What is the cooling method of transformer?

Transformers, as core equipment in power systems, generate heat during operation due to iron loss, copper loss, and other factors. If this heat cannot be dissipated in time, it will affect the equipment’s lifespan and even cause failures. Therefore, choosing the right cooling method of transformer is crucial. This article details common transformer cooling methods, their working principles, and applicable scenarios to help you fully understand transformer cooling systems.

1. Oil-Immersed Natural Air Cooling (ONAN): A Simple and Reliable Basic Cooling Method

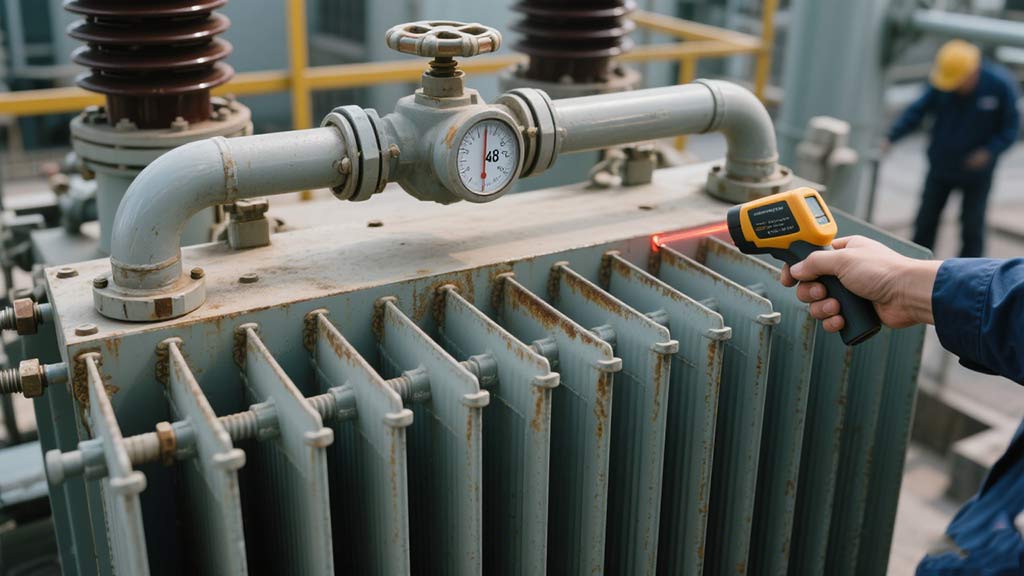

Oil-immersed natural air cooling is the most basic cooling method for transformers. Its core principle relies on the natural convection of oil for heat dissipation: Heat generated inside the transformer is transferred to the insulating oil. Hot oil, with lower density, flows upward. When it reaches the tank walls and radiating pipes, heat is dissipated into the surrounding environment through air convection and thermal conduction. The cooled oil then sinks due to gravity, forming a natural circulation.

This cooling method requires no additional dedicated cooling equipment, featuring a simple structure and easy maintenance. It is suitable for transformers with stable loads and low heat generation.

Application Scenarios:

- Transformers with 31500kVA and below, 35kV and below;

- Transformers with 50000kVA and below, 110kV.

2. Oil-Immersed Forced Air Cooling (ONAF): An Advanced Solution for Enhanced Heat Dissipation

Oil-immersed forced air cooling is an optimized upgrade of oil-immersed natural cooling. It shares the same basic principle but adds fans to the tank walls or radiating pipes. These fans force air flow, accelerating heat dissipation from the surfaces of the tank and radiating pipes, thus significantly improving cooling efficiency.

With the addition of fans, the transformer’s capacity and load-carrying capacity can be increased by approximately 35%, making it suitable for higher load operation.

Heat Dissipation Process:

Heat from the core and windings is first conducted to their surfaces and then transferred to the insulating oil. Hot oil reaches the inner walls of the tank and radiators through natural convection, then conducts heat to the outer surfaces. Finally, heat is dissipated into the air through forced air supply from fans, air convection, and thermal radiation.

Application Scenarios:

- Transformers with 12500kVA to 63000kVA, 35kV to 110kV;

- Transformers with below 75000kVA, 110kV;

- Transformers with 40000kVA and below, 220kV.

3. Forced Oil Circulation Air Cooling (OFAF): An Efficient Choice for High-Load Scenarios

Forced oil circulation air cooling uses oil pumps to force the circulation of insulating oil, breaking the limitations of natural convection. This allows oil to flow through coolers at a faster speed, and when combined with fans to accelerate heat dissipation, its cooling efficiency is much higher than that of natural circulation.

