In the evolving landscape of electrical engineering, the three phase oil immersed high power planar transformer emerges as a game-changing innovation, redefining efficiency, compactness, and reliability in high-power applications. Designed to handle heavy electrical loads while maintaining optimal performance, this transformer combines the advantages of planar technology with the robustness of oil immersion cooling, making it a cornerstone in modern power systems.

This article provides an authoritative overview of its design, benefits, applications, and technical nuances, serving as a definitive guide for industry professionals and decision-makers.

| S11-M series 33kV Oil-immersed High Power Planar Transformer | |||||||

Rated Capacity (kVA) | Voltage combinations | Connection Method | No-load loss (W) | Load loss (W) | No-load current (%) | Short-circuit impedance | |

| HV(kV) | LV(kV) | ||||||

| 50 | 33 35 38.5 | 0.4 0.416 0.420 0.440 | Dyn11 or Yyn0 | 210 | 1270/1210 | 2 | 6.5 |

| 100 | 290 | 2120/2020 | 1.8 | ||||

| 150 | 340 | 2500/2380 | 1.7 | ||||

| 160 | 360 | 2970/2380 | 1.6 | ||||

| 200 | 430 | 3500/3330 | 1.5 | ||||

| 250 | 510 | 4160/3960 | 1.4 | ||||

| 300 | 610 | 5010/4770 | 1.4 | ||||

| 400 | 730 | 5050/5760 | 1.3 | ||||

| 500 | 860 | 7280/6930 | 1.2 | ||||

| 600 | 1040 | 8280 | 1.1 | ||||

| 750 | 1230 | 9900 | 1 | ||||

| 1000 | 1440 | 12150 | 1 | ||||

| 1250 | 1760 | 14670 | 0.9 | ||||

| 1500 | 2120 | 17550 | 0.8 | ||||

| 2000 | 2490 | 20740 | 0.8 | ||||

| 2500 | 2950 | 24420 | 0.8 | ||||

| 3000 | 3510 | 29050 | 0.7 | ||||

| 4000 | 4200 | 34940 | 0.7 | ||||

Understanding Three Phase Oil Immersed High Power Planar Transformers

What Sets This Transformer Apart?

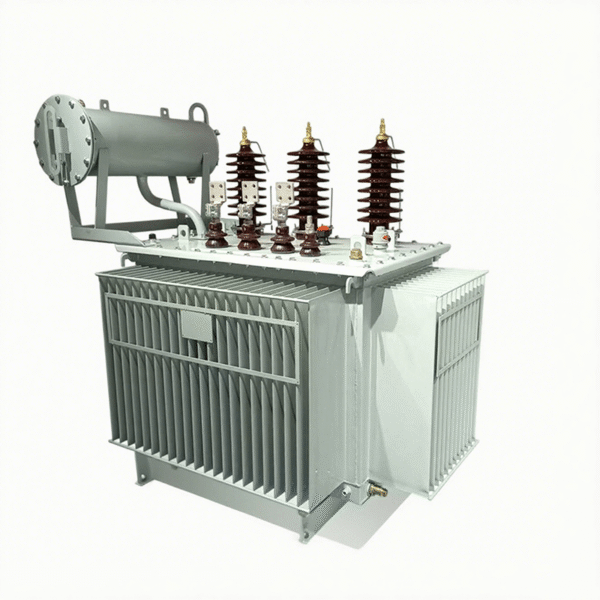

A three phase oil immersed high power planar transformer is a specialized electrical device engineered to convert high-voltage alternating current (AC) between three-phase power systems, leveraging planar magnetic technology and oil immersion for cooling. Unlike traditional transformers with bulky wire-wound cores, planar transformers use flat, printed circuit board (PCB) windings or thin copper sheets arranged in a planar configuration, paired with a low-profile magnetic core. The oil immersion aspect involves submerging the core and windings in dielectric oil, which enhances insulation and dissipates heat efficiently—critical for high-power operations.

This unique combination of three-phase functionality (to handle balanced high-power loads), planar design (for compactness), and oil immersion (for thermal management) positions it as a superior solution for demanding electrical environments where space, efficiency, and reliability are paramount.

Core Principles of Operation

At its core, the three phase oil immersed high power planar transformer operates on the fundamental principle of electromagnetic induction, similar to conventional transformers, but with key enhancements:

- Three-Phase Configuration: It features three sets of primary and secondary windings, each corresponding to one phase of the AC power supply. This allows it to handle three-phase power, which is standard for industrial and high-power applications due to its balanced load distribution and efficient power transmission.

