Choosing the Right Electrical Transformer Box for Your Project?

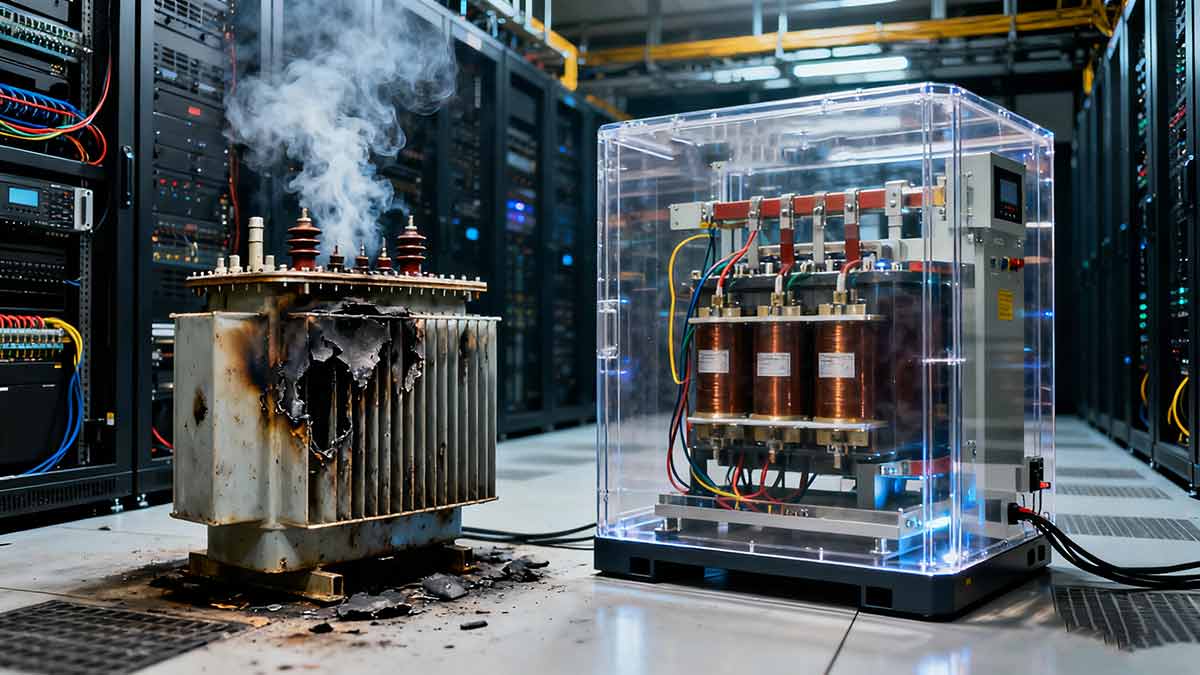

Struggling to select the perfect electrical transformer box for your project? You’re not alone—even seasoned engineers and project managers find this decision daunting. Opting for the wrong unit can lead to energy inefficiency, safety hazards, costly downtime, and premature replacements.

