Advantages of Oil Immersed Power and Distribution Transformer

- Extended Service Life

Their airtight sealing design effectively isolates internal components from moisture, dust, and other contaminants, significantly slowing down wear and corrosion. Compared to open-type transformers, this structural advantage extends their operational lifespan by over 30%. - Reduced Maintenance Requirements

The fully sealed construction eliminates the need for routine tasks like moisture level inspections, contamination removal, or seal replacements. This not only simplifies upkeep procedures but also cuts maintenance workload by approximately 50%, lowering long-term operational costs. - Improved Operational Reliability

By minimizing exposure to harsh external conditions—such as humidity, pollutants, or temperature fluctuations—hermetic transformers drastically reduce the risk of malfunctions. This makes them particularly reliable in mission-critical settings, including power grid infrastructure and industrial facilities where uninterrupted operation is paramount. - Stronger Environmental Compatibility

The sealed design prevents leaks of insulating oil, a common source of soil and water contamination in traditional transformers. This feature ensures compliance with strict environmental regulations (e.g., EPA standards) and supports eco-friendly operation.

| S11 33kV Oil-immersed Power Distribution Transformer | |||||||

Rated Capacity(kVA) | Voltage combinations | Connection Method | No-load loss (W) | Load loss (W) | No-load current (%) | Short-circuit impedance | |

| HV(kV) | LV(kV) | ||||||

| 50 | 33 35 38.5 | 0.4 0.416 0.420 0.440 | Dyn11 or Yyn0 | 210 | 1270/1210 | 2 | 6.5 |

| 100 | 290 | 2120/2020 | 1.8 | ||||

| 150 | 340 | 2500/2380 | 1.7 | ||||

| 160 | 360 | 2970/2380 | 1.6 | ||||

| 200 | 430 | 3500/3330 | 1.5 | ||||

| 250 | 510 | 4160/3960 | 1.4 | ||||

| 300 | 610 | 5010/4770 | 1.4 | ||||

| 400 | 730 | 5050/5760 | 1.3 | ||||

| 500 | 860 | 7280/6930 | 1.2 | ||||

| 600 | 1040 | 8280 | 1.1 | ||||

| 750 | 1230 | 9900 | 1 | ||||

| 1000 | 1440 | 12150 | 1 | ||||

| 1250 | 1760 | 14670 | 0.9 | ||||

| 1500 | 2120 | 17550 | 0.8 | ||||

| 2000 | 2490 | 20740 | 0.8 | ||||

| 2500 | 2950 | 24420 | 0.8 | ||||

| 3000 | 3510 | 29050 | 0.7 | ||||

| 4000 | 4200 | 34940 | 0.7 | ||||

Power and Distribution Transformer: Core Advantages and Industrial Applications

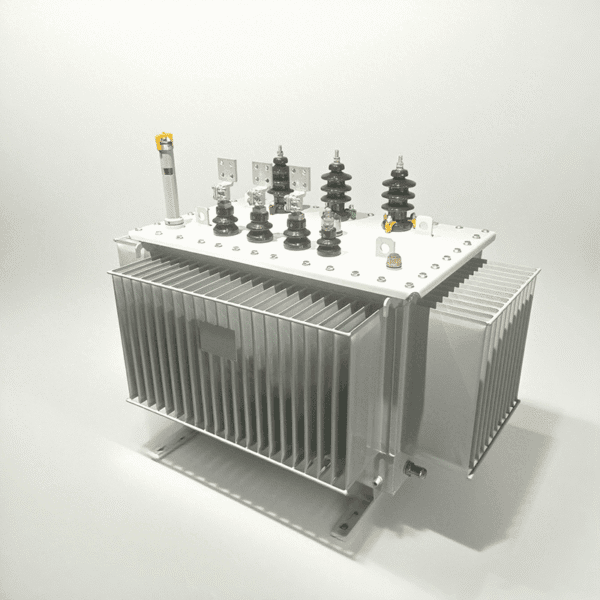

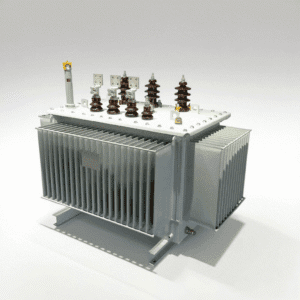

In the complex network of modern power systems, high voltage three phase oil immersed power and distribution transformers stand as critical components, bridging the gap between power generation, transmission, and end – use. These transformers, designed to handle high voltage levels and three – phase electrical currents, play an indispensable role in ensuring efficient, reliable, and safe power distribution across various industries and infrastructure.

