A Comprehensive Analysis of Power System and Future Development Trends of Smart Grids

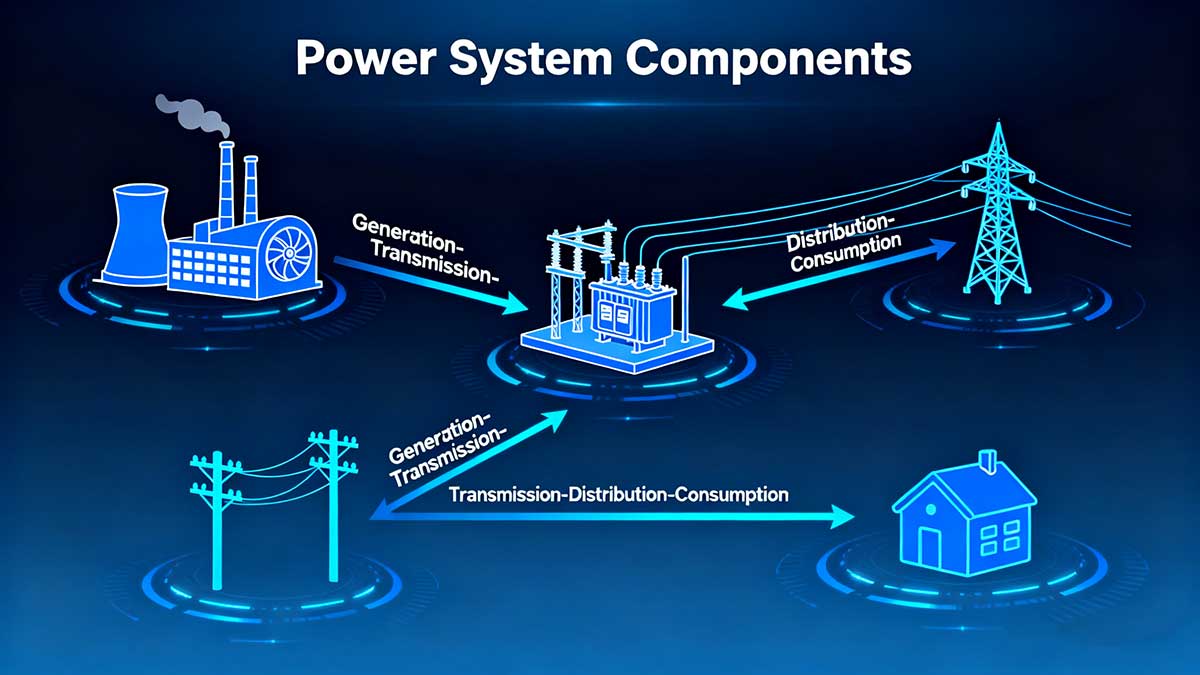

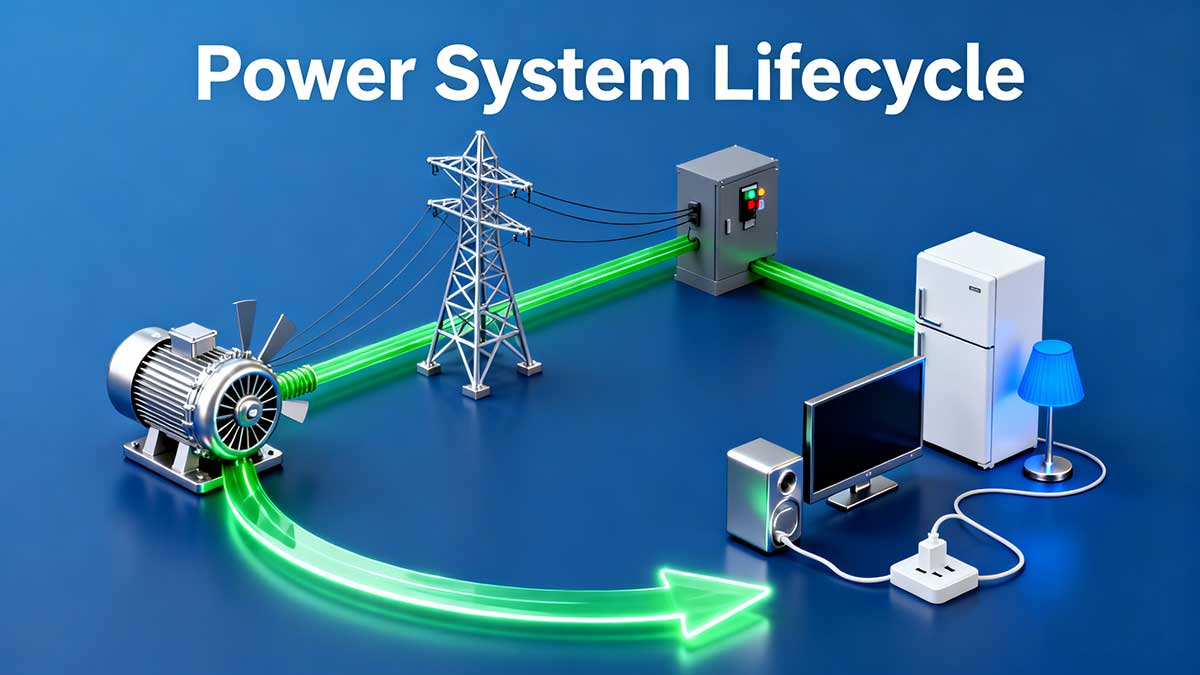

The power system is a vast and complex engineering network. Analogous to the circulatory system of society, it continuously delivers energy to every corner requiring light and power. By professional definition, it is an integrated system for electricity generation and consumption, composed of power plants, substations, transmission lines, distribution networks, and electrical loads. It fulfills the entire process of electricity generation, transmission, distribution, and utilization. With total assets exceeding 2 trillion yuan, accounting for a quarter of China’s state-owned assets, its operational status directly impacts the national economic lifeline and social stability.

I. Structural Dimensions of the Power System

The power system is categorized into three hierarchical levels based on its structure:

- Power Grid: A purely physical network consisting of transmission equipment, transformation equipment, and distribution equipment.

- Power System: A complete electricity system that integrates power generation equipment into the power grid.

- Power Generation System: An expanded system that further incorporates the power generation components of power plants (e.g., boilers and turbines in thermal power plants) into the power system.

II. Operational Characteristics of the Power System

The power system exhibits five distinct operational features:

- Large Economic Scale: As a foundational industry of the national economy, electricity generation directly influences economic health.

- Simultaneity: Electricity is difficult to store on a large scale, so generation, transmission, distribution, and consumption must occur instantaneously, requiring high coordination across all links.

- Centralization: Unified dispatching and management standards are mandatory to ensure safe operation.

- Applicability: Serving all sectors of society, power quality is closely tied to public interests.

- Pioneering Nature: For economic development, power infrastructure must take the lead, with installed capacity requiring moderate advance planning.

III. Power Generation Stage: Converting Energy into Electricity