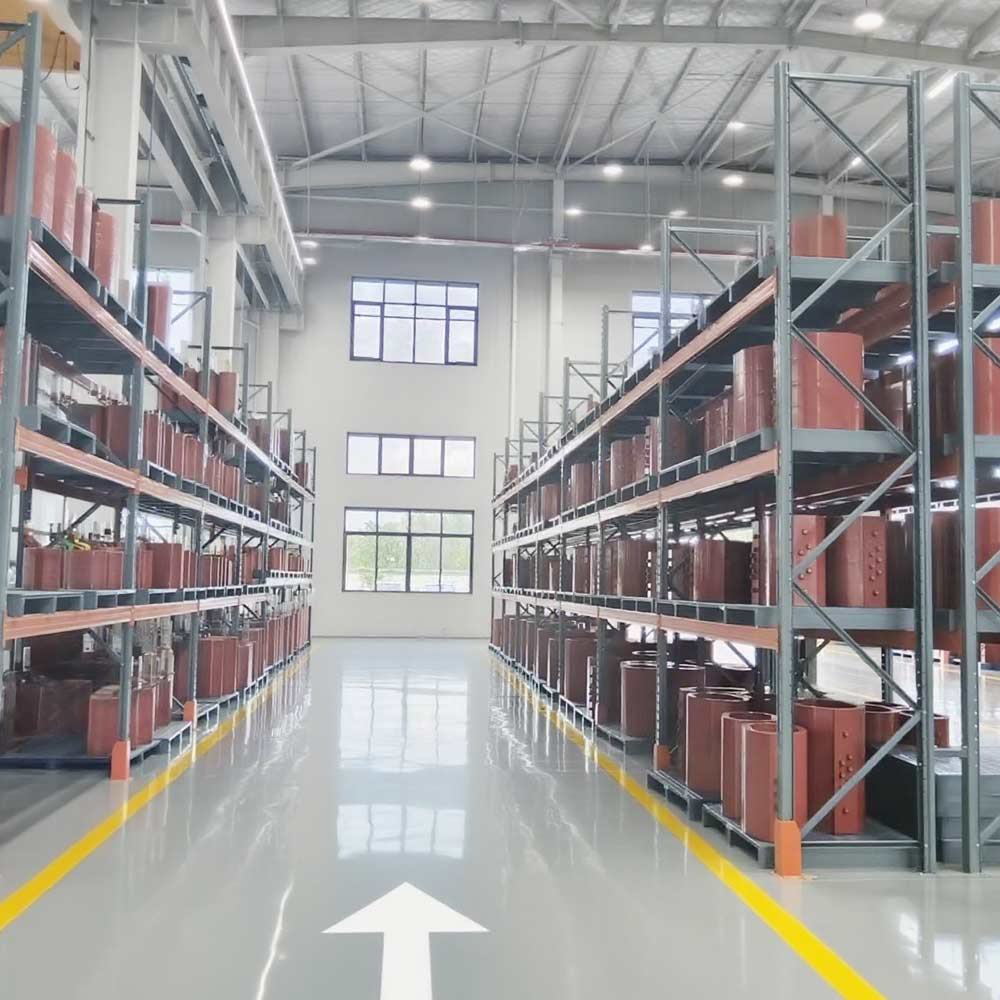

At Lihe Transformer—your trusted manufacturer of high-performance, customizable transformer solutions—we simplify this process. Our transformer boxes are engineered to balance current demands, environmental resilience, safety compliance, and long-term scalability. Choosing the right Lihe transformer box involves assessing your project’s unique needs, understanding product types, sizing correctly, and planning for the future.

In this guide, Lihe Transformer walks you through every step of the selection process. Whether you’re working on a residential development, commercial building, or industrial facility, we’ll help you make an informed decision that aligns with your goals.

1 Assessing Your Needs: Key Factors in Transformer Box Selection?

Overwhelmed by the endless transformer box options? Lihe Transformer’s secret to simplifying this choice lies in prioritizing your project’s core requirements. By focusing on critical factors, you can narrow down options and select a unit that fits like a custom solution.

Assessing your needs starts with a deep dive into load demands, voltage specifications, installation environment, space constraints, and growth plans. Lihe’s engineering team specializes in translating these factors into tailored transformer box recommendations—ensuring no detail is overlooked.

Core Needs Assessment with Lihe Transformer

- Load Requirements:

- Calculate total connected load and peak demand (Lihe’s load analysis tool ensures accuracy).

- Factor in load diversity (not all equipment operates simultaneously) to avoid oversizing.

- Plan for future growth: Lihe recommends a 10–20% capacity buffer to accommodate new equipment or expanded operations.

- A recent client underestimated growth and had to replace their transformer box within 2 years—Lihe’s proactive load analysis would have prevented this costly downtime.

- Voltage Specifications:

- Determine primary (input) and secondary (output) voltage needs (Lihe offers flexible configurations, e.g., 480V/208Y-120V).

