How Do Power Transformers Work?

To many people, power transformers are just clunky iron boxes in distribution rooms, even labeled as “only capable of adjusting voltage.” But in fact, power transformers act like versatile stewards of the power system, underpinning the development of modern industry.

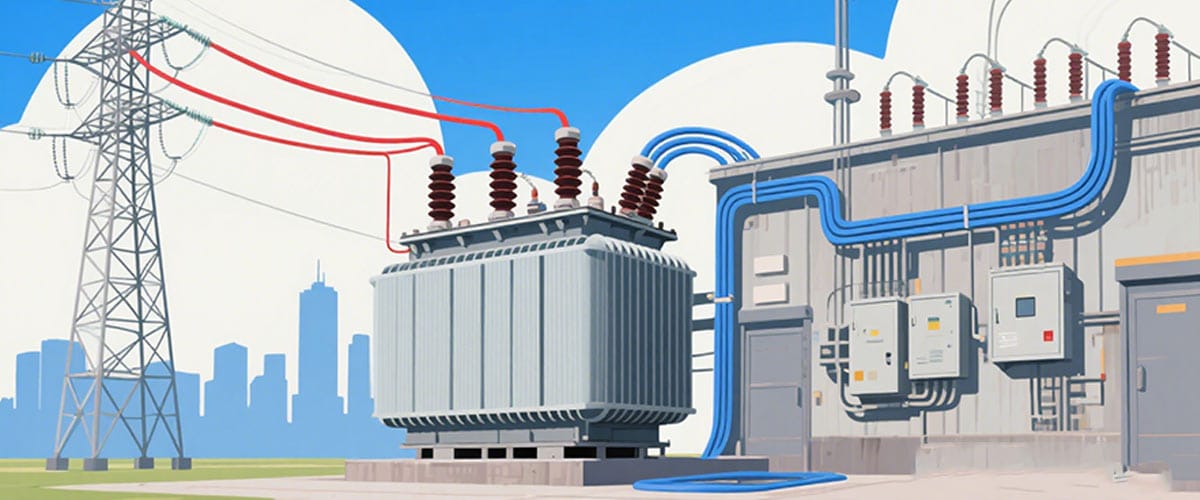

Power transformers are an indispensable key equipment in power systems. They serve as the “hub” of the power network, enabling efficient conversion and transmission of electrical energy between different voltage levels, ensuring that electricity is safely and stably delivered from power plants to thousands of households and various industrial users. So, how exactly do power transformers work?

What Is a Power Transformer?

A power transformer is a static electrical device that transmits electrical energy based on the principle of electromagnetic induction. Its main function is to change the voltage level of alternating current while keeping the frequency unchanged.

In power systems, the voltage of electricity generated by power plants is usually low. If transmitted directly, it would cause significant energy loss. Power transformers can step up the low voltage for long-distance transmission; when the electricity is close to the user end, they can step down the high voltage to meet the voltage requirements of different users.

The Importance of Power Transformers

In power transmission, power loss is proportional to the square of the current. Under a constant power, the higher the voltage, the smaller the current. Therefore, stepping up the voltage through power transformers for long-distance transmission can significantly reduce energy loss.

Meanwhile, different electrical devices require different voltage levels—for example, household electricity is generally 220V, and industrial electricity may be 380V. Power transformers can accurately convert the voltage to the corresponding level, ensuring the normal operation of various electrical equipment.

Core Working Principle of Power Transformers: Electromagnetic Induction

Discovery of Electromagnetic Induction

The phenomenon of electromagnetic induction was discovered by British scientist Michael Faraday in the 1830s. It refers to the fact that when the magnetic flux passing through a closed conductor loop changes, an induced electromotive force is generated in the loop. This discovery laid a solid theoretical foundation for the invention of power transformers.

