Advantages of Power Distribution Transformer

- Prolonged Service Life

Hermetic sealing protects internal components from moisture and contaminants, extending service life by over 30% compared to open-type models.

- Reduced Maintenance Requirements

The sealed design eliminates the need for regular moisture testing and contaminant cleaning, reducing maintenance workload by 50%.

- Enhanced Operational Reliability

Reduced exposure to external environmental factors significantly lowers the risk of failure in critical applications such as power grids and industrial plants.

- Environmental Benefits

It prevents soil and water pollution caused by oil leaks, complying with the EPA’s standards for eco-friendly operation.

| S11 33kV Oil-immersed Power Distribution Transformer | |||||||

Rated Capacity(kVA) | Voltage combinations | Connection Method | No-load loss (W) | Load loss (W) | No-load current (%) | Short-circuit impedance | |

| HV(kV) | LV(kV) | ||||||

| 50 | 33 35 38.5 | 0.4 0.416 0.420 0.440 | Dyn11 or Yyn0 | 210 | 1270/1210 | 2 | 6.5 |

| 100 | 290 | 2120/2020 | 1.8 | ||||

| 150 | 340 | 2500/2380 | 1.7 | ||||

| 160 | 360 | 2970/2380 | 1.6 | ||||

| 200 | 430 | 3500/3330 | 1.5 | ||||

| 250 | 510 | 4160/3960 | 1.4 | ||||

| 300 | 610 | 5010/4770 | 1.4 | ||||

| 400 | 730 | 5050/5760 | 1.3 | ||||

| 500 | 860 | 7280/6930 | 1.2 | ||||

| 600 | 1040 | 8280 | 1.1 | ||||

| 750 | 1230 | 9900 | 1 | ||||

| 1000 | 1440 | 12150 | 1 | ||||

| 1250 | 1760 | 14670 | 0.9 | ||||

| 1500 | 2120 | 17550 | 0.8 | ||||

| 2000 | 2490 | 20740 | 0.8 | ||||

| 2500 | 2950 | 24420 | 0.8 | ||||

| 3000 | 3510 | 29050 | 0.7 | ||||

| 4000 | 4200 | 34940 | 0.7 | ||||

Oil – Immersed Power Distribution Transformer: The Backbone of Efficient Power Distribution

In the complex web of electrical systems, the oil-immersed power distribution transformer plays a pivotal role. As a key component in power distribution networks, it ensures that electricity is transmitted and converted reliably, powering homes, industries, and communities. Let’s delve into the world of this essential power distribution transformer, exploring its components, functionality, benefits, and more.