- Evaluate voltage regulation requirements for sensitive equipment (Lihe’s precision-engineered units maintain stable voltage within ±1%).

- Address harmonic distortion: For non-linear loads (e.g., LEDs, VFDs), Lihe’s K-rated transformer boxes mitigate overheating risks.

- Environmental Conditions:

- Classify installation as indoor or outdoor (Lihe offers specialized designs for both).

- Assess temperature, humidity, and exposure to contaminants (e.g., salt, dust) to select appropriate enclosures.

- Space & Accessibility:

- Measure available floor/wall space (Lihe’s compact models fit tight urban or industrial settings).

- Consider weight restrictions and maintenance access (Lihe’s pad-mounted units feature easy-to-open enclosures for servicing).

| Factor | Key Considerations | Lihe Transformer Solution |

|---|---|---|

| Load Requirements | Total load, peak demand, future growth | Custom load analysis + 10–20% capacity buffer |

| Voltage Specifications | Input/output voltages, regulation, harmonics | Flexible configurations + K-rated units |

| Environment | Indoor/outdoor, temperature, contaminants | Specialized enclosures (sealed, corrosion-resistant) |

| Space & Accessibility | Available area, weight, maintenance access | Compact designs + user-friendly enclosures |

Lihe’s expertise shines in complex projects. For a data center with harmonic-rich loads, our team identified the need for K-rated transformer boxes during the assessment phase—preventing overheating and extending equipment life by 15+ years.

2 Types and Applications: Matching Transformer Boxes to Project Requirements?

Confused about which transformer box type aligns with your project? Lihe Transformer offers four core types—each engineered for specific environments and applications. The key is matching the unit’s design to your project’s unique demands.