- Planar Magnetic Structure: The flat windings and core minimize magnetic flux leakage and reduce winding resistance, enabling higher efficiency and lower energy losses compared to traditional cylindrical windings.

- Oil Immersion Cooling: The dielectric oil surrounding the core and windings acts as both an insulator (preventing electrical breakdown) and a heat transfer medium (absorbing heat from the windings and core and dissipating it through the transformer tank). This ensures stable operation even under full load for extended periods.

Key Advantages of Three Phase Oil Immersed High Power Planar Transformers

Exceptional Power Density and Compact Design

One of the most significant advantages of planar technology is its high power density. By replacing bulky wire windings with thin, flat conductors (often etched onto PCBs), the transformer achieves a much smaller footprint and lower profile than traditional transformers of equivalent power rating. This compactness is a boon for applications with limited space, such as industrial control cabinets, renewable energy inverters, and marine or aerospace electrical systems.

For example, a 500 kVA three phase oil immersed planar transformer can occupy up to 40% less volume than a conventional transformer of the same capacity, making it ideal for retrofitting into existing electrical setups or tight installations.

Superior Thermal Management with Oil Immersion

High-power transformers generate substantial heat during operation, and effective cooling is critical to prevent overheating and performance degradation. The oil immersion system in these transformers offers several thermal benefits:

- Uniform Heat Distribution: The dielectric oil circulates around the windings and core, ensuring even heat absorption and preventing hotspots.

- High Heat Capacity: Oil has a higher thermal capacity than air, allowing it to absorb more heat before reaching critical temperatures.

- Sealed Environment: The hermetically sealed tank protects internal components from dust, moisture, and contaminants, reducing the risk of thermal insulation breakdown.

This cooling efficiency enables the transformer to operate continuously at high load factors (often up to 110% of rated capacity) without compromising reliability—a key requirement for industrial and utility applications.

Enhanced Efficiency and Energy Savings

Planar transformers minimize energy losses through two key design features:

- Low Winding Resistance: Flat conductors have shorter current paths and larger cross-sectional areas (when compared to round wires of equivalent copper volume), reducing resistive (I²R) losses.

- Reduced Leakage Inductance: The tight coupling between primary and secondary windings in planar designs minimizes magnetic flux leakage, lowering reactive power losses.

When combined with the efficient thermal management of oil immersion, these transformers achieve efficiency levels exceeding 98% at full load—significantly higher than many conventional transformers (which typically range from 95-97%). Over the lifespan of a high-power system, this efficiency translates to substantial energy savings and reduced operational costs.

Technical Features and Design Specifications

Advanced Planar Magnetic Core Technology

The magnetic core is the heart of any transformer, and three phase oil immersed high power planar transformers utilize cutting-edge core materials and designs:

- Material Selection: Cores are often made from high-permeability, low-loss electrical steels (such as grain-oriented silicon steel) or amorphous alloys. These materials minimize hysteresis losses, which occur when the magnetic field reverses direction in AC applications.

- Planar Geometry: The core is constructed in thin, flat laminations stacked to form a compact structure. This design reduces eddy current losses (induced currents in the core material) by limiting the path length of these currents.

- Three-Phase Symmetry: The core is engineered to ensure balanced magnetic flux across all three phases, critical for maintaining stable voltage output and minimizing harmonic distortion in three-phase systems.

Oil Immersion System and Insulation Standards

The oil immersion system is designed to meet stringent insulation and safety standards (such as IEEE C57.12.00 and IEC 60076):

- Dielectric Oil Properties: The oil used is a highly refined mineral oil or synthetic ester with high dielectric strength (typically ≥30 kV/mm), ensuring it can withstand high voltages without breakdown. It also has low viscosity to facilitate heat transfer and high flash point (≥140°C) for fire safety.