When the oil circulation speed is increased by 3 times, the transformer capacity can be increased by about 30%, making it suitable for medium-high voltage and large-capacity equipment.

Application Scenarios: Transformers with 50000 to 90000kVA, 220kV.

4. Forced Oil Circulation Water Cooling (OFWF): A Specialized Solution for Hydropower Scenarios

Forced oil circulation water cooling operates on the same principle as forced oil air cooling, with the key difference being the use of cooling water instead of fans as the cooling medium. Hot oil is pumped into specially designed coolers by oil pumps, where cooling water absorbs the heat, and the cooled oil is then returned to the tank for circulation.

This method has stronger heat dissipation capacity, especially suitable for scenarios with abundant water resources, making it a common choice for large transformers in hydropower plants.

Application Scenarios: These are typically used for step-up transformers in hydropower plants, with 220kV and above, 60MVA and above.

5. Forced Directed Oil Circulation Air Cooling (ODAF): A Core Cooling Method for High-Voltage, Large-Capacity Equipment

Forced directed oil circulation air cooling is further optimized based on forced oil circulation. Submerged oil pumps send cold oil directly into dedicated oil channels between the core and windings, precisely removing heat from core heating components. The hot oil in the upper layer is pumped out, cooled by coolers, and then returned to the bottom of the tank, forming a directed forced circulation for more efficient and precise heat dissipation.

Application Scenarios:

- Transformers with 75000kVA and above, 110kV;

- Transformers with 120000kVA and above, 220kV;

- High-voltage, large-capacity transformers of 330kV and 500kV classes.

6. Forced Directed Oil Circulation Water Cooling (ODWF): A High-Efficiency Heat Dissipation Solution for Ultra-High-Voltage Equipment

Forced directed oil circulation water cooling combines the advantages of directed oil circulation and water cooling. Cold oil reaches the heat-generating core through dedicated oil channels, while cooling water efficiently absorbs heat, making it suitable for the heat dissipation needs of ultra-high-voltage and ultra-large-capacity transformers.

Application Scenarios: Consistent with ODAF, applicable to transformers with 75000kVA and above, 110kV and higher voltage levels (330kV, 500kV).

Working Principles and Development of Transformer Cooling Systems

Traditional transformer cooling systems are manually controlled. Each group of air-cooled motors relies on thermal relays, and the power circuit is controlled by contactors. The start and stop of fans are determined based on oil temperature and overload conditions. However, this method has obvious drawbacks: All fans must start and stop simultaneously, resulting in large inrush currents during startup, which can easily damage components. When the oil temperature is between 45~55℃, full-load operation is required, leading to energy waste and maintenance difficulties.

In addition, traditional control systems mostly use relays, thermal relays, and contact logic circuits, with complex control logic. During operation, contactors are prone to burnout due to frequent contact and separation, and they lack overload and phase-loss protection, reducing operational reliability and increasing operation and maintenance costs.

Composition of Coolers for Forced Oil and Forced Air Cooling Transformers

The cooler is the core component of the forced oil and forced air cooling system, mainly composed of the following elements:

- Heat exchanger: Facilitates heat exchange between oil and air (or water);

- Fan: Discharges hot air from the heat exchanger to accelerate heat dissipation.

- Motor: Provides power for fans and oil pumps;

- Air duct: Guides air flow to improve cooling efficiency;

- Oil pump: Installed at the lower part of the cooler to drive oil circulation from top to bottom in the heat exchanger.

- Oil flow indicator: Installed at a visible position on the lower part of the cooler for operators to monitor the operation status of the oil pump.

Functions of Transformer Oil Tank and Cooling Device

- Oil tank: Serves as the transformer’s outer shell, housing the core, windings, and transformer oil. It also participates in heat dissipation through its surface, acting as a basic component of the cooling system.

- Cooling device: When a temperature difference occurs in the upper oil of the transformer, the radiator forms an oil circulation, allowing cooled oil to flow back into the tank and reduce oil temperature. By adding fans, oil pumps, or water cooling equipment, cooling efficiency can be further improved to adapt to different load and capacity requirements.

Through this article, you should have a comprehensive understanding of the principles, types, and applications of transformer cooling methods. Choosing the right cooling method can effectively ensure the safe and stable operation of transformers, extend equipment lifespan, and reduce operation and maintenance costs.