75kVA Transformer Specifications: Voltage, Phase, Cooling & Protection Options?

Grappling with the 75kVA Transformer Specifications? You’re not alone—even seasoned engineers and project managers often find the array of options daunting. Choose incorrectly, and you risk inefficiency, elevated costs, or even critical system failures.

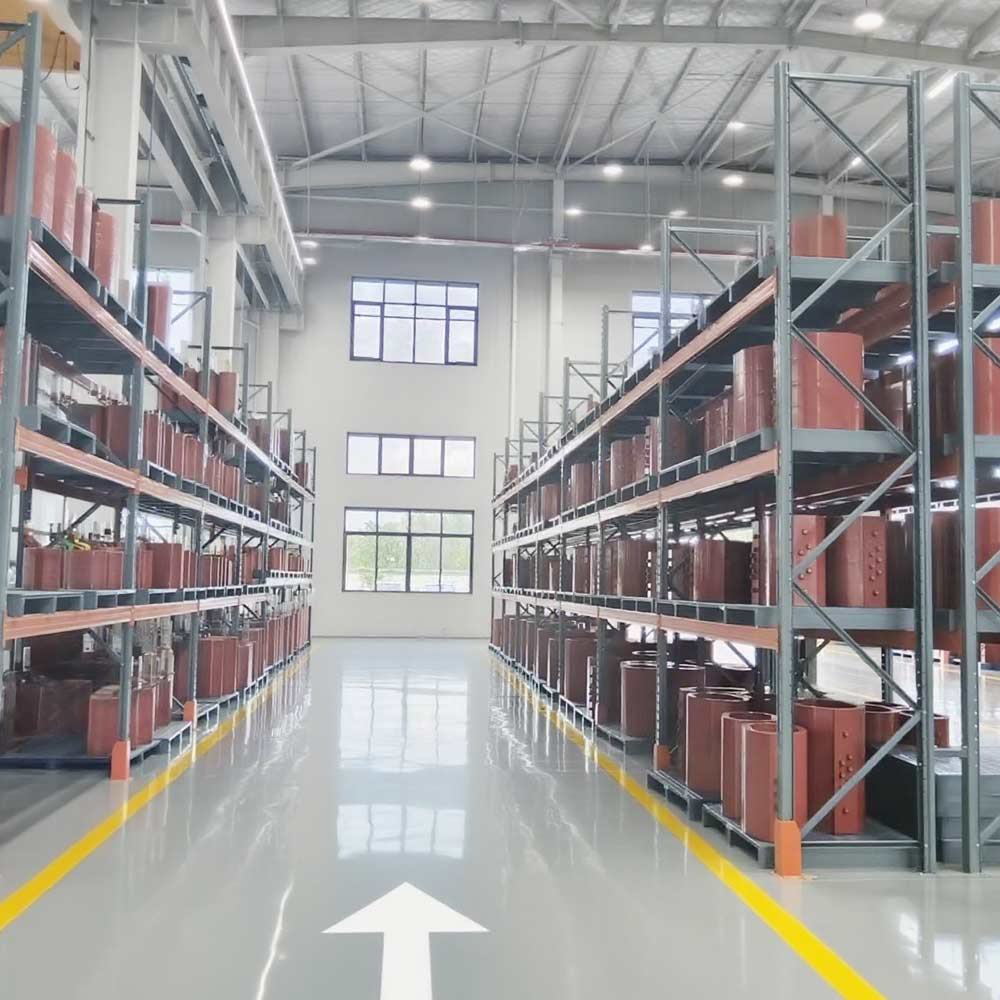

At Lihe Transformer—your trusted partner in high-performance transformer design and manufacturing—we specialize in demystifying these complexities. Our 75kVA transformers are engineered with customizable specifications, including voltage configurations (e.g., 480V/208Y-120V), single/three-phase setups, cooling systems (dry-type cast resin or oil-immersed), integrated protection devices, and versatile housing solutions. Every choice aligns with your application needs, environmental conditions, and compliance with global standards like IEC, ANSI, and IEEE.

In this guide, Lihe Transformer breaks down the key specifications to help you make informed decisions—whether you’re upgrading existing infrastructure, planning a new project, or navigating technical requirements for the first time.

1 Voltage Options: Primary and Secondary Common Configurations?

Unsure which voltage configuration suits your 75kVA transformer? The right primary and secondary voltage pairing is critical for system efficiency, compatibility with equipment, and seamless power distribution. Lihe Transformer’s engineering team simplifies this choice by aligning configurations with your power source and load demands.