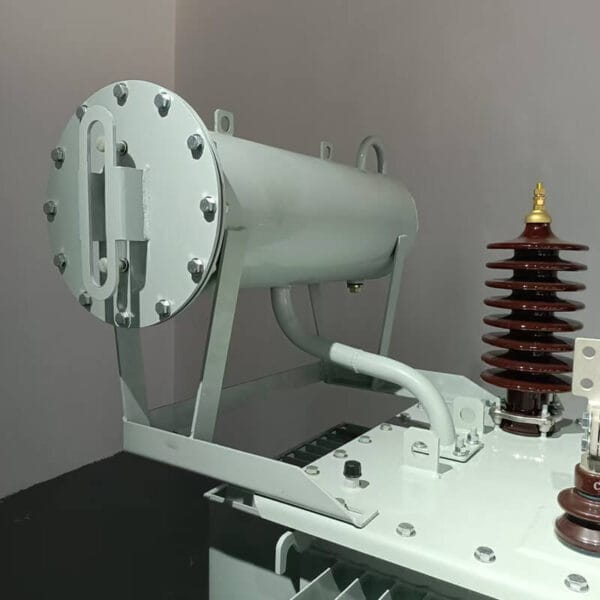

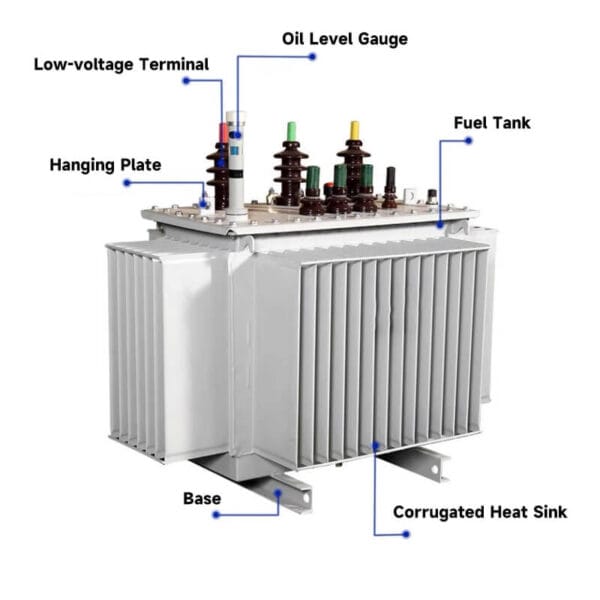

- Tank Design: The steel tank housing the transformer is hermetically sealed to prevent oil leakage and moisture ingress. Some models include conservators (expansion tanks) to accommodate oil volume changes due to temperature fluctuations, maintaining consistent pressure within the system.

- Insulation Class: Windings are insulated with high-temperature materials (such as Nomex® or epoxy resins) rated for continuous operation at 105°C or higher, ensuring compatibility with the thermal profile of oil cooling.

Power Rating and Voltage Range

Three phase oil immersed high power planar transformers are engineered for medium to high power applications, with specifications typically ranging from:

- Power Rating: 100 kVA to 5 MVA (though custom designs can reach up to 10 MVA for specialized industrial use).

- Primary Voltage: 10 kV to 35 kV (suitable for connection to medium-voltage distribution networks).

- Secondary Voltage: 400 V to 10 kV (configurable for direct use in industrial machinery or as input to lower-voltage distribution systems).

- Frequency: 50 Hz or 60 Hz, with designs optimized for specific regional power grids.

These ranges make them versatile for a wide spectrum of electrical systems, from industrial plants to renewable energy farms.

Applications in Modern Electrical Systems

Industrial and Manufacturing Facilities

Three phase oil immersed high power planar transformers are integral to industrial power distribution, supporting heavy machinery such as:

- Motor Drives: Powering large induction motors in pumps, compressors, and conveyor systems, where high torque and stable voltage are critical.

- Arc Furnaces and Welding Equipment: Handling the high currents and variable loads required for metal melting and fabrication processes.

- Automation Systems: Supplying clean, stable power to PLCs (programmable logic controllers) and robotics, where voltage fluctuations can cause operational errors.

Their compact size is particularly valuable in factory settings, where floor space is often at a premium.

Renewable Energy Integration

As the world shifts to clean energy, these transformers play a vital role in connecting renewable sources to the grid:

- Solar Power Plants: Converting DC power from solar inverters to three-phase AC for integration into medium-voltage distribution networks.

- Wind Farms: Stepping up the variable voltage output from wind turbines to match grid specifications, while withstanding the dynamic load changes common in wind energy systems.

- Battery Energy Storage Systems (BESS): Managing high-power charging and discharging cycles in utility-scale energy storage, where efficiency and thermal stability are critical.

Utility and Grid Infrastructure

Utility companies rely on three phase oil immersed high power planar transformers for:

- Substation Distribution: Stepping down medium-voltage grid power to levels suitable for industrial and commercial customers.

- Grid Modernization: Supporting smart grid initiatives by integrating with digital monitoring systems (via sensors embedded in the oil tank) to provide real-time data on temperature, load, and insulation health.

