x Load

Since iron losses are load-independent, they remain constant regardless of the load level. Copper losses, however, vary with the square of the load current, as discussed earlier. This relationship is critical for understanding transformer efficiency at different operating conditions—for example, a transformer operating at half load will have lower total losses than one operating at full load, but its efficiency may be lower or higher depending on the balance between iron and copper losses.

Impacts of Power Transformer Losses on Efficiency, Cost, and Lifespan

Power transformer losses have far-reaching impacts on the performance, economics, and longevity of transformers and power systems. Understanding these impacts is essential for justifying investments in high-efficiency transformers or maintenance practices aimed at reducing losses. Below are the key impacts of power transformer losses:

Reduced Transformer Efficiency and Higher Energy Costs

Transformer efficiency is defined as the ratio of useful output power to input power, expressed as a percentage: Efficiency (%) = (Output Power / Input Power) × 100. Since Input Power = Output Power + Total Losses, any increase in total losses directly reduces efficiency. For example, a transformer with total losses of 10 kW at full load and an output power of 990 kW has an efficiency of 99% (990 / 1000 × 100). If losses increase to 20 kW, the efficiency drops to 98.04% (990 / 1010 × 100).

While a 1% reduction in efficiency may seem small, the cumulative effect over time and across multiple transformers is significant. For a utility company operating hundreds of transformers, each with a 1% efficiency gap, the annual energy waste can amount to millions of kilowatt-hours (kWh), translating to higher fuel costs and increased electricity prices for consumers. For industrial facilities with large transformers (e.g., 10 MVA or higher), even a 0.5% reduction in efficiency can add tens of thousands of dollars to annual energy bills.

Increased Carbon Emissions and Environmental Impact

The energy wasted as power transformer losses must be compensated for by additional power generation. For thermal power plants (which burn coal, natural gas, or oil), this means increased fuel consumption and higher emissions of CO₂, sulfur dioxide (SO₂), and nitrogen oxides (NOₓ)—all of which contribute to climate change and air pollution. For example, a coal-fired power plant emits approximately 0.9 kg of CO₂ per kWh of electricity generated. A transformer that wastes 10,000 kWh annually due to losses therefore contributes an additional 9,000 kg of CO₂ to the atmosphere each year.

In an era of increasing focus on sustainability and carbon neutrality, reducing power transformer losses is a critical step for power companies and industrial facilities to meet environmental regulations and sustainability goals. High-efficiency transformers, which minimize losses, are therefore becoming a mandatory requirement in many regions (e.g., the European Union’s Ecodesign Directive for transformers).

Thermal Degradation and Reduced Transformer Lifespan

As mentioned earlier, power transformer losses generate heat, which raises the internal temperature of the transformer. Transformer insulation materials (such as paper, oil, and varnish) are designed to operate within a specific temperature range—typically up to 105°C for standard transformers. Prolonged exposure to temperatures above this range accelerates insulation degradation, reducing its dielectric strength and increasing the risk of short circuits or insulation breakdown.

The lifespan of a transformer is closely linked to the temperature of its windings. Industry studies have shown that for every 6°C increase in winding temperature above the rated limit, the lifespan of the insulation is halved (this is known as the Arrhenius Law). For example, a transformer with a rated winding temperature of 105°C and an expected lifespan of 25 years will have its lifespan reduced to 12.5 years if the average winding temperature increases to 111°C due to excessive losses. Premature transformer failure not only results in costly replacement expenses but also causes unplanned outages, which can disrupt industrial production, commercial operations, and residential power supply.

Increased Maintenance Costs

Excessive power transformer losses and the associated heat generation also increase maintenance costs. High temperatures can cause transformer oil to degrade more quickly, requiring more frequent oil testing and replacement. Additionally, thermal expansion and contraction of transformer components (due to temperature fluctuations from varying losses) can lead to mechanical stress, loosening of connections, and increased wear on parts such as bushings and tap changers. Regular maintenance to address these issues—such as oil filtration, connection tightening, and component inspections—adds to the operational costs of the transformer.

Practical Strategies to Reduce Power Transformer Losses: Authoritative Solutions

Given the significant impacts of power transformer losses, implementing strategies to minimize them is a worthwhile investment for power system operators, industrial facilities, and transformer manufacturers. The following are authoritative, practical solutions to reduce power transformer losses, organized by design, material selection, operational practices, and maintenance.

Optimize Transformer Design to Minimize Losses

The design of a transformer plays a critical role in determining its loss characteristics. Transformer manufacturers can optimize several design parameters to reduce both copper and iron losses:

1. Winding Design Optimization: As discussed earlier, increasing the cross-sectional area of copper windings reduces resistance and thus copper losses. Manufacturers can also optimize the number of winding turns to balance copper losses and voltage regulation. For example, using a lower number of turns (with larger conductors) can reduce copper losses, but it may increase magnetic flux density in the core (leading to higher iron losses). A balanced design is therefore essential.

