Power Transformer VS Voltage Transformer

Within electrical engineering, power transformers and voltage transformers stand as indispensable assets, underpinning the seamless transmission and distribution of electrical power across modern grids. While both are vital to system functionality, their core purposes, design principles, and operational roles diverge significantly—making each irreplaceable in its own right.

Power transformers are engineered to facilitate efficient energy transfer between circuits via electromagnetic induction, serving as the backbone of long-distance power delivery. Power plants generate electricity at high voltages (often 11kV to 765kV) to minimize transmission losses over hundreds of kilometers, and power transformers step this voltage down to medium (3.3kV–33kV) or low levels (230V–415V) suitable for residential, commercial, and industrial use. Beyond voltage conversion, these transformers are optimized for minimal energy dissipation, with advanced core materials and winding designs that ensure reliability even under continuous, high-load operation.

Voltage transformers (VTs), also known as potential transformers (PTs), are precision instruments designed exclusively for voltage measurement and monitoring. Unlike power transformers, their primary function is not energy transfer but to provide scaled-down, accurate voltage signals (typically 110V or 220V secondary output) that feed into protective relays, meters, and control systems. This voltage reduction allows sensitive monitoring equipment to safely measure high grid voltages (up to 1,200kV) without exposure to dangerous levels. VTs are critical for detecting anomalies like voltage surges or drops, triggering protective actions to prevent equipment damage or system blackouts.

Design and Construction Divergences

The functional differences between power and voltage transformers directly shape their design and construction, with each optimized for its unique operational demands.

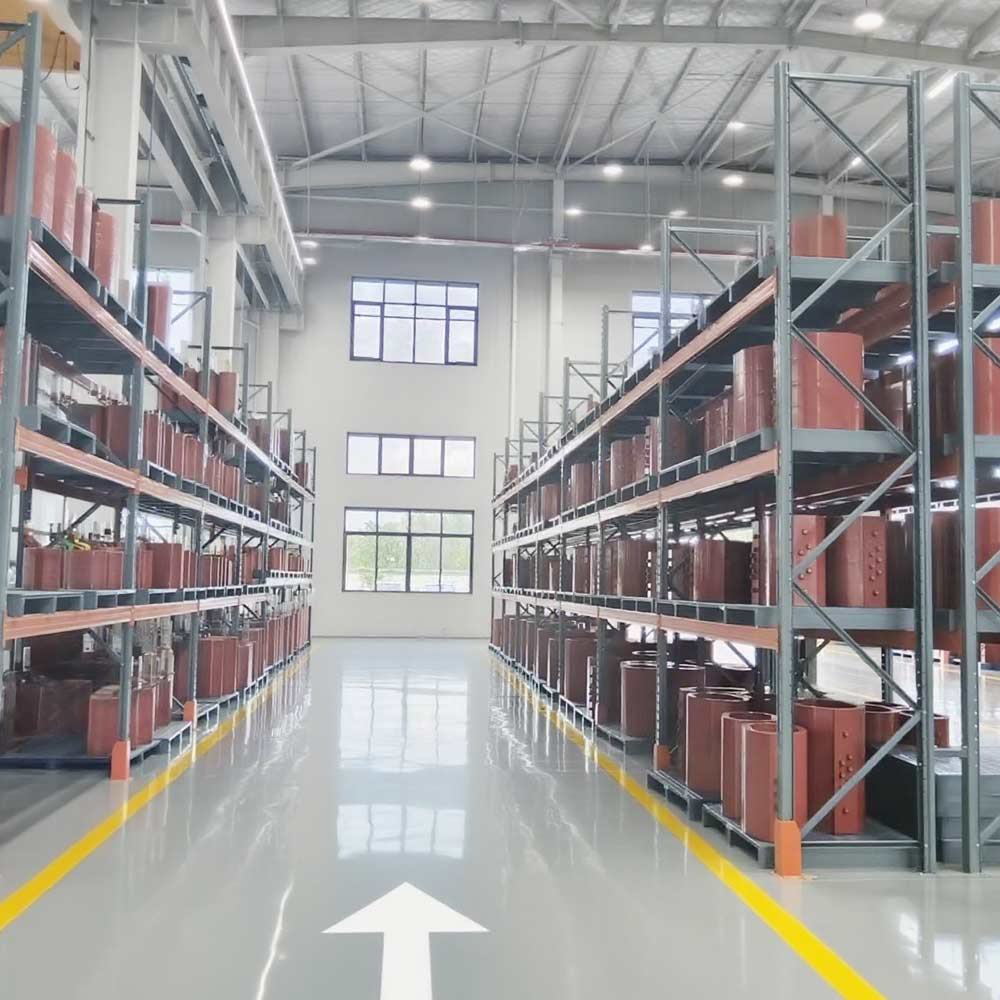

Power transformers are characterized by robust, large-scale builds tailored to handle massive energy loads. Their design incorporates high-grade silicon steel cores and thick copper or aluminum windings to withstand extreme voltages and currents. Rated power capacities range from hundreds of kVA for small distribution units to hundreds of MVA for grid-scale substations. Cooling systems—either oil-immersed (for high-power applications) or dry-type (for indoor, low-risk environments)—are integral to dissipate heat generated during operation, ensuring long-term durability. Lihe Transformer’s power transformer lineup, for instance, integrates vacuum-encapsulated windings and corrosion-resistant tanks to enhance performance in harsh industrial or outdoor settings.

Voltage transformers prioritize precision over power handling, resulting in compact, low-power designs. Constructed with high-precision magnetic cores and fine-gauge windings, they minimize ratio error and phase shift—two critical factors for accurate voltage measurement. Their power ratings are typically below 200VA, as they only supply small currents to monitoring devices rather than powering external loads. VTs often feature hermetically sealed enclosures to protect internal components from environmental factors, making them suitable for both indoor substations and outdoor utility applications.

Operational Context and Industry Applications

The distinct capabilities of power and voltage transformers make them suited to specific use cases across the electrical ecosystem.

Power transformers are deployed at every stage of the power supply chain: substation transformers connect high-voltage transmission lines to regional distribution networks, while pole-mounted or pad-mounted distribution transformers deliver power directly to homes and businesses. They are also essential in renewable energy systems, where they convert variable voltages from solar panels or wind turbines into grid-compatible levels. In industrial settings, custom power transformers support heavy machinery by providing stable, application-specific voltages that ensure optimal performance and safety.

Voltage transformers are integral to power system protection and control. They are installed in substations, industrial plants, and renewable energy facilities to monitor line voltages, validate grid stability, and trigger protective relays during faults. For example, in electric vehicle charging stations, VTs provide real-time voltage data to regulate charging speeds and prevent overloading. In smart grids, they integrate with IoT systems to enable remote monitoring and predictive maintenance, enhancing overall system resilience.

Key Takeaways

Power transformers and voltage transformers are complementary yet distinct components that underpin the reliability and efficiency of electrical systems. Power transformers enable energy delivery by bridging high-voltage transmission and low-voltage consumption, while voltage transformers safeguard system integrity through precise voltage monitoring. Their design differences—size, power rating, and material selection—are direct reflections of their unique roles.

For engineers, utilities, and industrial operators, understanding these distinctions is critical to selecting the right equipment for specific applications. Whether powering a city, protecting critical infrastructure, or integrating renewable energy sources, choosing between a power transformer and a voltage transformer depends on whether the priority is energy transfer or precision measurement. By recognizing their unique strengths, stakeholders can build electrical systems that are safe, efficient, and adaptable to the demands of modern power networks.