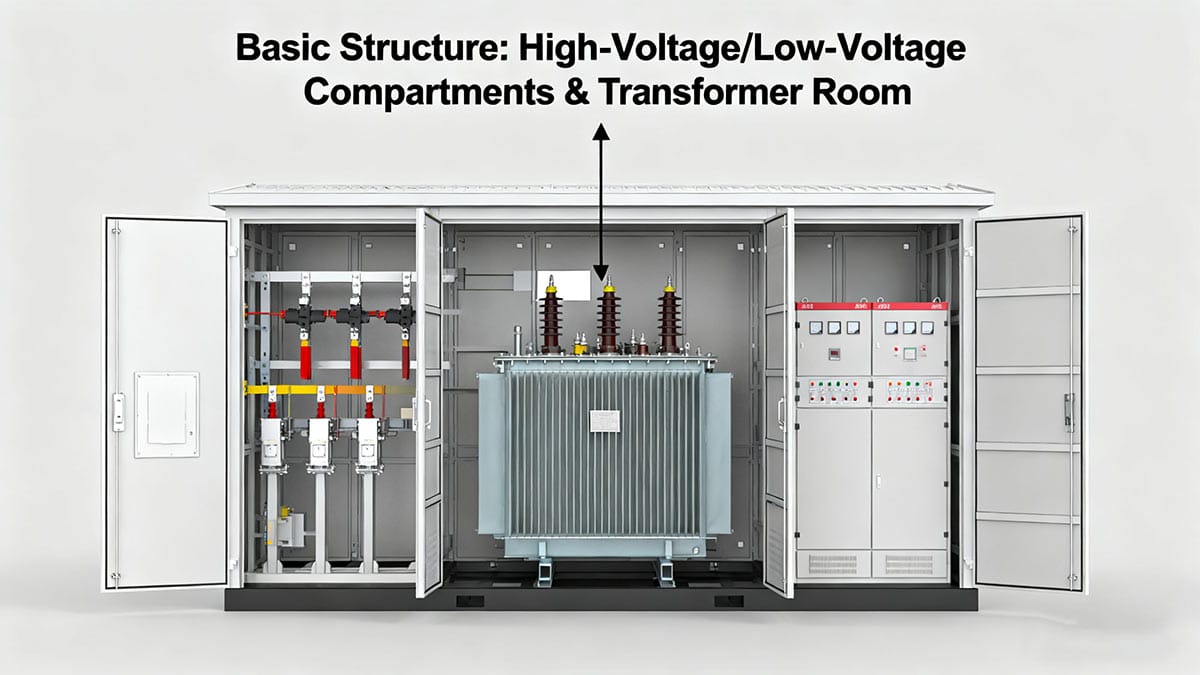

Lihe’s transformer boxes are tailored to residential, commercial, and industrial needs: dry-type for indoor safety, oil-filled for outdoor high-capacity use, pad-mounted for urban settings, and pole-mounted for rural distribution. Below, we break down each type and its ideal use cases.

Lihe Transformer Box Types & Applications

- Dry-Type Transformer Boxes:

- Features: Air-cooled, no liquid insulation, fire-resistant (UL 1561 certified).

- Ideal Applications: Hospitals, data centers, commercial buildings (indoor, moisture-sensitive environments).

- Lihe Advantage: Our cast-resin dry-type units eliminate oil leak risks, making them perfect for healthcare facilities (we recently supplied 50+ units for a hospital renovation).

- Oil-Filled Transformer Boxes:

- Features: Oil-insulated, high-efficiency cooling, suitable for high capacities (up to 765 kV).

- Ideal Applications: Utility substations, heavy industrial facilities, outdoor installations.

- Lihe Advantage: Biodegradable oil options reduce environmental risk; advanced cooling systems handle extreme temperatures (tested to -40°C to 55°C).

- Pad-Mounted Transformer Boxes:

- Features: Ground-level installation, tamper-resistant enclosures, landscapable design.

- Ideal Applications: Urban residential areas, commercial districts, small industrial parks.

- Lihe Advantage: Our low-profile units blend with surroundings; corrosion-resistant coatings withstand coastal or industrial pollution.

- Pole-Mounted Transformer Boxes:

- Features: Elevated installation, space-saving, cost-effective for rural areas.

- Ideal Applications: Suburban/residential distribution, rural utility networks.

- Lihe Advantage: Lightweight yet durable (steel enclosures with anti-rust treatment); easy to install on standard utility poles.

| Type | Environment | Capacity Range | Maintenance | Lihe’s Ideal Applications |

|---|---|---|---|---|

| Dry-Type | Indoor | Up to 35 kV | Low | Hospitals, data centers, office buildings |

| Oil-Filled | Outdoor | Up to 765 kV | Moderate | Utility substations, heavy industry |

| Pad-Mounted | Outdoor | Up to 35 kV | Moderate | Urban residential, commercial districts |

| Pole-Mounted | Outdoor | Up to 35 kV | Moderate | Rural distribution, suburban neighborhoods |

Lihe’s versatility solves unique challenges. For a coastal eco-sensitive project, we replaced oil-filled units with dry-type transformer boxes to eliminate leak risks—aligning with environmental regulations while meeting power demands. For an urban renewal project, our pad-mounted units replaced unsightly pole-mounted models, improving the neighborhood’s aesthetic while enhancing maintenance access.

3 Power and Voltage Considerations: Sizing Your Transformer Box Correctly?

Worried about undersizing or oversizing your transformer box? Lihe Transformer emphasizes that correct sizing is critical to efficiency, cost savings, and system reliability. A poorly sized unit wastes energy, risks overheating, and leads to premature failure.

Sizing a Lihe transformer box involves calculating load demand, accounting for power factor, and planning for growth. Our engineering team uses precision tools to ensure your unit operates at peak efficiency (50–70% load) while accommodating future expansion.

Lihe’s Transformer Box Sizing Process

- Accurate Load Calculation:

- Sum connected equipment power requirements (kW) and convert to kVA (kVA = kW / Power Factor).

- Apply diversity factors (0.7–0.9) to account for non-simultaneous operation (Lihe’s software automates this calculation).