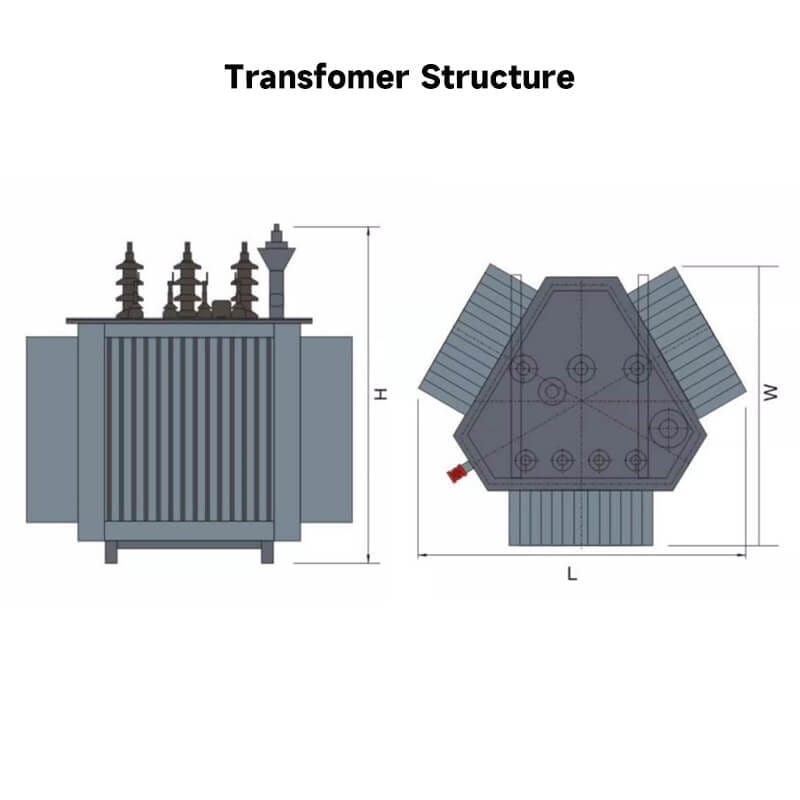

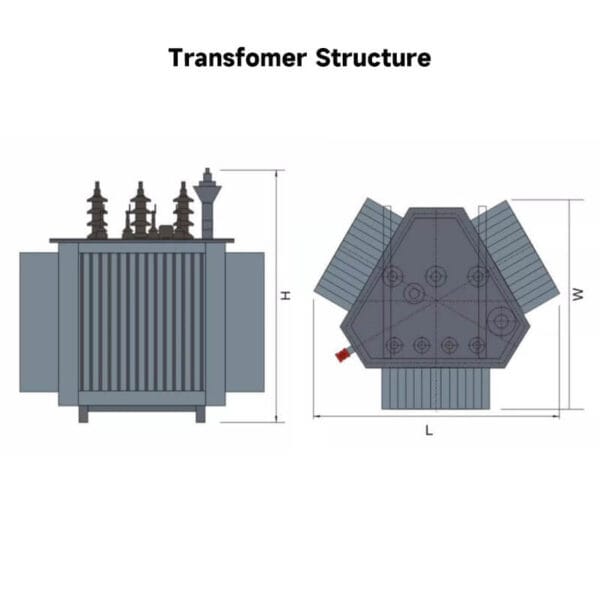

Core Components

An oil-immersed power distribution transformer consists of several critical components that work together to enable efficient energy conversion.

The core, typically made of laminated silicon steel, is the heart of the transformer. It provides a low-reluctance path for magnetic flux, minimizing energy loss. The laminations reduce eddy current losses, a key factor in maintaining the efficiency of the power distribution transformer.

Windings, composed of high-conductivity copper or aluminum, are wrapped around the core. The primary winding receives electrical energy, while the secondary winding delivers the transformed voltage. The design and arrangement of these windings directly impact the transformer’s performance, ensuring optimal coupling and minimal leakage.

The tank, a robust enclosure, houses the core and windings. It is filled with insulating oil, which serves two main purposes: it acts as an electrical insulator, preventing short circuits, and as a cooling agent, dissipating heat generated during operation. The oil’s properties are crucial for the longevity and reliability of the oil-immersed power distribution transformer.

How It Works

The oil-immersed power distribution transformer operates on the principle of electromagnetic induction, similar to other transformers. When alternating current flows through the primary winding, it creates a varying magnetic field in the core. This magnetic field induces an alternating current in the secondary winding, with the voltage ratio determined by the number of turns in each winding.

The insulating oil enhances this process by preventing electrical arcing and transferring heat away from the core and windings. As the transformer operates, heat is absorbed by the oil, which then circulates—either naturally or via pumps—to the tank walls, where the heat is released into the surrounding environment. This cooling mechanism ensures the oil-immersed power distribution transformer operates within safe temperature limits.

Key Advantages

One of the primary advantages of an oil-immersed power distribution transformer is its high efficiency. The combination of low-loss core materials, optimized windings, and effective oil cooling minimizes energy waste, making it ideal for large-scale power distribution.

Durability is another standout feature. The sealed tank and robust construction protect internal components from dust, moisture, and mechanical damage, allowing the transformer to withstand harsh outdoor and industrial environments. With proper maintenance, an oil-immersed power distribution transformer can have a service life of 20 to 30 years.

The cooling capacity of the oil is a significant benefit. Compared to dry-type transformers, oil-immersed models can handle higher loads without overheating, making them suitable for applications with fluctuating power demands, such as urban grids and industrial facilities.

Safety is also a priority. Modern oil-immersed power distribution transformers use fire-resistant or low-flammability oil, reducing the risk of fires. Additionally, pressure relief valves and other safety devices prevent tank rupture in case of excessive internal pressure.

Applications

Oil-immersed power distribution transformers are widely used across various sectors. In urban power systems, they step down high-voltage electricity from transmission lines to voltages suitable for homes and businesses. Industrial plants rely on them to power heavy machinery, where their high load-handling capacity is essential.

They are also common in renewable energy projects, such as wind farms and solar parks, where they convert the electricity generated into a form compatible with the grid. Rural areas, too, benefit from these transformers, as their durability ensures a reliable power supply in remote locations.

Maintenance Tips

To keep an oil-immersed power distribution transformer in top condition, regular maintenance is necessary. Inspecting the oil level and quality is critical—contaminated or degraded oil can reduce insulation and cooling efficiency, so periodic testing and replacement are essential.

Checking for leaks in the tank and connections prevents oil loss and environmental contamination. Cleaning the tank exterior and ensuring ventilation around the transformer helps maintain effective cooling. Additionally, testing electrical parameters, such as insulation resistance and winding resistance, identifies potential issues before they escalate.

Future Trends

The future of oil-immersed power distribution transformers is focused on enhancing efficiency and sustainability. Manufacturers are developing low-loss core materials and advanced oil formulations that improve thermal conductivity and reduce environmental impact. Smart monitoring systems, integrated into modern models, allow real-time tracking of temperature, oil quality, and load levels, enabling predictive maintenance and reducing downtime.

As the demand for reliable power grows—driven by urbanization and renewable energy adoption—the oil-immersed power distribution transformer remains a cornerstone of efficient, durable, and safe power distribution. Its ability to adapt to evolving needs ensures it will continue to play a vital role in global electrical systems.

In conclusion, the oil-immersed power distribution transformer is an indispensable asset in modern power networks. Its efficient operation, durability, and versatility make it a preferred choice for diverse applications, ensuring a stable electricity supply for communities and industries alike.

Reviews

There are no reviews yet.