The power generation stage marks the starting point of the power system, tasked with converting various primary energy sources into clean electricity. Different types of power plants act as large-scale energy converters: they harness natural energy resources and drive generators to rotate and cut magnetic field lines through physical or chemical processes, ultimately producing alternating current (AC) that meets grid requirements. China’s power generation mix is rapidly transitioning from coal-dominated to diversified and clean energy sources. By 2023, the installed capacity of new energy sources exceeded 1 billion kilowatts, accounting for over 35% of the total installed capacity.

3.1 Traditional Power Generation Technologies

- Thermal Power: Currently the dominant generation method, accounting for approximately 60% of China’s total electricity generation. Coal-fired power plants burn coal to heat boilers, producing high-temperature, high-pressure steam that drives turbines and generators. Modern coal-fired units achieve thermal efficiency exceeding 45%, with ultra-supercritical units reaching over 50%. While thermal power boasts mature technology, stable operation, and flexible site selection, it faces challenges of high carbon emissions and pollution. Under the National Plan for the Upgrading and Transformation of Coal-Fired Power Units, over 350 million kilowatts of coal-fired units will undergo energy-saving and carbon-reduction upgrades during the 14th Five-Year Plan period, transitioning from primary power sources to regulatory ones to support renewable energy integration.

- Hydropower: The second-largest power source in China, utilizing water potential energy to drive turbines and generators. The Three Gorges Dam, the world’s largest hydropower station, has an installed capacity of 22.5 million kilowatts and annual generation exceeding 100 billion kilowatt-hours. Hydropower offers rapid start-up, strong peak-shaving capabilities, and low operational costs, playing a key role in grid peak and frequency regulation.

- Nuclear Power: Leveraging nuclear fission chain reactions to generate heat for steam, driving turbine-generator units. A single 1-million-kilowatt nuclear unit can generate 8 billion kilowatt-hours annually with only 30–40 tons of nuclear fuel, minimizing transportation costs. China’s independently developed third-generation nuclear power technology, “Hualong One,” has achieved commercial operation with significantly enhanced safety.