- Example: A 60kW load with 0.8 power factor requires a 75kVA transformer box (60 / 0.8 = 75kVA).

- Power Factor Optimization:

- Low power factor (≤0.8) increases kVA demand (Lihe’s power factor correction capacitors boost efficiency by 10–15%).

- For inductive loads (motors, pumps), Lihe’s transformers are calibrated to handle reactive power without capacity loss.

- Voltage Ratio Matching:

- Select primary/secondary voltage ratio (e.g., 4160V→480V) to align with your power source and load needs.

- Ensure voltage regulation within acceptable limits (Lihe’s units maintain ±1% regulation for sensitive electronics).

- Future Growth Buffer:

- Allocate 10–20% extra capacity for load increases (e.g., EV charging, new equipment).

- Lihe’s modular designs allow easy capacity upgrades without full replacement.

| Factor | Consideration | Lihe Transformer Solution |

|---|---|---|

| Load Calculation | Connected load, diversity factor | Precision sizing software + expert analysis |

| Power Factor | Reactive power, efficiency | Correction capacitors + optimized designs |

| Voltage Ratio | Input/output match, regulation | Custom ratios + tight regulation (±1%) |

| Future Growth | Load expansion, upgrades | 10–20% buffer + modular designs |

Lihe’s sizing expertise prevents costly mistakes. For a water treatment plant, we accounted for motor inrush currents during sizing—selecting a 100kVA transformer box to handle 3x starting current, avoiding voltage dips and equipment damage. For a residential development, our team applied a 0.8 diversity factor, downsizing from a 100kVA to 75kVA unit—saving the client $8,000 upfront.

4 Environmental and Safety Factors: Choosing a Transformer Box for Optimal Performance?

Overlooking environmental and safety factors can lead to transformer box failure and hazards. Lihe Transformer engineers each unit to withstand its installation environment while meeting global safety standards (IEC, ANSI, IEEE). The goal is to ensure reliable performance and protect personnel, equipment, and the environment.

Lihe’s transformer boxes are designed to address temperature extremes, moisture, corrosion, fire risks, and noise—tailored to your project’s specific conditions. Below, we break down key considerations and our solutions.

Lihe’s Environmental & Safety Solutions

- Temperature Resilience:

- Extreme heat (deserts, industrial plants): Lihe’s oil-filled units feature forced-air cooling; dry-type models use high-temperature insulation (Class H).

- Extreme cold (polar regions, high altitudes): Oil heaters and low-viscosity oil prevent freezing; sealed enclosures block snow/ice.

- Moisture & Humidity Protection:

- High-humidity environments (coastal areas, warehouses): Lihe’s IP67-rated sealed enclosures prevent condensation; desiccant packs absorb moisture.

- Flood-prone areas: Elevated pad-mounted units (1m+ above flood level) with waterproof enclosures.

- Corrosion & Contaminant Resistance:

- Coastal/salt environments: Hot-dip galvanized steel enclosures with anti-corrosion coatings.

- Industrial/dusty areas: Filtered ventilation systems prevent debris buildup (Lihe’s self-cleaning filters reduce maintenance).

- Safety Compliance:

- Fire safety (indoor installations): Dry-type units with fire-resistant resin; oil-filled units with spill containment tanks.

- Noise reduction (residential/urban areas): Low-noise designs (≤60dB) with sound-dampening enclosures.

- Regulatory compliance: All Lihe units meet IEC 60076, ANSI C57.12, and local electrical codes.

| Factor | Challenge | Lihe Transformer Solution |

|---|---|---|

| Temperature | Extreme heat/cold, altitude | Forced cooling, low-viscosity oil, insulation |

| Moisture | High humidity, flooding | IP67 enclosures, desiccants, elevated designs |

| Corrosion | Salt, dust, industrial contaminants | Anti-corrosion coatings, filtered ventilation |

| Safety | Fire risk, noise, regulations | Fire-resistant materials, low-noise designs, compliance |

Lihe’s solutions excel in harsh environments. For a desert industrial project, our custom transformer boxes with enhanced cooling systems operated reliably in 55°C heat—outperforming standard units by 20%. For a coastal residential area, our corrosion-resistant pad-mounted units withstood salt spray for 10+ years with zero maintenance issues.

