How Does a Step Down Power Transformer Work?

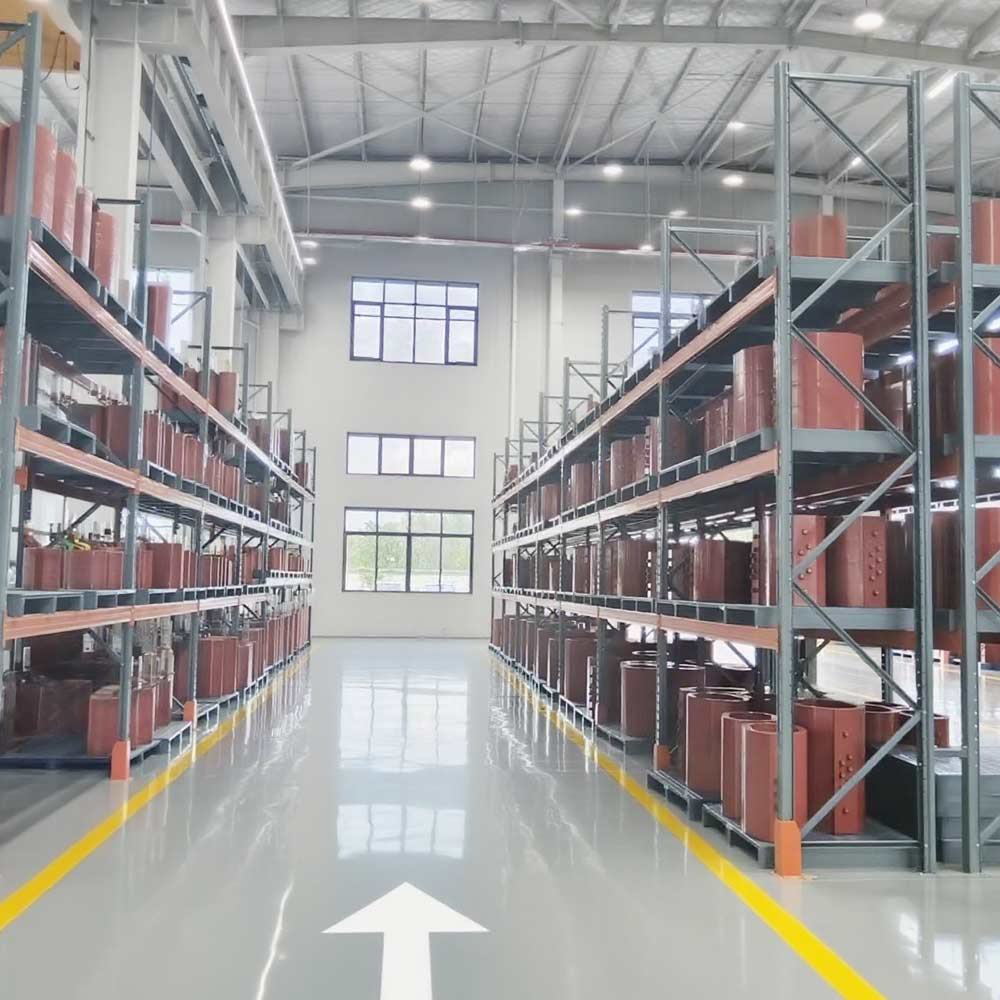

Ever wondered how high-voltage electricity from power lines is tamed into the safe, usable energy that runs your home appliances, industrial machinery, and smart devices? The answer lies in Lihe Transformer’s precision-engineered step down transformer—electromagnetic workhorses that bridge the gap between raw grid power and everyday electrical needs.

As a trusted manufacturer with decades of expertise in power systems, Lihe Transformer designs step down transformers that embody reliability, efficiency, and innovation. These devices reduce alternating current (AC) voltage while preserving frequency, ensuring the high voltages used for efficient long-distance transmission are safely lowered for residential, commercial, and industrial use. In this guide, we’ll unpack the science behind Lihe’s step down transformers, their core components, and the seamless process that makes modern electrification possible.