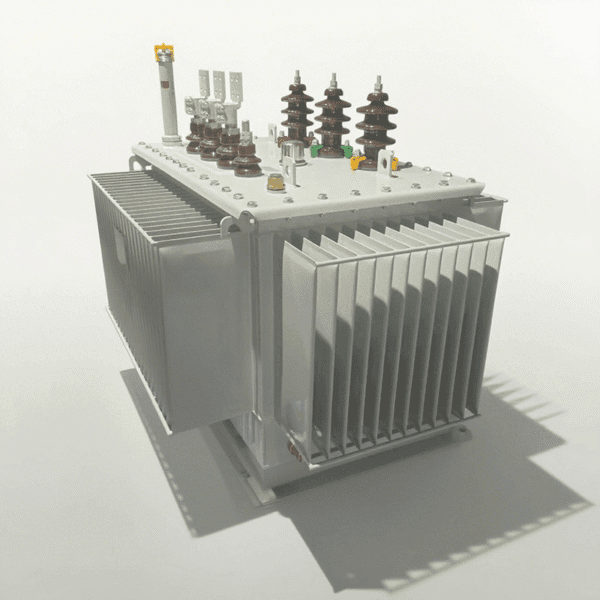

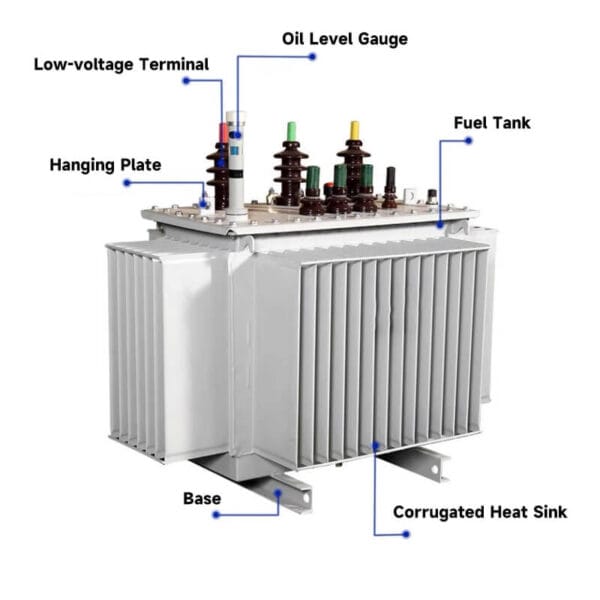

Understanding the Core Design: Why Oil Immersion Matters

The oil immersion technology is a defining feature of these transformers, and it brings with it a host of advantages. The insulating oil, typically a mineral – based or synthetic fluid, serves two primary functions: electrical insulation and heat dissipation.

In terms of electrical insulation, the oil has a much higher dielectric strength than air. This means it can withstand the high voltage gradients present in the transformer’s windings and core without breaking down, preventing electrical arcing and short circuits. This superior insulation property allows the transformer to operate safely at high voltage levels, which is essential for long – distance power transmission and large – scale power distribution.

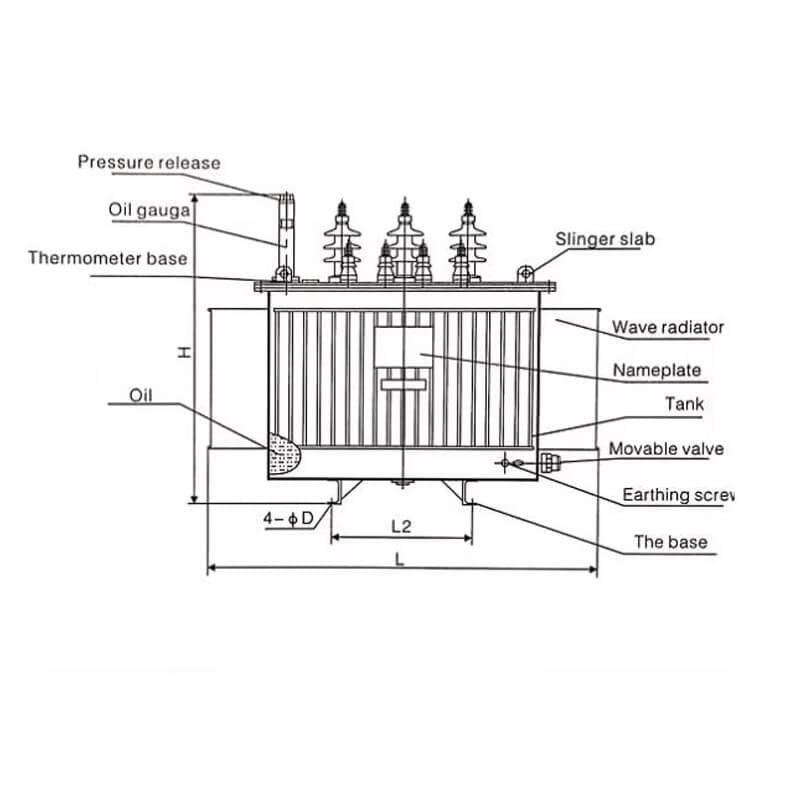

When it comes to heat dissipation, transformers generate a significant amount of heat during operation due to resistive losses in the windings and core losses. The oil circulates within the transformer tank, absorbing this heat. As the heated oil rises, it comes into contact with the cooling fins or radiators attached to the tank, where it releases the heat into the surrounding air. This efficient heat transfer mechanism ensures that the transformer operates within its optimal temperature range, preventing overheating and extending its service life.