3.2 The Rise of New Energy Power Generation

- Wind Power: Captures wind kinetic energy via wind turbines to drive generators, divided into onshore and offshore wind power. China’s onshore wind power technology is mature, with costs reduced to below 7,000 yuan per kilowatt. Offshore wind resources are abundant, with new installed capacity exceeding 10 million kilowatts in 2023. However, wind power’s intermittency and volatility pose challenges to grid peak shaving, requiring coordination with energy storage or flexible power sources.

- Solar Power: Mainly includes photovoltaic (PV) and concentrated solar power (CSP) technologies. PV power plants directly convert light energy into electricity through the photovoltaic effect. Distributed PV systems can be installed on rooftops and carports for on-site consumption.

- Other Renewable Energies: Technologies such as biomass power generation and geothermal power generation are applied in specific regions. Multi-energy complementarity and integrated energy systems (e.g., “PV + energy storage” and “wind power + hydrogen”) are emerging trends to mitigate output fluctuations of new energy sources.

The future of power generation will see diversified, low-carbon, and distributed development. Transformers, as key equipment for voltage conversion, will grow in importance—especially in scenarios like new energy grid connection and multi-energy integration systems.

IV. Power Transmission Stage: The “Highway” for Electricity

The power transmission stage serves as the backbone network of the power system, responsible for efficiently transmitting electricity from power plants to load centers. Similar to a highway network, it transports electricity from resource-rich remote areas (e.g., coal bases, hydropower stations, and wind farms) to major cities and industrial zones hundreds or thousands of kilometers away.

4.1 Voltage Levels and Transmission Technologies

Voltage level is a key parameter distinguishing transmission lines. China’s standard voltage levels include 220V, 380V, 3kV, 6kV, 10kV, 35kV, 66kV, 110kV, 220kV, 330kV, 500kV, 750kV, and 1000kV. With standardization efforts, non-mainstream levels such as 3kV, 6kV, 20kV, and 66kV are being phased out.

Transmission is classified by voltage:

- High-Voltage (HV) Transmission (35–220kV): Mainly used for regional internal transmission.

- Ultra-High-Voltage (UHV) Transmission (330–750kV): Used for inter-provincial transmission.

- Extra-High-Voltage (EHV) Transmission (above 750kV): Used for ultra-long-distance, large-capacity transmission.

Higher voltage levels reduce transmission losses but increase insulation costs. Studies show that a 1000kV EHV AC transmission line has 4–5 times the capacity of a 500kV line, while its unit capacity loss is only about 25% of the latter. China’s independently developed ±1100kV UHV DC transmission technology can cover distances over 3,000 kilometers, with a single line transmitting over 12 million kilowatts, greatly enhancing energy resource allocation capabilities.

4.2 UHV Transmission and Smart Grids

UHV transmission technology is a “national treasure” of China’s power industry, including AC and DC UHV routes. The successful commissioning of the 1000kV Jindongnan-Nanyang-Jingmen UHV AC pilot project and the ±800kV Xiangjiaba-Shanghai UHV DC transmission project demonstrates China’s global leadership in UHV technology.

Smart grids represent another key development direction for power transmission. By integrating advanced sensing, information and communication, automatic control, and new material technologies, they achieve grid observability, controllability, and adaptability. Key features include:

- Self-Healing Capability: Real-time monitoring of grid status to automatically isolate faults and restore power supply.

- High Reliability: Enhanced power supply reliability through equipment intelligence and network optimization.