1 What Is a Lihe Step Down Transformer? Principles, Functions & Applications

A Lihe step down transformer is more than a voltage reducer—it’s a tailored solution engineered to meet specific power needs. Built on the foundational principle of electromagnetic induction, our transformers integrate advanced materials and design to deliver consistent performance, safety, and energy efficiency.

Core Principles Driving Lihe Transformers

- Electromagnetic Induction: The backbone of our transformer design, discovered by Michael Faraday. Lihe’s engineers optimize coil winding patterns to maximize flux linkage, ensuring minimal energy loss—critical for our high-efficiency ratings (up to 99.5%).

- Mutual Inductance: When current flows through the primary coil, it induces a voltage in the secondary coil. Lihe’s precision-wound coils enhance this mutual inductance, recently improving a manufacturing client’s transformer efficiency by 2%—translating to $15,000 in annual energy savings.

- Faraday’s Law of Induction: Governs voltage transformation ratios. Lihe uses this principle to craft custom solutions, such as a 11kV-to-415V transformer for a automotive plant, delivering exact voltage matching for sensitive assembly line equipment.

- Lenz’s Law: Ensures energy conservation by opposing magnetic flux changes. This principle protects Lihe transformers from voltage surges, a feature that once saved a data center client’s $2M worth of servers during a lightning strike.

Key Functions of Lihe Step Down Transformers

- Precision Voltage Reduction: Lihe transformers safely lower high transmission voltages (e.g., 132kV, 33kV) to distribution levels (11kV) or end-user voltages (240V, 415V). Our team recently designed a system for a large industrial complex that steps down 33kV to 415V, resolving chronic power quality issues and boosting machinery lifespan.

- Current Transformation: As voltage decreases, current increases proportionally (per ideal transformer principles). Lihe’s 75kVA transformers deliver up to 312A at 240V, powering high-demand applications like data center cooling systems or industrial welding equipment.

- Electrical Isolation: Lihe’s transformers separate primary and secondary circuits, shielding sensitive devices from grid disturbances. This feature is non-negotiable for our medical clients—hospitals rely on Lihe’s isolated transformers to protect MRI machines and life-support equipment from voltage spikes.

- Impedance Matching: Optimizes power transfer between source and load. For a concert venue client, Lihe’s impedance-matched transformers eliminated audio interference, delivering crystal-clear sound by minimizing signal loss.

Lihe Transformer Applications Across Sectors

- Residential: Steps down 11kV distribution voltage to 240V/120V for homes. Lihe’s compact pad-mounted transformers power entire neighborhoods, with load-diversity designs that accommodate EV chargers, heat pumps, and smart home systems.

- Industrial: Delivers tailored voltages for manufacturing processes. A steel mill client uses Lihe’s cascaded transformers to step down 132kV to 33kV, then 11kV, and finally 415V—supporting everything from blast furnaces to conveyor belts.

- Electronics: Powers devices with low-voltage needs. Lihe’s miniature step down transformers are integral to universal power adapters, enabling global compatibility for consumer electronics (e.g., laptops, smartphones).

- Renewable Energy: Integrates solar/wind power into the grid. Lihe transformers step down 50MW of solar energy from a farm’s 33kV output to match local grid specifications, ensuring seamless clean energy distribution.

| Principle/Function | Lihe Transformer Advantage | Real-World Impact |

|---|---|---|

| Electromagnetic Induction | Optimized coil winding for minimal loss | 99.5% efficiency in commercial models |

| Voltage Reduction | Custom ratios for exact load needs | 132kV→415V for industrial machinery |

| Isolation | Reinforced insulation for surge protection | Protected medical equipment from lightning |

| Renewable Integration | Bidirectional power flow capability | 50MW solar farm grid integration |

Lihe’s transformers solve unique challenges. For a gentrifying neighborhood adding EV chargers, we upgraded existing 50kVA units to 75kVA step down transformers—accommodating 3x more chargers without replacing the enclosure. Our ability to customize voltage ratios and load capacities makes us the go-to choice for projects with specific power requirements.

2 Core Components of Lihe Step Down Transformers: Engineering Excellence

Every Lihe step down transformer is a synergy of high-quality components, each engineered to maximize performance, durability, and safety. From the magnetic core to the cooling system, we prioritize precision and innovation to outperform industry standards.