Application of Electromagnetic Induction in Power Transformers

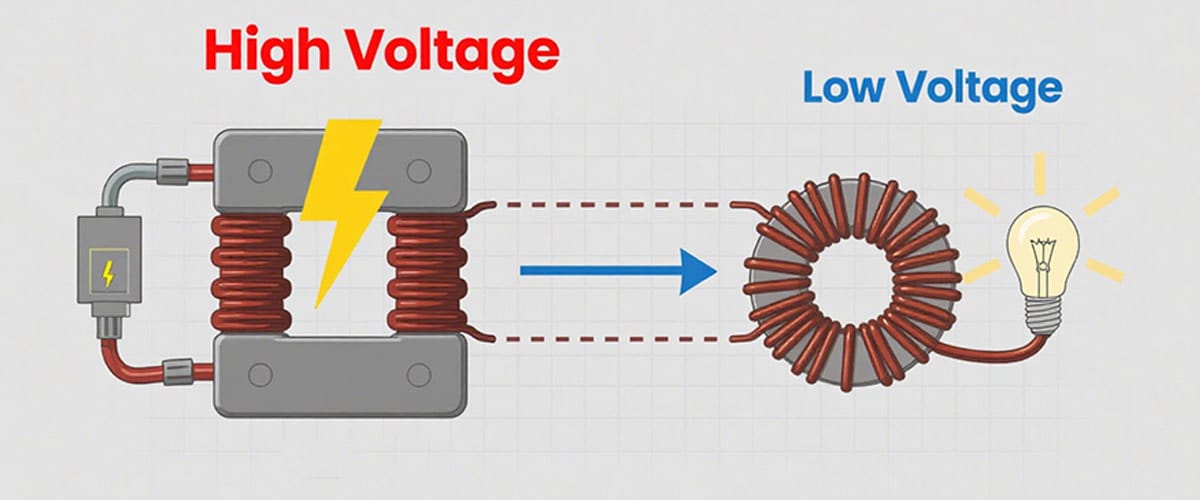

Power transformers operate precisely based on the principle of electromagnetic induction. When the primary winding (primary coil) of a transformer is connected to an AC power source, the alternating current flowing through the primary winding creates an alternating magnetic field.

This alternating magnetic field passes through the iron core and induces an electromotive force in the secondary winding (secondary coil). If the secondary winding forms a closed loop, current will flow, thereby realizing the transmission of electrical energy from the primary winding to the secondary winding.

Key Components of Power Transformers

Windings

Windings are one of the core components of a power transformer, made of insulated wires (usually copper or aluminum wires) wound into coils, divided into primary windings and secondary windings.

The primary winding is connected to the power source to receive electrical energy; the secondary winding is connected to the load to output electrical energy. The number of turns in the windings directly affects the voltage transformation ratio—the more turns, the higher the induced voltage.

Iron Core

The iron core is the magnetic circuit part of the transformer, usually made by stacking thin silicon steel sheets. Its main role is to concentrate the magnetic flux, reduce magnetic resistance, ensure that the magnetic field generated by the primary winding passes through the secondary winding to the maximum extent, and improve energy transmission efficiency.

Silicon steel sheets have good magnetic conductivity, and the stacking method can reduce eddy current losses, as eddy currents are prevented from forming large circulating currents by the insulating layers between the sheets.

Tank and Cooling System

Large power transformers are usually housed in a steel tank filled with transformer oil. Transformer oil serves two purposes: on one hand, it insulates the windings from each other, the iron core, and the tank; on the other hand, it acts as a cooling medium to dissipate heat generated during transformer operation. For transformers with larger capacity, auxiliary cooling devices such as radiators and fans may be equipped to enhance cooling efficiency.

Insulating Bushings

Insulating bushings are insulated devices that allow electrical connections to pass through the transformer tank without causing short circuits. They connect the windings to external cables or lines, ensuring safe and efficient energy transmission. Usually made of ceramics or composite materials, they have good insulation performance and mechanical strength.

Voltage Transformation Process of Power Transformers

Step-Up Process

In power plants, the voltage of electricity generated by generators is relatively low (usually around 10kV-20kV). To reduce energy loss during long-distance transmission, step-up transformers are used to increase the voltage. The number of turns in the secondary winding of a step-up transformer is greater than that in the primary winding.

According to the principle of electromagnetic induction, the output voltage of the secondary winding will be higher than the input voltage of the primary winding, thus realizing voltage step-up. After step-up, electricity can be transmitted over long distances at high voltage and low current, greatly reducing line losses.

Step-Down Process

When electricity is transmitted near the user area, step-down transformers are needed to reduce the high voltage to a level suitable for the user. The number of turns in the primary winding of a step-down transformer is greater than that in the secondary winding, so the output voltage of the secondary winding is lower than the input voltage of the primary winding. For example, high-voltage electricity of 110kV is reduced to 10kV, and further reduced to 220V for household use and 380V for industrial use.