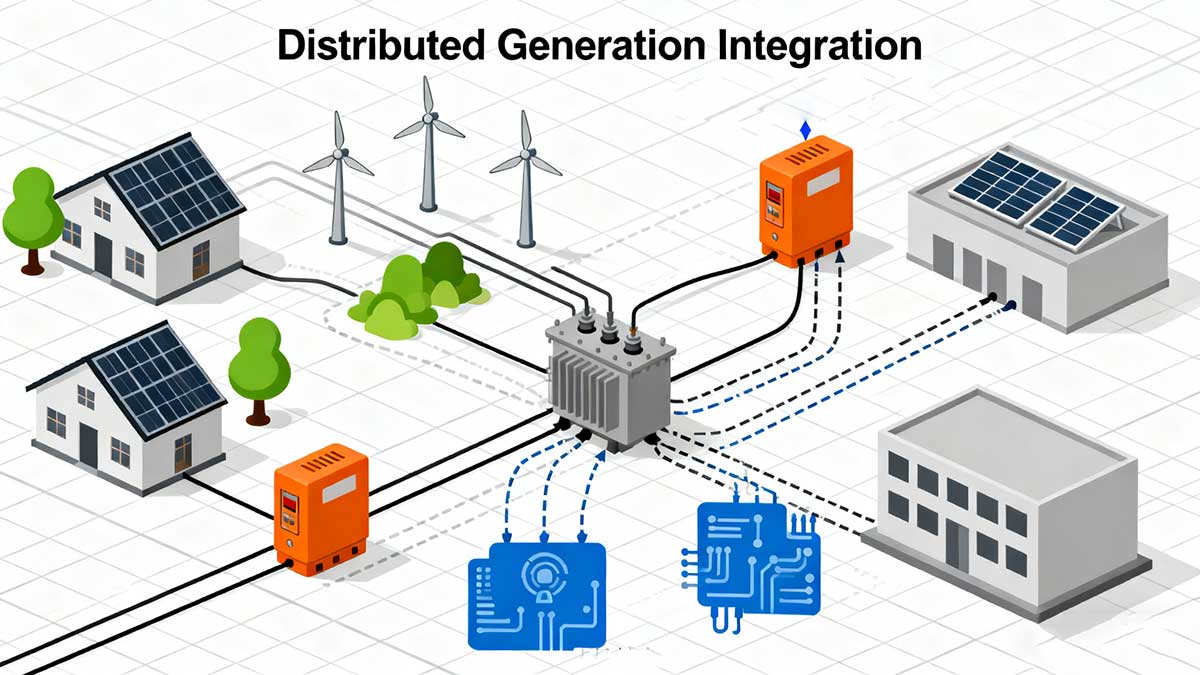

- Renewable Energy Compatibility: Providing plug-and-play access platforms for distributed generation.

- Interactivity: Supporting two-way information and energy exchange with users.

4.3 Transmission Lines and Substations

Transmission lines are structurally divided into overhead lines and cable lines:

- Overhead Lines: Use towers or poles to support conductors, offering low cost and easy maintenance but are highly affected by weather and environment.

- Cable Lines: Higher in cost and complex to lay but space-efficient and reliable, suitable for urban areas.

Conductors are mostly aluminum-clad steel wires, balancing strength and conductivity. Advanced technologies like high-temperature superconducting cables and lightweight composite material towers are gradually moving from laboratories to engineering applications.

Substations are critical nodes in transmission networks, with core functions including:

- Voltage Transformation: Adjusting voltage levels via transformers.

- Power Distribution: Distributing electricity to lines in different directions.

- System Control: Adjusting operational modes using circuit breakers and disconnectors.

- Protection and Monitoring: Detecting system abnormalities and isolating faults.

Substations are classified by location and function: booster stations (usually at power plant exits), hub stations (connecting multiple lines), intermediate stations (segmenting long lines), and terminal stations (at distribution system entrances). Smart substations adopt digital measurement, networked control, and standardized information exchange to achieve equipment intelligence, communication networking, and operational automation—representing the future development trend.

The transmission stage will evolve toward integrating large grids with distributed networks, forming a mesh structure with clear backbones, distinct hierarchies, and coordinated development across voltage levels. Transformers play a core role here, as the reliability of large-capacity, high-voltage transformers directly affects the safe operation of the entire transmission system. Advances in power electronics (e.g., Flexible AC Transmission Systems, FACTS) provide greater operational flexibility for transmission systems.

V. Power Distribution Stage: The “Last Kilometer” of Electricity

The power distribution stage directly serves end-users, distributing electricity from transmission networks to households and businesses. If the transmission system is analogous to the human arterial network, the distribution system is like capillaries, delivering electricity precisely to every power-consuming terminal.