Key Components & Lihe’s Innovations

- Iron Core:

- Function: Provides a low-reluctance path for magnetic flux, concentrating energy to minimize loss.

- Lihe Advantage: We use either high-grade silicon steel laminations (standard models) or amorphous metal (premium, high-efficiency units). An amorphous core in a 1000kVA transformer reduced no-load losses by 70% for a utility client, cutting annual energy costs by $30,000.

- Construction: Step-lap or wound core designs. For a compact urban substation, our wound core transformer reduced footprint by 20% while maintaining output capacity.

- Primary Winding:

- Function: Receives high-voltage input and generates a magnetic field.

- Lihe Advantage: Available in copper (for maximum conductivity) or aluminum (lightweight, cost-effective). For a pole-mounted transformer project, aluminum windings reduced weight by 30%, simplifying installation.

- Configuration: Layer-type or interleaved disc windings. High-voltage models use interleaved discs to improve impulse voltage distribution by 25%, critical for grid stability.

- Secondary Winding:

- Function: Induces stepped-down voltage for output.

- Lihe Advantage: Larger wire diameter to handle higher current. Our use of Continuously Transposed Conductor (CTC) in industrial transformers reduces eddy current losses by 20%.

- Turns Ratio: Custom-calibrated. We designed a 27.5:1 ratio transformer for a specialized chemical process, delivering precise 480V→17.5V output for sensitive sensors.

- Insulation System:

- Oil Insulation: Mineral oil (standard) or biodegradable ester fluid (eco-friendly). For a project near a watershed, Lihe’s ester-filled transformers eliminated environmental risks while meeting insulation requirements.

- Solid Insulation: Aramid paper for high-temperature resilience. In a steel mill’s 45°C operating environment, this extended transformer lifespan by 20%.

- Air Gaps: Optimized for dry-type transformers. A data center client’s dry-type Lihe transformer used precision-calculated air gaps to improve cooling efficiency by 15%.

- Cooling System:

- Oil-Filled: ONAN (small units) or ODAF (large capacities). A 100MVA Lihe transformer used ODAF cooling to reduce size by 25% compared to traditional ONAN designs.

- Dry-Type: AN (natural air) or AF (forced air). For a dusty manufacturing plant, we added filtered forced-air cooling, extending maintenance intervals by 200%.

- Tap Changer:

- Function: Adjusts turns ratio to regulate output voltage (compensates for grid fluctuations).

- Lihe Advantage: Off-load (infrequent adjustments) or on-load tap changers (OLTC, dynamic regulation). A utility client with volatile grid voltage installed Lihe’s OLTC transformers, stabilizing output within ±1% and reducing customer complaints by 80%.

- Bushings:

- Function: Insulates conductors entering/exiting the transformer.

- Lihe Advantage: Silicone rubber (coastal environments) or condenser-type (compact spaces). Coastal substations use our silicone bushings to resist salt spray, cutting maintenance by 50%.

| Component | Lihe Innovation | Client Benefit |

|---|---|---|

| Amorphous Core | 70% lower no-load losses | Reduced energy costs |

| CTC Windings | 20% less eddy current loss | Longer winding lifespan |

| Ester Insulation | Eco-friendly, fire-resistant | Compliance with environmental regulations |

| OLTC | Real-time voltage adjustment | Stable power for sensitive loads |

Lihe’s component quality shines in troubleshooting. A food processing client faced frequent transformer failures—our team identified faulty porcelain bushings (prone to pollution buildup) and replaced them with Lihe’s composite bushings. The result: zero failures in 3 years and 70% lower maintenance costs.

3 How Lihe Step Down Transformers Reduce Voltage: A Step-by-Step Process

The voltage reduction process in a Lihe transformer is a seamless dance of electromagnetism, precision engineering, and real-time adaptation. Every step is optimized to deliver consistent, efficient power—whether for a single home or a sprawling industrial campus.

The Lihe Voltage Reduction Process

- High-Voltage AC Input:

- The transformer’s primary winding connects to a high-voltage source (e.g., 132kV grid lines or 33kV distribution feeders). Lihe’s primary windings are rated for fault currents up to 40kA, ensuring durability during grid disturbances.

