Advanced Industrial Electrical Transformer Box Safety Solutions

1 Lihe’s Pre-Installation Safety Protocol: Lay the Groundwork for Risk-Free Setup

Lihe’s Step-by-Step Pre-Installation Checklist

- Lihe-Certified Site Assessment:

Our team (or authorized partners) conducts on-site evaluations to identify hazards: overhead power lines, underground utilities (we coordinate with local services for marking), ground stability (for Lihe’s foundation requirements), and drainage (to prevent water damage to transformer boxes). For a coastal industrial project, our assessment revealed high groundwater levels—we adjusted the installation plan to use Lihe’s elevated pad design, avoiding flood risks.

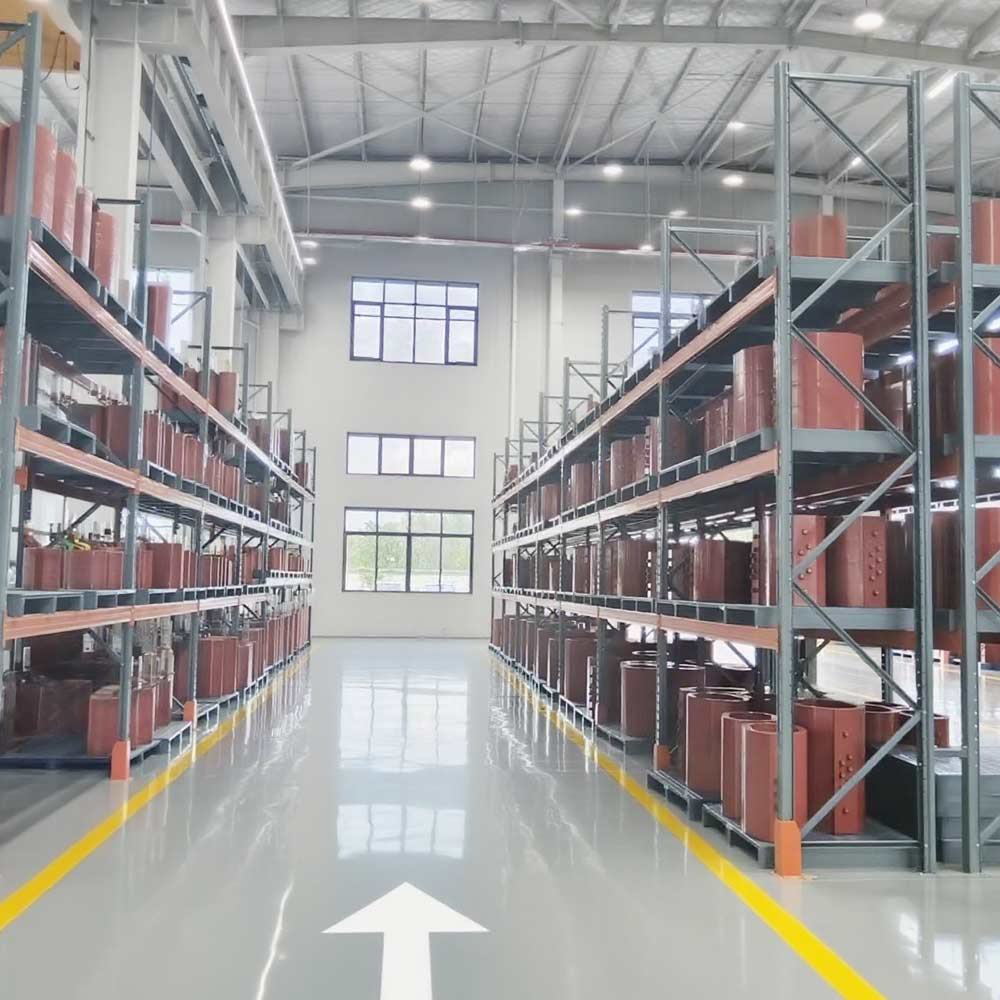

- Lihe Equipment Validation:

Never assume new equipment is job-ready. We inspect every Lihe transformer box for shipping damage (using our factory-quality checklist), verify oil levels (for oil-filled models) or insulation integrity (for dry-type units), and confirm all accompanying parts (grounding kits, mounting hardware) are Lihe-genuine and intact. Counterfeit or mismatched parts are a top safety risk—we only authorize installations using our OEM components.