5.1 Composition and Structure of Distribution Networks

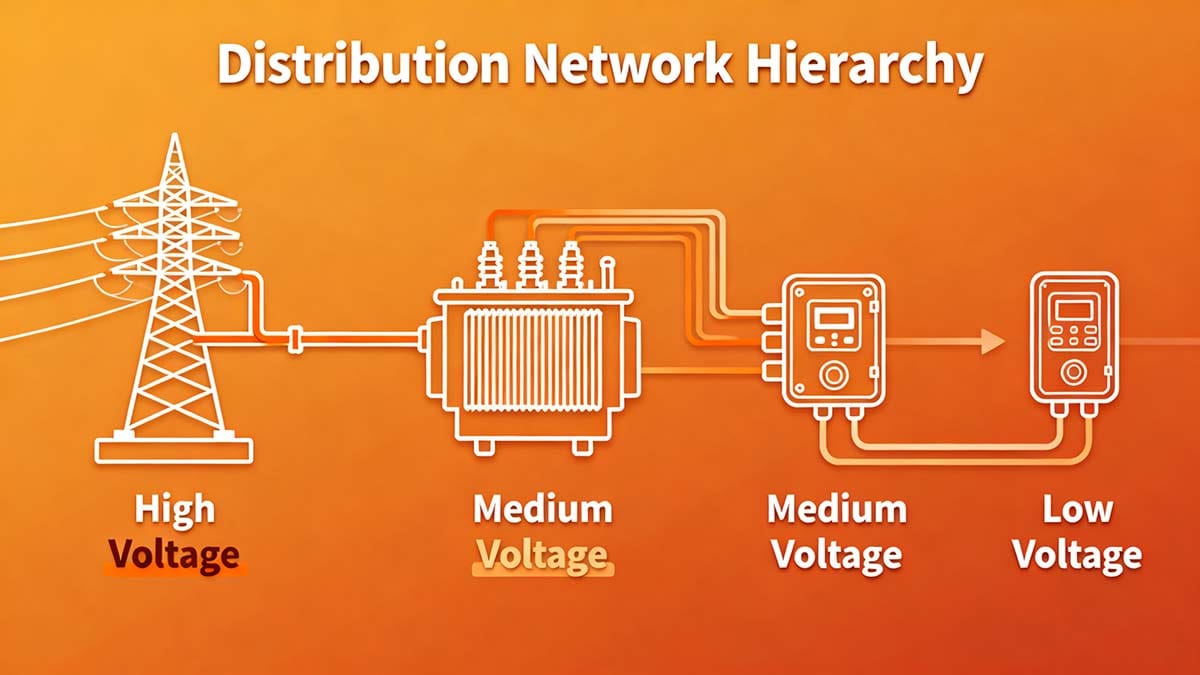

Distribution networks are typically classified by voltage into three levels:

- High-Voltage Distribution Networks (35–110kV): Draw power from high-voltage substations to supply large users like industrial parks and commercial centers.

- Medium-Voltage Distribution Networks (6–10kV): The backbone of urban distribution networks, supplying low-voltage networks via distribution transformers.

- Low-Voltage Distribution Networks (220/380V): Directly connecting residential and small commercial users.

By service area, distribution networks are categorized as:

- Urban Distribution Networks: High load density and reliability requirements, mostly using cable networks and looped power supply.

- Rural Distribution Networks: Sparse loads and large supply radii, mostly using overhead lines and radial power supply.

- Industrial Park Distribution Networks: Concentrated loads with high power quality requirements, adopting diverse supply modes.

A typical distribution system includes distribution substations (switching stations), distribution lines, distribution transformers, switchgear, protection devices, and reactive power compensation equipment. Distribution substations step down 110kV or 35kV to 10kV; distribution lines (overhead or cable) are used, with underground cables prevalent in urban centers; distribution transformers reduce 10kV to 380/220V for user consumption, with capacities typically ranging from 50 to 2000kVA.

5.2 Distribution Automation and Intelligence

Distribution automation is key to improving power supply reliability. It uses automated terminals (e.g., FTUs, DTUs) to monitor distribution network status in real time, automatically isolating faults and restoring power to non-faulty areas. Modern distribution automation systems enable:

- Rapid Fault Location: Accurately identifying fault sections to shorten repair times.

- Network Reconfiguration: Transferring loads via tie switches to minimize outage areas.

- Voltage and Reactive Power Optimization: Automatically adjusting transformer taps and capacitor switching to improve power quality.

The integration of distributed generation transforms distribution networks from passive to active, challenging traditional distribution methods. New energy microgrids—self-governing energy supply systems—coordinate distributed generation, energy storage, and loads, enabling both grid-connected and islanded operation.

5.3 Distribution Transformers and Power Supply Quality

Distribution transformers connect medium- and low-voltage networks, directly impacting power supply quality and energy efficiency. Traditional oil-immersed transformers are gradually replaced by dry-type transformers in urban centers due to fire risks; amorphous alloy transformers, while low in no-load loss, are limited by high costs and noise.

Power supply quality is a key indicator of distribution service levels, including:

- Voltage Quality: Voltage deviation, fluctuation, flicker, three-phase unbalance, and harmonic content.

- Frequency Quality: China’s standard frequency is 50Hz, with an allowable deviation of ±0.1Hz.

- Power Supply Reliability: Urban areas typically achieve a reliability rate exceeding 99.9%.

National standards stipulate:

- For 10kV and below three-phase power supply, the allowable voltage deviation is ±7% of the rated voltage.

- For 220V single-phase power supply, the deviation is +7% to -10%.

- Voltage fluctuation allowances are 2.5% (10kV and below) and 2% (35–110kV).

- Normal three-phase voltage unbalance does not exceed 2%.

Distribution systems use on-load tap changers, static var generators (SVG), and active power filters (APF) to ensure compliance with power quality standards.