2. Core Design Optimization: The core design directly impacts iron losses. Using a core with a larger cross-sectional area reduces magnetic flux density, which in turn reduces hysteresis and eddy current losses. Additionally, optimizing the core shape (e.g., using a stepped core design) reduces the length of the magnetic path, minimizing magnetization losses.

3. Cooling System Design: Efficient cooling systems help maintain lower winding and core temperatures, reducing copper losses (since resistance increases with temperature) and extending insulation life. Common cooling systems for transformers include natural oil cooling (ONAN), forced oil cooling (OFAF), and forced air cooling (ONAF). For high-power transformers or those operating in high-temperature environments, advanced cooling systems (such as oil-immersed, water-cooled systems) can be used to further reduce operating temperatures.

Select High-Quality Materials to Reduce Losses

The choice of materials used in transformer construction has a direct impact on loss levels. Investing in high-quality materials can significantly reduce both copper and iron losses:

1. High-Conductivity Winding Materials: Using high-purity copper for windings (instead of aluminum or lower-grade copper) reduces resistance, minimizing copper losses. Copper has a conductivity of 58 MS/m, compared to 37 MS/m for aluminum, making it a superior choice for low-loss transformers.

2. Low-Loss Core Materials: The use of high-grade ferromagnetic materials for the core is critical for reducing iron losses. Silicon steel (also known as electrical steel) is the most common core material, with high-grade silicon steel (containing 3–4% silicon) offering lower hysteresis and eddy current losses than standard steel. Amorphous metal cores (made of non-crystalline alloys such as iron-boron-silicon) are even more efficient, with iron losses up to 70% lower than traditional silicon steel cores. While amorphous cores are more expensive, they are an excellent choice for high-efficiency transformers in applications where energy savings justify the higher upfront cost.

3. High-Quality Insulation Materials: Using high-temperature insulation materials (such as Nomex or epoxy resin) allows the transformer to operate at higher temperatures without accelerating insulation degradation. This can enable the use of more compact designs (with smaller windings or cores) that have lower losses, as the insulation can withstand the higher heat generated by the optimized design.

Implement Efficient Operational Practices

Even with a well-designed, high-quality transformer, operational practices can significantly influence loss levels. The following operational strategies can help minimize power transformer losses:

1. Operate Transformers at Optimal Load Levels: Transformers are most efficient at a specific load level—typically 50–75% of full load. At this load range, the balance between iron losses (constant) and copper losses (load-dependent) is optimized, resulting in maximum efficiency. Operating a transformer at very low load (e.g., below 25% of full load) means that iron losses constitute a large portion of total losses, reducing efficiency.

Conversely, operating at above full load increases copper losses exponentially, leading to a sharp drop in efficiency and increased heat generation. Power system operators should therefore monitor transformer load levels and redistribute loads between transformers to ensure each operates at or near its optimal load.

2. Avoid Overvoltage Conditions: Since iron losses are proportional to the square of the supply voltage, operating the transformer at voltages above its rated value significantly increases iron losses. Power system operators should ensure that the supply voltage to transformers remains within the rated range (typically ±5% of the rated voltage) to minimize iron losses.

3. Use On-Load Tap Changers (OLTCs) for Voltage Regulation: OLTCs allow transformers to adjust their turns ratio and thus voltage levels without disconnecting from the power system. By maintaining the output voltage at the optimal level, OLTCs help reduce losses associated with voltage fluctuations. Additionally, OLTCs can be used to balance loads between parallel transformers, ensuring each operates at optimal efficiency.

Regular Maintenance and Monitoring to Mitigate Losses

Regular maintenance and monitoring of transformers are essential for detecting and addressing issues that can increase losses over time. The following maintenance practices can help minimize power transformer losses:

1. Regular Loss Testing: Conducting periodic no-load and load tests (as discussed earlier) allows operators to monitor changes in loss levels over time. An increase in losses may indicate issues such as winding damage (increased resistance), core degradation, or oil contamination. Early detection of these issues enables timely repairs, preventing further loss increases and potential transformer failure.

2. Transformer Oil Maintenance: Transformer oil serves as both an insulator and a cooling medium. Over time, oil can become contaminated with moisture, dirt, and oxidation products, reducing its dielectric strength and cooling efficiency. Regular oil testing (for parameters such as breakdown voltage, moisture content, and acidity) and filtration or replacement of contaminated oil help maintain efficient cooling, reducing losses associated with high temperatures.