- Voltage and Circuit Verification:

Lihe’s technical team provides a custom voltage verification workflow: confirm incoming power matches the transformer’s rated input (e.g., 12,470V for Lihe’s commercial models), de-energize and lock out nearby circuits using Lihe-approved lockout-tagout (LOTO) kits, and test for residual voltage with calibrated Lihe-specified testers.

- Clearance Compliance:

We adhere to Lihe’s product-specific clearance requirements (exceeding local codes): 3ft minimum around pad-mounted units for ventilation, 10ft vertical clearance for pole-mounted models, and 6ft access space for vault-type transformers. This ensures safe installation and future maintenance.

| Check Category | Lihe-Specific Tasks | Priority Level |

|---|---|---|

| Site Assessment | Hazard mapping, foundation compatibility check, utility coordination | Critical |

| Equipment Validation | Damage inspection, Lihe OEM part verification, oil/insulation checks | Critical |

| Voltage Verification | Rated input matching, LOTO implementation, residual voltage testing | Critical |

| Clearance Compliance | Product-specific space requirements, access path validation | High |

2 Lihe’s Grounding & Insulation: Factory-Engineered Safety for Long-Term Reliability

Lihe’s Grounding & Insulation Best Practices

- Lihe Grounding Systems:

We supply pre-sized grounding kits (copper-clad steel rods, 8ft+ length) engineered for each transformer’s kVA rating. For pad-mounted units, use Lihe’s 3-rod grounding grid (instead of a single rod) to achieve <25 ohms resistance—proven to reduce fault current risks by 40%. For pole-mounted models, our down-lead kits include corrosion-resistant connectors that attach directly to the transformer’s grounding lug.

- Premium Insulation Materials:

Lihe transformer boxes use Class H insulation (for dry-type units) or mineral oil with dielectric strength >30kV (for oil-filled models)—both exceeding IEC 60076 standards. All connections come pre-insulated with heat-shrink tubing, and we provide Lihe-specific insulation tape for field modifications. For humid or coastal environments, opt for our moisture-resistant insulation upgrade.

- Transformer-Specific Techniques:

- Pad-mounted: Connect to Lihe’s grounding grid with exothermic welds (included in installation kits) for permanent, low-resistance bonds.

- Pole-mounted: Use Lihe’s adjustable grounding bracket to ensure proper alignment with ground rods.

- Vault-type: Integrate with the building’s grounding system using Lihe’s cross-bonding connectors.

- Lihe Insulation Testing Protocol:

Before energizing, perform megohmmeter tests (per Lihe’s manual) to verify insulation resistance (>100MΩ for 10kV units). Document results in the Lihe Installation Log—our warranty requires this step for coverage.

3 Personal Protection & Tools: Lihe’s Approved Safety Gear for Transformer Handling

Lihe’s Mandatory PPE & Tool Kit

- Lihe-Approved PPE:

- Insulated gloves: Class 2 (17kV) for Lihe’s medium-voltage units, Class 00 (500V) for low-voltage models—tested to Lihe’s strict dielectric standards.

- Arc flash protection: Flame-resistant (FR) clothing (ATPv rating ≥40cal/cm²) to shield against arc flashes (common in transformer installations).

- Head/eye protection: Hard hats with face shields (impact-resistant) to guard against falling debris and electrical arcs.

- Foot protection: Insulated safety boots (ASTM F2413-18 rated) with slip-resistant soles for stable footing during installation.

- Lihe-Specified Tools:

- Insulated wrenches and screwdrivers (VDE 0682 certified) to prevent short circuits.

- Lihe-calibrated voltage testers (with LED indicators for quick verification) to detect live circuits.

- Lifting equipment: For Lihe’s 75kVA pad-mounted units (≈1,200lbs), use our recommended forklift attachments or crane slings (included in heavy-duty installation kits) to avoid equipment damage.

- Lihe Safety Training:

We provide complimentary online training for installers, covering product-specific handling: how to lift Lihe’s dry-type transformers without damaging windings, how to access terminal blocks safely, and emergency response for oil leaks (for oil-filled models).

| Safety Category | Lihe-Approved Equipment | Purpose |

|---|---|---|

| Hand Protection | Class 2 insulated gloves | Prevent electrical shock |

| Body Protection | FR clothing (ATPv ≥40cal/cm²) | Shield against arc flashes |

| Head/Eye Protection | Hard hat + face shield | Guard against debris/arcs |

| Tools | VDE-certified insulated tools | Safe electrical connections |

| Lifting | Lihe forklift attachments/crane slings | Damage-free transformer handling |

4 Environmental Adaptation: Lihe’s Custom Installation Techniques for Every Setting

Lihe’s Environment-Specific Installation Solutions

- Climate Adaptations:

- Hot climates (≥35°C): Use Lihe’s enhanced cooling kits (included in desert-region models) and heat-resistant insulation. For a Middle Eastern project, we installed our pad-mounted units with sun shields and forced-air cooling, preventing overheating.