5 Cost-Effectiveness and Future-Proofing: Long-Term Considerations in Transformer Box Selection?

Balancing upfront costs with long-term value? Lihe Transformer emphasizes that the cheapest option today often leads to higher expenses tomorrow. A cost-effective, future-proof transformer box minimizes total cost of ownership (TCO) while adapting to evolving needs (e.g., renewable integration, load growth).

Lihe’s transformer boxes are engineered for efficiency, scalability, and durability—delivering long-term savings through reduced energy costs, minimal maintenance, and extended lifespan (25+ years). Below, we break down key long-term considerations.

Lihe’s Long-Term Value Focus

- Energy Efficiency:

- High-efficiency designs (up to 99.5% efficiency) reduce no-load and full-load losses (Lihe’s premium units save $1,000–$3,000 annually in energy costs).

- Compliance with IE3/IE4 efficiency standards ensures regulatory adherence and long-term savings.

- Example: A Lihe 75kVA high-efficiency transformer box pays back its 10% price premium in 3 years via energy savings.

- Smart Monitoring & Maintenance:

- Built-in sensors track temperature, load, and fault conditions (Lihe’s remote monitoring platform alerts to issues before failure).

- Predictive maintenance capabilities reduce downtime (Lihe’s units require servicing only every 5–7 years, vs. 2–3 years for standard models).

- Scalability & Adaptability:

- Modular designs allow capacity upgrades (e.g., adding windings for higher kVA) without full replacement.

- Compatibility with renewable energy (solar, wind): Lihe’s bi-directional transformer boxes handle grid-tie and backfeed.

- Readiness for smart grids: Integrated communication ports (Modbus, IoT) enable real-time load management.

- Total Cost of Ownership (TCO):

- Calculate TCO = Initial Cost + Energy Costs + Maintenance Costs – Resale Value.

- Lihe’s transformer boxes have 30% lower TCO than standard units over 25 years (due to efficiency, durability, and minimal maintenance).

| Factor | Impact on Long-Term Value | Lihe Transformer Advantage |

|---|---|---|

| Energy Efficiency | Reduces operational costs | 99.5% efficiency + IE3/IE4 compliance |

| Smart Monitoring | Prevents costly downtime | Remote alerts + predictive maintenance |

| Scalability | Avoids premature replacement | Modular upgrades + renewable compatibility |

| TCO | Minimizes overall expenses | 30% lower TCO over 25 years |

Lihe’s future-proofing pays off. For a commercial building, our bi-directional transformer boxes allowed seamless integration of rooftop solar panels 5 years after installation—avoiding a $15,000 replacement. For a manufacturing plant, our smart-monitored units detected a potential fault early, preventing a 3-day downtime that would have cost $100,000.

6 Conclusion

Selecting the right electrical transformer box requires more than just matching kVA ratings—it demands a holistic approach to your project’s needs, environment, safety, and long-term goals. At Lihe Transformer, we combine engineering expertise, customizable solutions, and a focus on value to deliver transformer boxes that perform reliably, efficiently, and adaptably.

Lihe’s dry-type, oil-filled, pad-mounted, and pole-mounted transformer boxes are tailored to residential, commercial, and industrial projects. Our sizing process, environmental resilience, and future-proof designs ensure your unit meets current demands while growing with your project. By prioritizing energy efficiency, safety compliance, and scalability, we help you minimize costs and maximize uptime.

Whether you’re upgrading an existing system or planning a new project, Lihe Transformer is your trusted partner. Contact our team today to get a custom transformer box recommendation tailored to your unique requirements.

CERTIFICATE

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer Box