- Backup Power Systems: Ensuring reliable power transfer in emergency generators and UPS (uninterruptible power supply) systems for critical infrastructure (hospitals, data centers, etc.).

Installation, Maintenance, and Safety Guidelines

Proper Installation Practices

Installing a three phase oil immersed high power planar transformer requires adherence to strict guidelines to ensure safety and performance:

- Site Preparation: The installation area must be level, well-ventilated, and free from flammable materials. A concrete foundation or anti-vibration pads may be required to minimize noise and structural stress.

- Lifting and Positioning: The transformer should be lifted using certified lifting lugs (never by the tank cover or bushings) to avoid damage to internal components.

- Electrical Connections: High-voltage bushings (insulating connectors) must be connected to primary and secondary circuits using cables rated for the transformer’s voltage and current. Torque values for connections must follow manufacturer specifications to prevent arcing.

- Oil Level and Pressure Checks: After installation, the oil level in the conservator (if equipped) must be verified, and the tank must be checked for leaks using pressure testing (typically 0.1 MPa for 30 minutes).

Routine Maintenance Procedures

To ensure long-term reliability, regular maintenance is essential:

- Oil Analysis: Periodic sampling and testing of dielectric oil (every 1-2 years) to check for moisture content, acidity, and particulate contamination. Excessive moisture (≥20 ppm) can reduce insulation strength, while high acidity (≥0.1 mg KOH/g) indicates oil degradation.

- Visual Inspections: Checking for oil leaks, corrosion on the tank, and damage to bushings or cooling fins (if applicable).

- Thermal Imaging: Using infrared cameras to detect hotspots in windings or connections, which may indicate loose joints or internal faults.

- Insulation Resistance Testing: Measuring the resistance between windings and ground (using a megohmmeter) to assess insulation health. Values should remain above manufacturer-specified thresholds (typically ≥1000 MΩ at 25°C).

Safety Compliance and Standards

These transformers must comply with global safety standards, including:

- IEC 60076: International standards for power transformers, covering design, testing, and performance.

- IEEE C57.12.28: Specifications for liquid-immersed distribution transformers.

- NFPA 70 (NEC): National Electrical Code requirements for installation, grounding, and overcurrent protection.

Key safety features include pressure relief valves (to prevent tank rupture during internal faults), grounding terminals (for electrostatic discharge), and flame-retardant tank coatings (to reduce fire risk).

Future Trends in Three Phase Oil Immersed High Power Planar Transformers

Integration with Smart Grid Technologies

The next generation of these transformers will feature enhanced digital capabilities, such as:

- IoT Sensors: Embedded sensors for real-time monitoring of oil temperature, pressure, and dissolved gas levels (to detect incipient faults like arcing or overheating).

- Remote Diagnostics: Cloud-based platforms that analyze sensor data to predict maintenance needs, reducing unplanned downtime.

- Grid Synchronization: Compatibility with advanced grid management systems to support bidirectional power flow (critical for renewable energy integration).

Materials Innovation for Sustainability

Manufacturers are increasingly focusing on eco-friendly designs:

- Biodegradable Dielectric Oils: Synthetic esters derived from renewable sources (e.g., vegetable oils) that offer similar performance to mineral oil but are less harmful to the environment in case of leaks.

- Recyclable Components: Use of recycled steel for tanks and cores, along with modular designs that facilitate disassembly and material recovery at end-of-life.

- Low-Carbon Manufacturing: Adoption of energy-efficient production processes (e.g., low-loss core stamping) to reduce the transformer’s carbon footprint.

Higher Power Ratings for Emerging Applications

As demand for high-power electrical systems grows (e.g., in electric vehicle charging stations and hydrogen electrolyzers), manufacturers are developing three phase oil immersed planar transformers with power ratings exceeding 10 MVA. These designs will push the boundaries of planar technology, with innovations such as segmented windings and advanced cooling systems (e.g., forced oil circulation) to handle extreme loads.

Conclusion

The three phase oil immersed high power planar transformer represents a significant advancement in electrical power conversion, offering unmatched power density, efficiency, and reliability for high-demand applications. Its combination of planar technology and oil immersion addresses the key challenges of modern power systems—space constraints, energy efficiency, and thermal management—making it indispensable in industrial, renewable energy, and utility sectors.

As technology evolves, these transformers will continue to play a pivotal role in enabling the transition to smarter, more sustainable electrical grids. For engineers, facility managers, and utility providers, understanding their capabilities and benefits is essential for designing and operating high-performance power systems in the 21st century.

Reviews

There are no reviews yet.