Compared to dry – type transformers, oil – immersed transformers have a higher power density. This means they can deliver more power in a relatively smaller footprint, making them ideal for applications where space is limited, such as in urban substations and industrial facilities.

Three Phase Technology: Meeting the Demands of Modern Power Systems

Three phase power systems have become the standard in industrial and commercial applications due to their efficiency and ability to deliver a constant power output. High voltage three phase oil immersed transformers are specifically designed to work with these systems, offering several key benefits.

One of the main advantages of three phase technology is balanced load distribution. In a three phase system, the electrical load is evenly distributed across the three phases, reducing the stress on individual components. This balanced loading results in more efficient operation, lower energy losses, and increased reliability. It also allows for the use of smaller conductors compared to single – phase systems, reducing material costs and installation complexity.

Three phase transformers also provide a smoother power supply. The three alternating currents in a three phase system are offset by 120 degrees, resulting in a constant combined power output. This smooth power flow is crucial for sensitive industrial equipment, such as motors, pumps, and compressors, which rely on a stable power supply to operate efficiently and avoid damage.

In addition, three phase oil immersed transformers are highly adaptable to varying load conditions. They can handle both linear and non – linear loads, making them suitable for a wide range of applications, from traditional manufacturing plants to modern data centers with a high concentration of electronic devices.

Applications: Powering Critical Sectors

High voltage three phase oil immersed power and distribution transformers find applications in a diverse range of sectors, each with unique requirements.

In the power transmission and distribution sector, these transformers are used in substations to step up the voltage of electricity generated at power plants for long – distance transmission. Higher voltages reduce the current, which in turn reduces resistive losses in the transmission lines, making the transmission process more efficient. At the receiving end, the transformers step down the voltage to a level suitable for distribution to industrial, commercial, and residential users.

The industrial sector heavily relies on these transformers to power large – scale machinery and equipment. Industries such as manufacturing, mining, oil and gas, and chemical processing require high levels of power to operate their processes. High voltage three phase oil immersed transformers provide a reliable and efficient power supply, ensuring uninterrupted production. For example, in a steel mill, these transformers supply power to large electric arc furnaces and rolling mills, which demand high levels of electricity.

In the renewable energy sector, as the world shifts towards cleaner sources of energy, high voltage three phase oil immersed transformers play a vital role in integrating renewable energy sources such as wind and solar into the grid. Wind farms and solar power plants generate electricity at low voltages, which needs to be stepped up by transformers for transmission to the grid. These transformers are designed to handle the variable output of renewable energy sources, ensuring a stable and reliable supply of electricity.

Maintenance and Longevity: Ensuring Reliable Performance

To ensure the long – term reliability and performance of high voltage three phase oil immersed power and distribution transformers, regular maintenance is essential.

One of the key maintenance tasks is monitoring the condition of the insulating oil. Over time, the oil can become contaminated with moisture, dirt, and oxidation products, which can reduce its dielectric strength and heat dissipation capabilities. Regular oil sampling and testing, including measurements of dielectric strength, water content, and acidity, can help identify potential issues early. If necessary, the oil can be filtered or replaced to restore its properties.

Inspecting the transformer’s tank, windings, and core for signs of damage is also important. This includes checking for leaks in the tank, which can lead to oil loss and reduced insulation. The windings should be inspected for signs of overheating, such as discoloration or insulation degradation, and the core should be checked for loose laminations, which can cause increased core losses.

Regular testing of the transformer’s electrical parameters, such as insulation resistance, turns ratio, and short – circuit impedance, is another crucial maintenance activity. These tests can help detect problems such as insulation breakdown, winding faults, and core issues, allowing for timely repairs.

With proper maintenance, high voltage three phase oil immersed power and distribution transformers can have a service life of 20 to 30 years or more, providing a cost – effective solution for power distribution.

Conclusion: The Backbone of Modern Power Distribution

High voltage three phase oil immersed power and distribution transformers are the backbone of modern power systems, combining advanced oil immersion technology with three phase functionality to deliver efficient, reliable, and safe power distribution. Their ability to handle high voltages, dissipate heat effectively, and adapt to varying load conditions makes them indispensable in a wide range of applications, from power transmission and industrial processes to renewable energy integration.

By understanding their core design, advantages, and maintenance requirements, we can ensure that these transformers continue to play a vital role in powering our modern world. Whether in a large – scale power plant, an industrial facility, or a renewable energy project, high voltage three phase oil immersed power and distribution transformers are essential for meeting the growing demand for electricity.

Reviews

There are no reviews yet.