Future development of the distribution stage will focus on user experience and energy efficiency improvement, using digital and intelligent technologies to enhance reliability and service quality. The widespread integration of electric vehicle (EV) charging piles, distributed energy, and energy storage presents new technical challenges for distribution network planning, operation, and control—while also creating opportunities for transformer technology innovation. The next generation of smart distribution systems will achieve advanced functions such as self-healing, plug-and-play renewable energy, and demand response, providing safer, more reliable, and greener power supply.

VI. Electricity Consumption Stage: The Final Stage of Electricity Value

The electricity consumption stage is the endpoint of the power system and the final arena where electricity delivers value. Here, electricity is converted into light, heat, and mechanical energy to meet diverse needs of social production and daily life. As the world’s largest electricity consumer, China’s total social electricity consumption exceeded 8.5 trillion kilowatt-hours in 2023, with industrial consumption accounting for ~65%, residential consumption ~15%, and tertiary industry consumption ~20%. With economic development and electrification, load characteristics are becoming more complex, placing higher demands on power system operation.

6.1 Classification and Characteristics of Electrical Loads

Based on the consequences of supply interruptions, loads are categorized into three classes:

- Class I Loads: Interruptions cause casualties, major economic losses, or severe social disorder (e.g., hospitals, data centers, government command centers). These require dual power supplies and, if necessary, emergency backup power.

- Class II Loads: Interruptions cause significant economic losses or social impacts (e.g., key industrial plants, large commercial centers). Dual-circuit power supply is typically adopted to improve reliability.

- Class III Loads: All other loads with relatively low reliability requirements.

By temporal characteristics, loads are divided into:

- Peak Load: The maximum load in a day, determining system installed capacity requirements.

- Valley Load: The minimum load in a day, influencing grid peak-shaving strategies.

- Average Load: The average electricity consumption over a period, reflecting overall load scale.

Load curves are key tools for analyzing consumption characteristics. A typical daily load curve shows a “double-peak” pattern (morning and evening peaks). With increasing air conditioning loads, the peak-valley difference expands in summer. In many Chinese provinces, air conditioning accounts for over 40% of peak load, reducing power system efficiency and investment returns.

6.2 Power Quality and Electricity Safety

Power quality is a critical indicator of consumption experience, including:

- Voltage Quality: Deviation, fluctuation, flicker, and harmonics.

- Frequency Quality: 50Hz standard with ±0.1Hz deviation.

- Supply Continuity: Reflecting outage frequency and duration.

Voltage deviation is the most user-sensitive power quality issue. National standards allow a deviation of +7% to -10% (198V–235V) for 220V single-phase supply. Excessive voltage shortens equipment lifespan, while insufficient voltage may prevent motor startup or cause abnormal operation. Harmonic pollution—mainly from power electronics and arc furnaces—causes transformer overheating, protection malfunctions, and communication interference, requiring mitigation via active filters.

Electricity safety covers personal and equipment safety:

- Personal Safety: Preventing electric shock through protective grounding, residual current devices (RCDs), maintaining safe distances, and using insulated tools.

- Equipment Safety: Preventing overvoltage, overcurrent, and short circuits.

The popularity of distributed generation introduces the risk of islanding—distributed generators continuing to supply local lines after grid outages, endangering maintenance workers. Mitigation requires technical measures (e.g., anti-islanding protection devices) and management measures.

6.3 Demand-Side Management (DSM) and Energy Efficiency Improvement

DSM optimizes user consumption patterns through economic and technical means to maximize overall power system efficiency. The 2023 Measures for Power Demand-Side Management outlines three key initiatives:

- Demand Response: Using price signals or incentives to encourage users to reduce consumption or activate backup power during peak periods, flattening load fluctuations. Pilots in Jiangsu and Guangdong have achieved peak shaving capacities exceeding 5 million kilowatts.

- Energy Efficiency Management: Promoting high-efficiency equipment, energy-saving technologies, and intelligent control systems to reduce electricity consumption per unit of output. Energy efficiency standards for key equipment (e.g., three-phase induction motors, distribution transformers) are continuously upgraded.

- Electricity Substitution: Replacing coal and oil with electricity in transportation, construction, and industry to increase terminal electrification.

Smart electricity consumption is a key future trend. Digital tools like advanced metering infrastructure (AMI) and home energy management systems (HEMS) enable visualized consumption, automated control, and personalized services. Smart meters—installed nationwide—support bidirectional metering, time-of-use pricing, and remote control, laying the foundation for precision marketing and value-added services.