Lihe Transformer’s 75kVA transformers offer flexible voltage options: common primary voltages include 480V, 4160V, and 13800V, while secondary options typically range from 208Y/120V to 480Y/277V. Custom voltage solutions are also available for unique project requirements, ensuring perfect integration with your existing setup.

Key Voltage Configurations & Lihe’s Applications

- Primary Voltage Choices:

- 480V: Ideal for commercial buildings and light industrial facilities (Lihe’s go-to for retail centers and small factories).

- 4160V: Designed for large industrial operations, minimizing line losses in heavy-load environments.

- 13800V: Tailored for utility distribution systems, connecting power grids to regional networks.

- Secondary Voltage Solutions:

- 208Y/120V: Perfect for commercial spaces, powering lighting, HVAC, and standard receptacles.

- 480Y/277V: Engineered for industrial machinery and high-capacity commercial loads (e.g., data centers).

- Transformation Ratios: Lihe Transformer optimizes ratios like 480V→208Y/120V (commercial step-down) and 4160V→480Y/277V (industrial distribution) for maximum efficiency.

- Custom Configurations: For specialized projects, Lihe delivers 240/120V setups (residential/light commercial) or bespoke voltages to meet unique load needs.

| Primary Voltage | Secondary Voltage | Lihe Transformer’s Typical Applications |

|---|---|---|

| 480V | 208Y/120V | Shopping malls, office buildings |

| 4160V | 480Y/277V | Manufacturing plants, industrial parks |

| 13800V | 480Y/277V | Utility grid distribution, regional supply |

| 480V | 240/120V | Small businesses, rural residential areas |

Lihe Transformer’s hands-on expertise shines in real-world projects. For a small manufacturing plant, our team initially evaluated a 480V primary but discovered the site’s power source was 4160V. We adjusted the configuration to a 4160V primary/480Y/277V secondary, eliminating the need for an extra step-down transformer and cutting costs by 15%.

Future expansion is another key consideration. For a commercial building with plans to add heavy equipment, we recommended a 480Y/277V secondary (instead of 208Y/120V) to support future load growth—ensuring the transformer remains viable for over a decade.

2 Single Phase vs Three Phase: What’s Better for 75kVA?

Deciding between single-phase and three-phase 75kVA transformers? This choice directly impacts efficiency, load capacity, and system compatibility. Lihe Transformer’s engineering team prioritizes matching phase configurations to your specific application, balancing performance and cost-effectiveness.

For 75kVA transformers, Lihe Transformer typically recommends three-phase configurations for industrial and large commercial use—thanks to their superior efficiency, balanced power distribution, and ability to handle heavy motor loads. Single-phase options, however, remain ideal for residential or light commercial settings with simpler load requirements.

Comparing Phase Configurations with Lihe Transformer

- Single-Phase 75kVA Transformers:

- Features: Simplified design, lower initial cost, and suitability for lighting, HVAC, and small appliances.

- Lihe’s Applications: Rural businesses, small retail stores, and residential complexes with limited three-phase power access.

- Three-Phase 75kVA Transformers:

- Advantages: Higher efficiency (up to 99.5% for Lihe’s models), better load balancing, and compatibility with industrial machinery.

- Lihe’s Applications: Manufacturing facilities, data centers, and large commercial buildings requiring stable power for heavy equipment.

- Load & Power Source Alignment:

- Single-phase: Best for sites with only single-phase utility supply and light, non-motor loads.

- Three-phase: Preferred for three-phase utility grids and loads like pumps, compressors, and production lines.

| Factor | Single-Phase | Three-Phase (Lihe’s Preferred for Most Uses) |

|---|---|---|

| Efficiency | Moderate (up to 97%) | High (up to 99.5%) |

| Typical Applications | Small retail, rural homes | Industrial facilities, data centers |

| Motor Load Handling | Limited | Excellent |

| Size/Weight | Larger, bulkier | Compact, space-saving |

| Long-Term Cost | Higher for large loads | Cost-effective for heavy, continuous use |

Lihe Transformer’s forward-thinking approach saved a client from costly upgrades. A small manufacturer initially considered a single-phase 75kVA transformer, but our team noted their plans to add three-phase machinery. We recommended a three-phase configuration upfront, avoiding a $10,000 upgrade just 12 months later.

For sensitive electronic equipment (e.g., precision instruments), Lihe’s three-phase transformers deliver superior voltage stability under fluctuating loads—reducing downtime and extending equipment lifespan.