3. Cleaning and Inspection of Cooling Systems: Clogged or dirty cooling systems (such as radiators or fans) reduce cooling efficiency, leading to higher operating temperatures and increased losses. Regular cleaning of radiators, inspection of fans, and replacement of faulty cooling components ensure that the transformer remains at optimal operating temperature.

4. Tightening of Electrical Connections: Loose connections in the transformer’s windings or terminals can increase resistance, leading to additional copper losses and localized heating. Regular inspection and tightening of connections (using torque wrenches to ensure proper tension) helps maintain low resistance and minimize losses.

FAQ About Power Transformer Losses

To further address customer doubts about power transformer losses, below are answers to some of the most commonly asked questions, provided with authoritative insights based on industry standards and best practices.

Q1: Are power transformer losses completely avoidable?

A1: No, power transformer losses are not completely avoidable. They are inherent to the physical processes of voltage conversion (magnetization of the core and current flow through windings). However, their magnitude can be significantly reduced through optimized design, high-quality materials, efficient operation, and regular maintenance. Modern high-efficiency transformers can achieve losses that are 50–70% lower than standard transformers, making them a cost-effective solution for minimizing energy waste.

Q2: How do power transformer losses differ between dry-type and oil-immersed transformers?

A2: The basic types of losses (copper and iron losses) are the same for both dry-type and oil-immersed transformers. However, the magnitude of losses can differ due to design and material differences. Oil-immersed transformers typically use liquid cooling, which is more efficient than the air cooling used in most dry-type transformers. This allows oil-immersed transformers to use more compact windings and cores, potentially reducing copper and iron losses. Additionally, oil-immersed transformers often use higher-grade core materials (such as amorphous metal) for lower iron losses. Dry-type transformers, on the other hand, may have slightly higher losses due to less efficient cooling, but they are preferred in applications where fire safety is a priority (e.g., indoor industrial facilities or commercial buildings).

Q3: What is the difference between no-load losses and load losses in power transformers?

A3: No-load losses (also known as iron losses) are load-independent and occur whenever the transformer is energized. They include hysteresis and eddy current losses in the core. Load losses (also known as copper losses) are load-dependent and occur due to the resistance of the windings when current flows through them. No-load losses are measured via the no-load test (open-circuit test), while load losses are measured via the load test (short-circuit test). Total transformer losses are the sum of no-load losses and load losses at a given load level.

Q4: How do power transformer losses affect the choice of transformer for a specific application?

A4: The choice of transformer for a specific application should take into account the expected load profile and the cost of energy. For applications with continuous full-load operation (e.g., industrial plants with constant power demand), high-efficiency transformers with low copper and iron losses are ideal, as the energy savings will quickly offset the higher upfront cost. For applications with variable or low load (e.g., residential neighborhoods with peak demand only during certain hours), transformers with lower iron losses (even if copper losses are slightly higher) may be more cost-effective, as iron losses are constant regardless of load. Additionally, applications in regions with strict environmental regulations may require high-efficiency transformers to meet carbon emission targets.

Q5: Can retrofitting existing transformers reduce power transformer losses?

A5: Yes, retrofitting existing transformers can be a cost-effective way to reduce losses without replacing the entire transformer. Common retrofitting measures include: (1) Replacing the core with a low-loss core material (such as amorphous metal); (2) Rewinding the windings with larger-gauge copper conductors; (3) Upgrading the cooling system to improve heat dissipation; (4) Installing OLTCs for better voltage regulation and load balancing. The feasibility and cost-effectiveness of retrofitting depend on the age and condition of the existing transformer. For older transformers with significant insulation degradation, replacement with a new high-efficiency transformer may be a better long-term solution.

Conclusion: The Importance of Addressing Power Transformer Losses for Sustainable and Efficient Power Systems

Power transformer losses are a critical consideration in the design, operation, and maintenance of power systems. They affect not only the efficiency and cost of electricity transmission and distribution but also the environmental impact and lifespan of transformer equipment. By understanding the types of losses (copper and iron losses), their causes, and their impacts, power system operators, industrial facilities, and transformer manufacturers can implement targeted strategies to minimize losses—including optimized design, high-quality material selection, efficient operational practices, and regular maintenance.

In an era of increasing energy costs and growing focus on sustainability, investing in measures to reduce power transformer losses is not only a financial decision but also an environmental responsibility. High-efficiency transformers, which minimize losses, not only reduce energy bills and carbon emissions but also improve the reliability and lifespan of power systems, ensuring a stable and sustainable supply of electricity for years to come. Whether you’re procuring a new transformer, maintaining existing equipment, or optimizing your power system, addressing power transformer losses is a key step toward achieving greater efficiency, cost savings, and environmental compliance.