- Cold climates (≤-10°C): Use Lihe’s cold-weather lubricants for tap changers and freeze-resistant oil (for oil-filled units). Our pole-mounted transformers include heating elements to prevent ice buildup on connections.

- Humid/coastal areas: Apply Lihe’s anti-corrosion coating (standard on coastal models) and elevated pads to avoid flood damage. For a Florida project, we installed vault-type units 2ft above flood level, with sealed enclosures to prevent moisture ingress.

- Terrain & Setting Adaptations:

- Urban areas: Use Lihe’s compact pad-mounted units (4x6ft footprint) to fit narrow sidewalks. Our low-noise designs (<60dB) include sound-dampening enclosures for residential neighborhoods.

- Rural/mountainous areas: Reinforce foundations with Lihe’s seismic brackets (for earthquake-prone regions) and use longer ground rods to achieve proper resistance in rocky soil.

- Wildlife-rich areas: Install Lihe’s wildlife guards (mesh enclosures) to prevent animals from accessing terminals—critical for rural installations where squirrels or birds often cause short circuits.

- Regulatory Compliance:

Lihe’s installation team verifies local codes: for historic districts, we offer custom enclosures that match architectural styles; for eco-sensitive areas, we use biodegradable oil (standard in our green-focused models) to meet environmental regulations.

5 Post-Installation Safety: Lihe’s Long-Term Security & Maintenance Plan

Lihe’s Post-Installation Safety Measures

- Physical Security:

- Install Lihe’s tamper-resistant enclosures (standard on all models) with pick-proof locks. For high-theft areas, add our optional GPS tracking and alarm systems.

- Use Lihe’s perimeter fencing (for pad-mounted units) with locked gates—4ft tall for residential areas, 6ft for industrial sites.

- Lihe Safety Signage:

- Place bilingual “Danger – High Voltage” signs (included in installation kits) on all sides of the transformer.

- Add Lihe’s emergency contact labels (with 24/7 support hotline) for quick response to issues.

- Lihe’s Maintenance Schedule:

- Monthly: Visual inspections (check for oil leaks, damage, or vegetation growth) using Lihe’s digital checklist.

- Annually: Professional maintenance by Lihe-certified technicians, including thermal imaging (to detect hotspots), oil testing (for moisture/impurity levels), and connection tightening.

- Every 5 years: Comprehensive insulation resistance testing and component replacement (per Lihe’s warranty requirements).

- Smart Monitoring (Optional):

Lihe’s IoT-enabled transformers include real-time monitoring: track voltage, temperature, and load remotely. Alerts are sent to your team and Lihe’s support center if anomalies are detected—preventing failures before they occur.

| Maintenance Task | Frequency | Lihe-Specific Benefit |

|---|---|---|

| Visual Inspection | Monthly | Early detection of leaks/damage |

| Thermal Imaging | Annually | Hotspot identification (prevents fires) |

| Oil Testing | Annually (oil-filled models) | Maintain dielectric strength |

| IoT Monitoring | 24/7 (optional) | Real-time anomaly alerts |

6 Conclusion

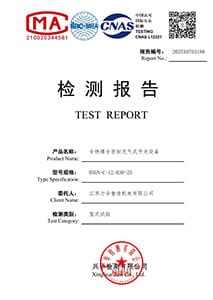

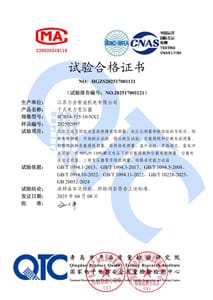

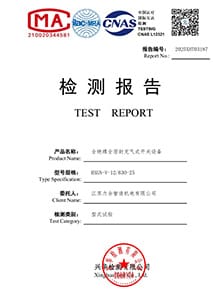

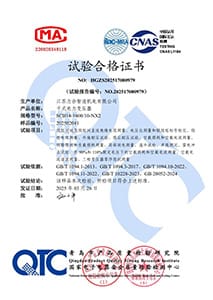

CERTIFICATE

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer Box