3 Cooling Types: Dry Type (Cast Resin) vs Oil Immersed?

Choosing between dry-type (cast resin) and oil-immersed cooling for your 75kVA transformer? The right cooling system impacts safety, maintenance, and performance—especially in specific environments. Lihe Transformer offers both options, engineered to meet your installation location and operational needs.

Lihe Transformer’s dry-type (cast resin) 75kVA transformers excel in indoor, fire-sensitive settings (e.g., hospitals, data centers), while our oil-immersed models deliver superior cooling efficiency for outdoor or industrial applications. Each design adheres to strict safety and environmental standards.

Cooling System Comparison: Lihe’s Solutions

- Dry-Type (Cast Resin) Transformers:

- Advantages: Fire-resistant, eco-friendly (no oil leaks), low maintenance, and quiet operation.

- Lihe’s Applications: Hospitals, high-rises, and data centers—where fire safety and indoor installation are critical.

- Oil-Immersed Transformers:

- Benefits: Exceptional cooling efficiency, better overload capacity, and cost-effectiveness for outdoor use.

- Lihe’s Applications: Utility substations, industrial yards, and outdoor commercial sites.

- Environmental & Maintenance Considerations:

- Dry-type: No oil testing or containment needed; ideal for environmentally sensitive areas.

- Oil-immersed: Requires periodic oil analysis and leak prevention measures (Lihe uses biodegradable oil for eco-friendliness).

| Factor | Dry-Type (Cast Resin) | Oil-Immersed (Lihe’s Outdoor Go-To) |

|---|---|---|

| Fire Safety | High (no flammable materials) | Moderate (with fire-resistant safeguards) |

| Cooling Efficiency | Good (for indoor, moderate loads) | Excellent (for high loads, hot climates) |

| Environmental Risk | Low | Minimal (Lihe uses biodegradable oil) |

| Maintenance | Low (no oil checks) | Moderate (annual oil testing) |

| Typical Installation | Indoor, fire-sensitive areas | Outdoor, industrial sites |

Lihe Transformer prioritizes risk mitigation. For a data center, we rejected an oil-immersed transformer due to leak risks near sensitive electronics. Our dry-type model ensured safety while meeting the center’s 24/7 operational demands.

In extreme hot climates, Lihe’s oil-immersed 75kVA transformers maintain stable temperatures—critical for industrial facilities operating under heavy loads year-round.

4 Protection Devices: Surge Arresters, Fuses, Relays?

Safeguarding your 75kVA transformer from faults and surges is non-negotiable. Lihe Transformer integrates tailored protection devices—surge arresters, fuses, relays, and temperature monitors—to ensure longevity and reliability, regardless of application.

Lihe Transformer’s 75kVA transformers come standard with core protection features, with customizable upgrades for high-risk environments (e.g., coastal areas, industrial zones). Each device is calibrated to work seamlessly with the transformer’s specifications.

Lihe’s Protection Device Offerings

- Surge Arresters: Shield against lightning strikes and voltage spikes—critical for outdoor or coastal installations. Lihe’s weather-resistant arresters divert excess voltage to ground, preventing insulation damage.

- Fuses & Circuit Breakers: Lihe uses high-quality fuses (cost-effective for small systems) and circuit breakers (resettable, ideal for large setups) to protect against overloads and short circuits.

- Protective Relays: Advanced relays monitor temperature, oil level (for oil-immersed models), and current—triggering alarms or shutdowns to prevent catastrophic failure.

- Temperature Monitors: Winding and oil temperature sensors (Lihe’s proprietary design) prevent overheating, extending transformer life by up to 20%.

| Device | Function | Lihe’s Application Focus |

|---|---|---|

| Surge Arresters | Block voltage spikes/lightning | Coastal, outdoor installations |

| Fuses | Overcurrent protection (one-time use) | Small commercial systems |

| Circuit Breakers | Resettable overcurrent protection | Industrial, critical systems |

| Protective Relays | Advanced monitoring/alerts | Data centers, hospitals |

| Temperature Monitors | Prevent overheating | All installations (standard feature) |

Lihe Transformer’s protection schemes saved a coastal client from downtime. A severe thunderstorm hit their facility, but our surge arresters diverted lightning-induced voltage spikes—protecting the 75kVA transformer and avoiding $20,000 in damages.

For remote sites, Lihe offers self-monitoring protection devices with remote alerts—allowing clients to track transformer health without on-site visits.

5 Housing Options: Pad-Mounted, Pole-Mounted, Enclosed?

Selecting the right housing for your 75kVA transformer impacts installation, accessibility, and durability. Lihe Transformer offers three core housing options—pad-mounted, pole-mounted, and enclosed—each engineered for specific environments and space constraints.