Efficiency and Losses of Power Transformers

Power transformers are not 100% efficient during operation; there are certain energy losses, mainly including copper losses and iron losses. Copper losses are heat losses generated when current flows through the windings due to the resistance of the winding wires, which are proportional to the square of the current. Iron losses are eddy current losses and hysteresis losses generated in the iron core under the action of an alternating magnetic field, related to factors such as power frequency and core materials.

With the continuous development of technology, the efficiency of modern power transformers is very high, with large transformers typically achieving an efficiency of over 95%. Losses can be effectively reduced and transformer operating efficiency improved by using high-conductivity wires, high-quality silicon steel sheets, and optimized structural designs.

Core Functions of Power Transformers

1. Voltage Conversion & Dynamic Voltage Regulation

When it comes to transformers, most people only remember that they can step up or step down voltage. But few realize that voltage conversion is just their most basic capability.

The real core lies in their dynamic regulation of the power grid: when voltage attenuates due to excessive transmission distance, they can automatically compensate for losses; when sudden current surges are caused by the start-up of factory equipment, they can suppress fluctuations like a buffer.

An excellent transformer can even adjust the transformation ratio in real-time through a tap changer, controlling the output voltage fluctuation within ±2%. This means that precision instruments on the production line are no longer troubled by voltage jumps, and enterprises do not need to pay high costs for abnormal equipment shutdowns.

2. Safety Protection & Harmonic Filtering

The function of isolating high-voltage and low-voltage circuits is often underestimated as a basic operation. But it is this “safety gate” that can instantly block the spread of fault current to the low-voltage side during sudden accidents such as lightning strikes and short circuits. This effectively prevents the burning of production lines worth millions of yuan in some factories.

More importantly, it plays a role in harmonic filtering. In modern industrial power grids, harmonics generated by frequency converters and rectifying equipment are like electronic noise, which can accelerate equipment aging.

Transformers, through electromagnetic shielding and impedance characteristics, can block more than 30% of harmonic interference, ensuring the long-term stable operation of sensitive equipment such as CT scanners and CNC machine tools.

3. Impedance Matching & Efficiency Improvement

The statement that “transformers consume electricity themselves” makes many users resist. But the truth is that the no-load loss of new energy-saving transformers is 40% lower than that of traditional models. For example, a 2000kVA transformer can save enough electricity bills annually to pay the salaries of two technical workers.

More importantly, it achieves impedance matching through optimized electromagnetic design. When a motor starts, the transformer can adjust the current output like an “intelligent throttle,” avoiding waste like “using a large horse to pull a small cart.” This implicit efficiency improvement can often increase the overall electricity efficiency by 15%-20%.

4. Energy Revolution & Smart Transformers

In the wave of new energy, transformers have quietly evolved. Facing the volatility of wind power and photovoltaic power generation, dedicated transformers can convert unstable direct current (DC) into stable alternating current (AC) through rapid magnetic flux regulation.

A photovoltaic industrial park achieved 100% local consumption of photovoltaic power generation through a customized transformer solution, saving over 3 million yuan in electricity bills annually.

More advanced smart transformers are equipped with temperature sensing and partial discharge monitoring modules, which can predict insulation aging risks two weeks in advance. This “self-inspection and self-healing” capability makes traditional manual inspection efficiency pale in comparison.

5. Productivity Accelerator: The Overlooked Invisible Driver

What is most easily underestimated is the profound impact of transformers on production rhythms. When an injection molding machine needs an instant large current to start, a properly matched transformer can reduce the response time by 30%; when a precision machine tool requires a voltage fluctuation rate of less than 1%, a specially designed transformer can ensure processing accuracy.

An auto parts manufacturer directly increased its daily production capacity by 8% after replacing it with a customized transformer. This means that choosing the wrong transformer not only results in lost electricity bills but also invisible productivity.

From ensuring safety to improving energy efficiency, from adapting to new energy to optimizing production rhythms, transformers have long transcended traditional cognitive boundaries. When your factory faces high electricity bills or frequent equipment failures, it may be time to re-evaluate the true value of this “iron lump.”

Conclusion

As a key device in the power system, power transformers realize voltage transformation through the principle of electromagnetic induction, providing a guarantee for the efficient transmission and rational distribution of electrical energy.

Understanding the working principle, key components, and voltage transformation process of power transformers helps us better understand the operation mechanism of the power system and also makes us pay more attention to the maintenance of power transformers to ensure the safe and stable operation of the power system.