6.4 Emerging Loads and Challenges

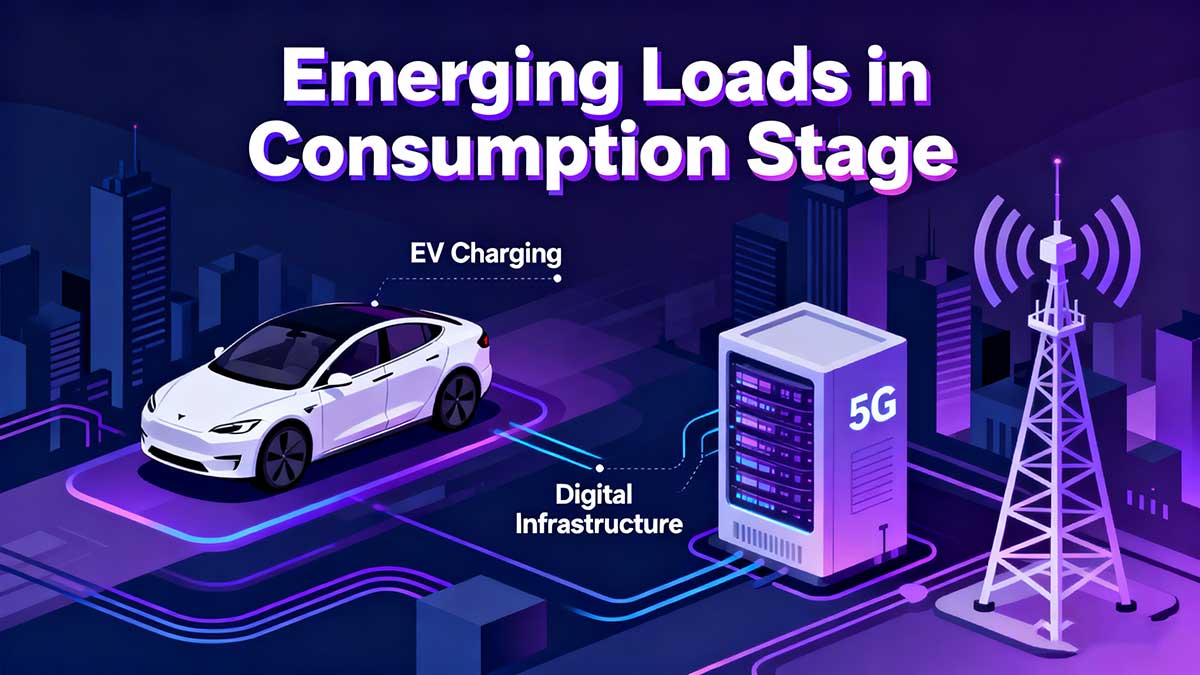

- EV Charging Loads: The fastest-growing emerging load. China’s EV ownership exceeds 20 million, with charging infrastructure capacity over 100 million kilowatts. Uncontrolled charging risks overloading distribution transformers and voltage sags, requiring coordinated development with the grid via smart charging and vehicle-to-grid (V2G) technology. The government is accelerating charging network construction, promoting smart charging innovation, and exploring EV participation in power market transactions.

- Distributed Energy and Microgrids: Reshaping traditional consumption patterns, giving rise to “prosumers” (users who both consume and produce electricity). PV + energy storage systems enable households and enterprises to achieve partial energy self-sufficiency, with surplus power fed into the grid or used for demand response—creating new value streams. This transformation raises new issues for electricity pricing and grid investment recovery mechanisms.

- Digital Infrastructure: Data centers, 5G base stations, and AI computing centers drive electricity demand growth. A single ultra-large data center can consume over 50 megawatts—equivalent to a small city. These loads require ultra-high reliability, typically using dual power supplies + diesel generators + UPS, while also providing adjustable resources for demand response.

- Green Transition: A key component of China’s “dual carbon” goals (peak carbon emissions and carbon neutrality). Mechanisms like green power trading and green certificate trading enable users to participate directly in renewable energy consumption. Key regions and enterprises are encouraged to increase green power consumption. Future electricity-side carbon reduction will become more market-oriented and refined with the improvement of carbon markets.

The electricity consumption stage will shift from passive consumption to active participation, with users playing a more proactive role in power system operation. Transformers—connecting distribution networks to users—directly influence the refinement of electricity management. Looking ahead, technologies adapting to high-proportion renewable energy, high power electronics penetration, and high digitalization will accelerate, providing terminal support for the power system’s low-carbon transition.