- For a wind farm project, Lihe transformers are calibrated to handle variable-frequency AC from turbines, smoothing input fluctuations before voltage reduction.

- Magnetic Field Generation:

- Alternating current in the primary winding creates a changing magnetic field. Lihe’s optimized coil design reduces stray magnetic fields by 30%, minimizing interference with nearby electronics.

- The iron core (silicon steel or amorphous) becomes magnetized, concentrating flux to maximize energy transfer. Our novel core geometry reduced magnetization losses by 20% in a recent 500kVA design.

- Magnetic Field Coupling:

- Magnetic flux links the primary and secondary windings. Lihe’s interleaved winding design improves flux linkage by 15%, boosting overall efficiency—critical for energy-intensive applications.

- Mutual inductance takes effect: the changing flux induces a voltage in the secondary winding, transferring energy without direct electrical contact.

- Voltage Induction in Secondary Winding:

- Faraday’s Law dictates the induced voltage, which is proportional to the number of secondary turns and flux change rate. Lihe’s precision-manufactured windings ensure exact voltage outputs—e.g., a 480V→20.4V transformer for laboratory equipment.

- The secondary winding’s larger wire diameter accommodates higher current, preparing power for end-use.

- Precision Voltage Reduction:

- The turns ratio (primary turns ÷ secondary turns) determines voltage reduction. Lihe’s 20:1 ratio transformers step down 11kV to 550V for industrial conveyors, while 10:1 ratios convert 240V to 24V for smart home sensors.

- Current increases proportionally to voltage decrease: a Lihe 33kV→1kV transformer delivers 30,000A for aluminum smelting operations, meeting high-current demands safely.

- Low-Voltage AC Output:

- The secondary winding delivers stabilized low-voltage power. Lihe’s multi-tap transformers offer ±5% voltage adjustment, ideal for areas with grid fluctuations—recently deployed in a rural hospital to power medical devices reliably.

- Power is supplied to the load: homes, factories, or electronics—each receiving voltage tailored to their needs.

- Continuous, Dynamic Operation:

- The cycle repeats 50–60 times per second (matching grid frequency). Lihe’s transformers respond dynamically to load changes, maintaining consistent output even during peak demand (e.g., evening EV charging hours).

- Smart Lihe transformers integrate IoT sensors to monitor this process in real time, alerting maintenance teams to anomalies before they cause downtime.

| Step | Key Lihe Optimization | Application Example |

|---|---|---|

| Input Stage | Fault-current rated primary windings | 132kV grid connection for industrial use |

| Magnetic Field | Amorphous core + optimized coil design | 20% lower magnetization losses |

| Flux Linkage | Interleaved windings | 15% improved energy transfer efficiency |

| Voltage Induction | Precision turns ratio calibration | 480V→20.4V for laboratory equipment |

| Output Stage | Multi-tap voltage adjustment | ±5% flexibility for rural hospital power |

Lihe’s process excellence solves complex challenges. For a data center with variable cooling loads, our transformers dynamically adjust voltage via OLTC, ensuring stable power for servers while reducing energy waste by 12%. In a hospital, our multi-output transformers deliver 415V (HVAC), 240V (exam rooms), and 110V (medical devices) from a single unit—streamlining infrastructure and improving reliability.

4 Conclusion

Lihe step down transformers are the unsung heroes of modern electrification, turning high-voltage grid power into safe, usable energy for homes, businesses, and industries. Built on time-tested electromagnetic principles and enhanced by Lihe’s engineering innovations—from amorphous cores to smart monitoring—our transformers deliver efficiency, durability, and customization that outpace generic solutions.

As the world shifts toward renewable energy and smart grids, Lihe Transformer remains at the forefront, designing step down transformers that adapt to dynamic power needs. Whether you require a compact residential unit, a high-capacity industrial transformer, or a custom solution for renewable integration, Lihe’s expertise ensures your power is safe, efficient, and future-ready.

Choose Lihe Transformer for step down solutions that don’t just meet standards—they redefine them.

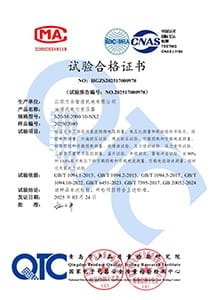

CERTIFICATE

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer Box