Lihe’s pad-mounted 75kVA transformers suit urban, ground-level installations; pole-mounted models save space in rural areas; and enclosed designs provide extra protection for indoor or harsh environments. All housings are customizable to match aesthetic or regulatory requirements.

Lihe’s Housing Solutions & Applications

- Pad-Mounted Transformers:

- Features: Ground-level installation, landscapable design, and easy maintenance access.

- Lihe’s Applications: Residential developments, urban commercial areas—where aesthetics and accessibility matter.

- Pole-Mounted Transformers:

- Advantages: Space-saving, cost-effective, and ideal for overhead distribution systems.

- Lihe’s Applications: Rural communities, areas with existing overhead utility lines.

- Enclosed Transformers:

- Benefits: Weatherproof, corrosion-resistant, and suitable for indoor or polluted environments.

- Lihe’s Applications: Industrial zones, coastal areas, and indoor facilities (e.g., basement substations).

| Housing Type | Typical Location | Lihe’s Key Advantages |

|---|---|---|

| Pad-Mounted | Urban/suburban areas | Aesthetic, easy maintenance |

| Pole-Mounted | Rural, overhead grid areas | Space-saving, economical |

| Enclosed | Indoor, harsh environments | Weatherproof, secure, customizable |

Lihe Transformer adapted to a historic district’s strict regulations. A client needed a 75kVA transformer that wouldn’t disrupt the area’s historic character—we installed an underground enclosed model, hidden from view while delivering reliable power.

For flood-prone coastal sites, Lihe’s elevated pad-mounted housings (with waterproof enclosures) protect transformers from water damage—ensuring uninterrupted service during storms.

6 Compliance with IEC, ANSI, or IEEE Standards?

Navigating IEC, ANSI, and IEEE standards for your 75kVA transformer is critical for safety, global compatibility, and regulatory approval. Lihe Transformer designs all 75kVA transformers to meet or exceed these standards—tailoring compliance to your project’s geographic location and application.

Lihe’s 75kVA transformers adhere to IEC 60076 (international use), ANSI C57.12 (North American markets), and IEEE C57.12 (global guidelines for performance). Our engineering team ensures full compliance with design, testing, and safety requirements.

Key Standards & Lihe’s Compliance Approach

- IEC Standards:

- Focus: International design, testing, and performance requirements (e.g., IEC 60076 for power transformers).

- Lihe’s Application: Export projects, global clients—ensuring compatibility across Europe, Asia, and beyond.

- ANSI Standards:

- Requirements: North American-specific construction and performance (e.g., ANSI C57.12 for liquid-immersed/dry-type transformers).

- Lihe’s Application: U.S. and Canadian projects, meeting local utility and regulatory demands.

- IEEE Standards:

- Guidelines: Complementary to ANSI, covering testing and application (e.g., IEEE C57.12 for short-circuit withstand).

- Lihe’s Application: Industrial and utility projects requiring rigorous performance validation.

| Standard | Geographic Focus | Lihe’s Compliance Highlights |

|---|---|---|

| IEC 60076 | Global | Meets international export requirements |

| ANSI C57.12 | North America | Aligns with U.S./Canadian utility standards |

| IEEE C57.12 | Global (complementary to ANSI) | Rigorous short-circuit and efficiency testing |

Lihe Transformer simplified compliance for a multinational client. A company with operations in Europe and North America needed a 75kVA transformer that met both IEC and ANSI standards. Our team designed a dual-compliant model, eliminating the need for region-specific units and streamlining their supply chain.

For renewable energy projects, Lihe’s transformers comply with additional IEC standards for solar/wind integration—ensuring seamless compatibility with inverter systems and grid requirements.

7 Conclusion

Selecting the right 75kVA transformer specifications demands careful evaluation of voltage options, phase configurations, cooling systems, protection devices, housing solutions, and compliance standards. At Lihe Transformer, we combine technical expertise with customizable engineering to deliver transformers tailored to your unique needs—whether for commercial, industrial, or utility applications.

Our 75kVA transformers prioritize efficiency, safety, and reliability, backed by real-world project experience and adherence to global standards. By partnering with Lihe Transformer, you gain access to personalized guidance, high-quality manufacturing, and solutions designed to optimize your power distribution system for years to come.

CERTIFICATE

Related Products

Compact Box Transformer Substation for Urban Areas

Transformer BoxBox Type Prefabricated Transformer Substations for Residential

Transformer Box250 KVA European-style Box-type Transformer Substation

Transformer Box500 kva Compact Substation Green Transformer Box

Transformer Box