VII. The Core Role and Future Development of Transformers

As indispensable key equipment in the power system, transformers silently support voltage transformation and energy distribution across the entire network. From power plants to transmission grids, distribution networks to end-users, transformers play a crucial role at every stage. Accounting for approximately 15% of grid fixed assets, their operational efficiency directly impacts overall grid line losses. With the construction of new power systems, transformer technology faces new opportunities and challenges, with intelligence, high efficiency, and environmental friendliness emerging as industry trends.

7.1 The Key Role of Transformers in Power Systems

Transformers realize AC voltage conversion via electromagnetic induction, with core functions including:

- Voltage Transformation: Step-up transformers increase generator output voltage (10–20kV) to transmission voltage (110–1000kV) to reduce losses; step-down transformers decrease high voltage to distribution voltage (10–35kV) and user voltage (220/380V).

- Energy Transmission: Acting as the “joints” of the power system, they connect grids of different voltage levels to ensure smooth electricity flow.

- System Isolation: Protecting equipment and limiting fault scope through electrical isolation to enhance operational safety.

Power transformers are classified by application:

- Step-Up Transformers: Located at power plant exits, increasing generator voltage to transmission levels.

- Tie Transformers: Connecting transmission networks of different voltage levels.

- Step-Down Transformers: Located in substations, reducing high voltage to distribution levels.

- Distribution Transformers: Reducing medium voltage (10–35kV) to low voltage (220/380V) for user use.

Key performance parameters include rated capacity, rated voltage, no-load loss, load loss, short-circuit impedance, and temperature rise limits. Short-circuit impedance—controlling dynamic stability—is typically 4%–12%. No-load and load losses determine operational efficiency, serving as core indicators for energy efficiency evaluation.

7.2 Intelligent Transformation and Digital Operation & Maintenance

Smart transformers integrate traditional transformers with sensing, communication, and data analysis technologies, enabling real-time condition monitoring, fault early warning, and intelligent regulation. Typical configurations include:

- Oil temperature, oil level, and gas concentration monitoring units.

- Partial discharge on-line detection devices.

- Winding hot-spot temperature monitoring systems.

- On-load tap-changer intelligent control units.

Equipped with edge computing gateways, smart transformers perform on-site data collection, processing, and anomaly diagnosis, uploading information to cloud platforms via 4G/5G or fiber optics. AI-based prognostic and health management (PHM) systems analyze aging trends, predict remaining life, and optimize maintenance strategies—shifting from “periodic maintenance” to “condition-based maintenance.”

Digital twin technology offers a new approach to transformer management. By building virtual models mirroring physical transformers and integrating multi-physics simulation, real-time data, and machine learning, it enables accurate mapping and predictive analysis of operational status. China Southern Power Grid and State Grid have piloted digital twins in key hub substations, significantly improving equipment management.

Blockchain technology shows potential in full-lifecycle transformer management. By establishing tamper-proof equipment records (design, manufacturing, installation, operation, maintenance, decommissioning), it enables quality traceability and responsibility definition—supporting a transparent and efficient transformer supply chain and operation system.

7.3 Transformer Technology Innovation for New Power Systems

High-proportion renewable energy integration imposes new requirements on transformers. Intermittent PV and wind power cause increased voltage fluctuations, demanding transformers with wider voltage regulation ranges and faster response speeds. Traditional mechanical on-load tap-changers struggle to meet these needs, making solid-state transformers (SSTs)—based on power electronics— a research focus.

SSTs use high-frequency transformers and power converters, offering small size, light weight, and flexible control. Key capabilities include:

- Rapid adjustment of voltage amplitude and phase.

- Decoupled control of active and reactive power.

- Proactive power quality management.

- Interconnection of AC and DC systems.

While high costs and unproven reliability limit large-scale commercialization, SSTs are being demonstrated in flexible distribution, data center power supply, and EV charging—with significant future potential.

DC transformers are another critical innovation for new power systems. With the development of high-voltage DC transmission, DC distribution networks, and DC loads, they bridge DC systems of different voltage levels. DC transformer technologies based on modular multilevel converters (MMCs) and dual-active bridges (DABs) are maturing, supporting the construction of AC-DC hybrid grids.

7.4 Future Trends

Transformers will evolve toward higher efficiency, intelligence, and environmental friendliness, with new materials (e.g., nanocomposites), processes (e.g., 3D-printed windings), and structures (e.g., three-dimensional wound cores) emerging. Shifting from passive equipment in traditional systems to active control units in new power systems, transformers will collaborate with generation, grid, and load resources to provide solid support for the clean and low-carbon energy transition.

I can further optimize this English version by adjusting the flow of technical descriptions for better readability or refining specific sections (e.g., UHV transmission or transformer technology) based on your target audience. Would you like me to create a condensed executive summary of this English translation for quick stakeholder review?

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer Box